GEMÜ GEBRÜDER MÜLLER APPARATEBAU GMBH & CO. KG

Germany

Manufacturer/ Producer

GEMÜ GEBRÜDER MÜLLER APPARATEBAU GMBH & CO. KG

Germany

The GEMÜ 610 2/2-way diaphragm valve has a low maintenance plastic piston actuator and is pneumatically operated. An integral optical position indicator is standard. Normally Closed (NC), Normally Open (NO) and Double Acting (DA) control functions are available. —Same mounting height planes over multiple nominal sizes —Compact plant design due to flow optimised valve bodies —Integral optical position indicator and seal adjuster as standard —Option with electrical position indicator and / or lock out device

Request for a quote

GEMÜ GEBRÜDER MÜLLER APPARATEBAU GMBH & CO. KG

Germany

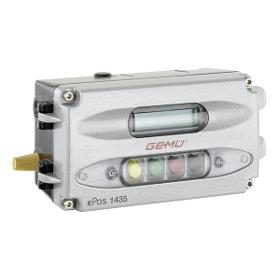

The GEMÜ 1435 ePos digital electro-pneumatic positioner detects the valve position via its external travel sensor. It has a solid housing with protected operating buttons and an easy to read LC display. The operating times can be set by integrated throttles. Connection and mounting to NAMUR is also possible. —Simple handling and commissioning —Simple electrical connection by detachable terminals —Automatically optimises the valve control during initialisation —No air consumption when idle

Request for a quote

GEMÜ GEBRÜDER MÜLLER APPARATEBAU GMBH & CO. KG

Germany

The GEMÜ 4242 combi switchbox is suitable for mounting to pneumatically operated linear actuators. It utilises a microprocessor controlled, intelligent position sensor and an analogue travel sensor system. The combi switchbox was specially designed for small to medium nominal sizes and strokes ranging from 2 to 30 mm. The combi switchbox has an integrated 3/2-way pilot valve. —Standard OPEN and CLOSED feedback —Speed-AP function for fast mounting and initialisation —High visibility position indicator —Adjustable switch point tolerances —Extensive diagnostic facilities —Local or remote programming via programming input —Simple and fast mounting —Can be retrofitted to GEMÜ valves or third-party actuators

Request for a quote

GEMÜ GEBRÜDER MÜLLER APPARATEBAU GMBH & CO. KG

Germany

The GEMÜ N082, N182 and N782 pressure reducers ensure that a constant outlet pressure is maintained in process plant utilizing the pressure differential.If the pressure rises on the outlet side, the spring force is lower and the valve closes as the spring is raised. The pressure is reduced until the spring force and the outlet pressure are the same. If the pressure falls, the valve opens as the spring force presses against the diaphragm surface via the control aperture. The outlet pressure can be read off a diaphragm-protected pressure gauge (not available for N782) and the spring force adjusted using a set screw as required. - The working pressure can be very easily adjusted using a set screw and secured with the integrated lock nut. If required, the setting that has been made can be lead sealed - The flow-efficient design of the valve body ensures good flow rate values - Control errors are kept to a minimum due to the large control face and the spiral spring

Request for a quote

GEMÜ GEBRÜDER MÜLLER APPARATEBAU GMBH & CO. KG

Germany

Fittings Our manufacturing site in Switzerland produces over 100 different types of fitting under cleanroom conditions in compliance with DIN 16901-140. The fitting bodies are made of PFA, while the union nuts are made of PFA, PVDF or CPFA. We stock all the connections available on the market too. Emmen cleanroom plant GEMÜ has be producing valves and fittings at its new cleanroom plant in Emmen (Canton of Lucerne, Switzerland) since September 2012. A state-of-the-art manufacturing and assembly facility was built here when, thanks to commercial success, the capacity of our site in Rotkreuz could no longer keep up with demand. When planning and developing the facility, designers focused on creating a contemporary quality management system that is fit for the future. The result is that product and production quality are ensured, for example, by using specific inspected raw materials and through audits carried out by customers and official bodies.

Request for a quote

GEMÜ GEBRÜDER MÜLLER APPARATEBAU GMBH & CO. KG

Germany

The pressure relief valves GEMÜ N085 and N185 protect the plant and the piping system against gauge pressure and reduces pressure peaks. The third pipe spigot enables the valve to be installed in the main pipe. If the pressure increases, the spring is raised and the valve opens. The pressure is reduced to the preset value and can escape via the third pipe spigot into an adjacent pipe. If the pressure falls, the spring force presses the diaphragm in the direction of the seal seat and it is closed. The spring force can be adjusted as required using a set screw. - Valve adjustments can also be made under working pressure. - The optimization of piston, springs and control face ensures good control characteristics - The actuator is hermetically separated from the medium

Request for a quote

GEMÜ GEBRÜDER MÜLLER APPARATEBAU GMBH & CO. KG

Germany

The GEMÜ 498 PTFE seated butterfly valve is motorized. Various metal or plastic on/off or control actuators are available. Disc and shaft are one-piece, body and seat are available in different designs. The butterfly valve is available in nominal sizes DN 40 - 900 (1½? - 36?) and in wafer and lugged body versions. —Suitable for isolating and control functions with gaseous and liquid media —Seal material TFM™ (FDA 21CRF 177.1550) —Installation length acc. to ISO 5752/20, EN 558-1/20, JIS 10K

Request for a quote

GEMÜ GEBRÜDER MÜLLER APPARATEBAU GMBH & CO. KG

Germany

The GEMÜ 1436 cPos is a digital electro-pneumatic positioner with optionally integrated process controller for the control of pneumatically operated process valves. When using the optional process controller the signals from a process sensor (e.g. flow, level, pressure, temperature) are detected and the media adjusted according to the specified set value. The positioner has a solid housing with protected operating buttons and a LC display. —Digital inputs (option) for variable function control for automation —Fieldbus interfaces e.g. Profibus DP, DeviceNet (option) —No air consumption when idle —Simple mounting to various valve actuators —Access rights via different user levels

Request for a quote

GEMÜ GEBRÜDER MÜLLER APPARATEBAU GMBH & CO. KG

Germany

The GEMÜ PFA tubing range comprises tubing spools and straight tube pieces. These can be supplied either in a high-purity version with Teflon® PFA 450 HP (DuPont) or in the standard version. Depending on availability, the latter uses PFA M620, Dyneon 6502T or Daikin MP-230. The tubes are available in standard lengths as rolls (10 m, 20 m, 50 m, 100 m) and 6 m tube pieces. The following sizes can be ordered: 1/4", 3/8", 1/2", 3/4", 1", 1 1/4". Other sizes and lengths (min. 110 m overall length) are available as special versions. Advantages: — High-purity version complies with SEMI F57 and has FDA approval for food-related applications — Excellent pressure resistance and high flexural fatigue strength — Suitable for temperatures up to 170 °C.

Request for a quote

GEMÜ GEBRÜDER MÜLLER APPARATEBAU GMBH & CO. KG

Germany

The GEMÜ SUMONDO® single-use diaphragm valve consists of a diaphragm valve body and a manual or pneumatic operator. The single-use diaphragm valve body has an internally welded diaphragm. The single-use diaphragm valve body is fastened to the operator using a clamp. The valve body and the operator are locked using a defined closing and opening procedure. After use, the single-use diaphragm valve body and its diaphragm can be removed from the operator and disposed of. The operator can be used multiple times and remains in the plant. — Tried and tested actuator design — Impact resistant, corrosion resistant — The diaphragm valve body meets the purity requirements of the pharmaceutical industry (USP 85, USP 788) — Integral optical position indicator — Validation Guide on request — Gamma-sterilizable valve body

Request for a quoteManufacturer/ Producer

Fritz-Müller-Straße 6-8

74653 Ingelfingen - Germany