- europages

- >

- Forming- rubber - machinery

- >

- QUELLTECH GMBH

- >

- Laser Sensor for Seal Surface Inspection

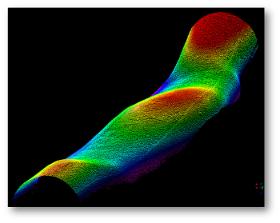

Laser Sensor for Seal Surface Inspection

Testimonial: Inline Quality Check

Description

Particular Challenges: The seal surfaces in this case are made of very glossy metal, with the drawback of emitted reflections. This effect during an optical measurement must be eliminated. Furthermore, it is absolutely necessary to guide the laser scanner on a linear path over the surface, since fluctuations of distance may falsify the measurement result. QuellTech Solution: The Quelltech model Q5 disposes of an adequate resolution in X and Z direction and proves to be able to verify the planarity tolerances and to measure the size of defects. Meanwhile a precise rotary axle, used as guiding element, moves the scanner over the surface to be evaluated. Interfering artefacts caused by the glossy finish are suppressed by particular algorithms integrated within the software. As an encoder value is permanently supplied by the rotary axle, the position of each scanner profile within the point cloud can accurately be determined.

- Forming, rubber - machinery

- inspection of seal surface

- 100 % inline inspection

- find artefacts

Similar products from QUELLTECH GMBH

QUELLTECH GMBH

Germany

Particular Challenges: In the course of the production, endless cables are running at a considerable speed, and supervision has to be carried out nearly under real-time conditions. The size of the objects to be determined, i.e. of the flaws to be discovered, is in the range of only some hundredths of a mm. Another difficulty is the fact that surfaces with very different reflectivity and roughness are involved. In order to be able to check the cables all around, several laser scanners must be in place, mounted at different angles, thus covering the entire range of 360°. Quelltech Solution: The solution consists in a configuration of four Q6 laser scanners, mutually displaced by 90°, so the entire surface of the cables is in the field of view. On the basis of the 100% inline inspection, the position of defects can precisely be determined, without losing too much time.

Request for a quote