- europages

- >

- Die casting moulds

- >

- EUROBALT ENGINEERING OÜ

- >

- ADVANTAGES AND DISADVANTAGES OF DIE CASTING

ADVANTAGES AND DISADVANTAGES OF DIE CASTING

USEFUL INFORMATION FOR CUSTOMERS

Description

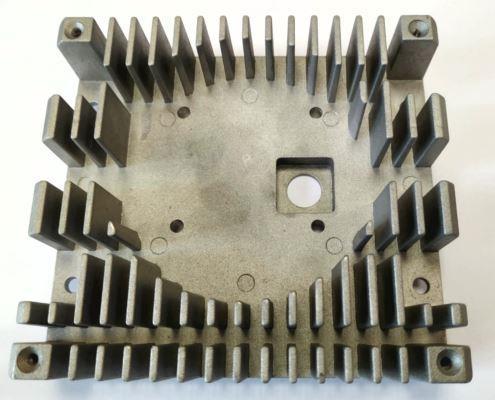

Metal die casting – is a production technology of castings, in which the alloy under pressure up to 700 MPa quickly fills the mold. Products made in this way can be of different sizes and have weigh up to several kilograms. As a basic raw material normally are used following: non-ferrous metals — copper, aluminum, and their alloys. Die casting makes it possible to obtain high-precision products (along with such technology as powder metallurgy, which allows to obtain sintered metal parts that are particularly hard and wear-resistant). Our company offers the manufacture of parts for LED lighting and other high quality castings. One of the main advantages of die casting is the resistance of finished products to corrosion. The fact is that in the process of their manufacture a strong surface crust is formed, which has a high density and low moisture permeability.

- Die casting moulds

- diecasting

- Aluminium die casting

- aluminium die-casting

Similar products from EUROBALT ENGINEERING OÜ

EUROBALT ENGINEERING OÜ

Estonia

Eurobalt Engineering provides die casting services for the companies that manufacture lighting products for different industries. Our company mainly produces street lamp housings and cooling radiators using aluminium alloys for LED lighting systems manufacturers. Our die casting services are exceptionally cheap and high-quality – aluminium parts turn out cheaper than if similar parts are produced using other methods. Although aluminium die casting parts are not so durable and long-lasting, they are also lighter and have a high thermal conductivity, which is very important in the production of LED lighting systems.

Request for a quote

EUROBALT ENGINEERING OÜ

Estonia

We provide the die casting manufacturing with a wide range of advantages for our clients: Excellent dimensional accuracy Smooth cast surfaces Thinner walls can be cast as compared to sand and permanent mold casting Fast production cycle times Reduces or eliminates secondary machining operations Rapid production rates Casting of low fluidity metals Long tool life, especially for zinc and magnesium Our production line provides manufacturing casted parts like Transmission gearbox housing, LED Housing, Oil pans, Engine blocks, Light boxes and other custom parts according to your drawings.

Request for a quote