AMSBECK MASCHINENTECHNIK GMBH -

Germany

Manufacturer/ Producer

AMSBECK MASCHINENTECHNIK GMBH

Germany

Product characteristics of the centrifugal brakes The centrifugal brake generally works like a centrifugal clutch, but with the housing secured against twisting. A centrifugal brake generally does not brake to standstill but only keeps the revolutions constant. Typical applications for centrifugal brakes are roping-down devices, cranes, lifts, safety gates, and also speed limiters. Areas of use for centrifugal brakes Centrifugal brakes are often used as backup brake systems for electronic brakes. They have the advantage of braking reliably and securely, independently of any other power supply. We supply the centrifugal brake without a housing if the customer already has a brake housing, too.

Request for a quote

AMSBECK MASCHINENTECHNIK GMBH

Germany

The centrifugal clutch with pulley, like the centrifugal clutch with automatic belt tensioners, offers the benefit of a compact build in which an additional tensioning roller is not needed in the belt drive. In the centrifugal clutch with adjustment disc, the drum is formed as a regulating hub. The regulating hub adjusts the belt pre-tension. The regulating nut is secured with grub screws in the adjustment area and can be set smoothly. These centrifugal clutches are also used in shaker plates.

Request for a quote

AMSBECK MASCHINENTECHNIK GMBH

Germany

The centrifugal clutch with belt output is the most frequently used build of Amsbeck centrifugal clutches. This type of centrifugal clutch has the pulley installed in the clutch bell already. This leads to a compact and space-saving, as well as cost-efficient, build. A centrifugal clutch with belt output can generally use any standardised belt profile and pulley diameter. The number of belt grooves can be chosen freely as well. Of course, a centrifugal clutch with belt output can also be delivered with special belt profiles and V-rib belt profiles at the customer's request. We also offer matching counter-pulleys on request."

Request for a quote

AMSBECK MASCHINENTECHNIK GMBH

Germany

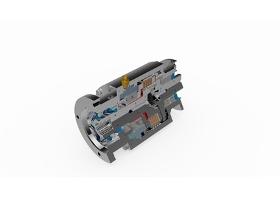

Product characteristics of the Disc clutches The shifting clutches mostly serve as a connection that can be activated or disconnected between the power and work units, such as the gear and pump, or in similar installation situations. The disconnection is achieved via the system's existing media supply. (hydraulics, pneumatics) Areas of use of Disc clutches The disc clutches are used in mobile applications, agricultural and forestry machines, sweeping machines and many other areas in mechanical engineering.

Request for a quote

AMSBECK MASCHINENTECHNIK GMBH

Germany

The centrifugal clutch with perforation enables customers to attach special output elements, such as sprockets, pulleys and articulated shafts or flanges, etc. This way, the centrifugal clutch can be designed individually and precisely fitting. We generally build two different types of centrifugal clutches: One is the standard clutch with profile hub. The other, for special applications, is the centrifugal clutch in the rotating jaw version. This special centrifugal clutch is outstandingly suitable for applications with high oscillations or very high loads.

Request for a quote

AMSBECK MASCHINENTECHNIK GMBH

Germany

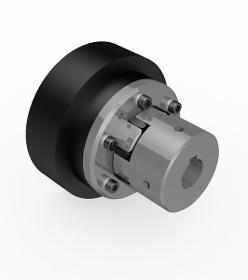

A centrifugal clutch with highly elastic clutch is used for applications where rotating oscillations may occur in addition to the shaft offset. In this case, centrifugal clutches must be used with flange-connected highly-elastic clutch elements. This specifically includes compressor systems and silo vehicles. We generally build two different types of centrifugal clutches: One is the standard clutch with profile hub. The other, for special applications, is the centrifugal clutch in the rotating jaw version. This special centrifugal clutch is outstandingly suitable for applications with high oscillations or very high loads.

Request for a quote

AMSBECK MASCHINENTECHNIK GMBH

Germany

For centrifugal clutches with belt outputs, the belts must be pre-tensioned in order to maintain the pressing force required to transfer force. Usually, tensioning rollers are used in the belt drive for this purpose. However, tensioning rollers are hard to use with short axle distances. The tried-and-tested centrifugal clutch with integrated, automatically acting belt tensioner compensates the length changes of the V-belts by adjusting the diameter of the pulley. Typically, these centrifugal clutches are used in high-quality reversible shaker plates.

Request for a quote

AMSBECK MASCHINENTECHNIK GMBH

Germany

We recommend a centrifugal clutch in combination with an elastic clutch to effectively compensate for the arising shaft offset. This design of a centrifugal clutch is frequently used in pump drives. We generally build two different types of centrifugal clutches: One is the standard clutch with profile hub. The other, for special applications, is the centrifugal clutch in the rotating jaw version. This special centrifugal clutch is outstandingly suitable for applications with high oscillations or very high loads.

Request for a quote

AMSBECK MASCHINENTECHNIK GMBH

Germany

In this centrifugal clutch, the output takes place through a sprocket. We offer a broad range of sprockets for this type of centrifugal clutch, including a version ex-stock for cart sports. We generally build two different types of centrifugal clutches: One is the standard clutch with profile hub. The other, for special applications, is the centrifugal clutch in the rotating jaw version. This special centrifugal clutch is outstandingly suitable for applications with high oscillations or very high loads.

Request for a quote

AMSBECK MASCHINENTECHNIK GMBH

Germany

The centrifugal clutch without housing is used when the customer already has a housing. In that case, the centrifugal clutch will be delivered without a bell. A vibration tamper would be one typical application for a centrifugal clutch without a housing. We generally build two different types of centrifugal clutches: One is the standard clutch with profile hub. The other, for special applications, is the centrifugal clutch in the rotating jaw version. This special centrifugal clutch is outstandingly suitable for applications with high oscillations or very high loads.

Request for a quoteManufacturer/ Producer

Boschweg 15

48351 Everswinkel - Germany

europages also recommends

A selection of companies related to the activity:

A selection of products that might interest you

Request for quotes

Create one request and get multiple quotes form verified suppliers.

- Only relevant suppliers

- Data privacy compliant

- 100% free