BEDIA MOTORENTECHNIK GMBH & CO. KG - Messen mit System und Leidenschaft

Germany

Manufacturer/ Producer

BEDIA MOTORENTECHNIK GMBH & CO. KG

Germany

Areas of Application and Advantages BEDIA CLS 10 stands for special versions of our well-proven CLS 40 series for heavy duty applications. Currently, the BEDIA CLS 10 series includes a variety of sensors, which are compatible replacement parts for level switches from Cooper Standard and Robert Shaw which are obsolete nowadays – and this in well proven BEDIA quality. This also includes sensors with 2 complementary CMOS outputs. It should be emphasized that the water sensors with two complementary outputs can be operated with a supply voltage of 4.75 V DC – 32 V DC. Operating Principle The function of the sensor is based on the capacitive principle. It detects the change in capacitance that arises when an electrode surrounded by air is immersed into a liquid medium. This change in capacitance at the electrode of the sensor excites an oscillator, causing it to oscillate (at a frequency of approx. 600 kHz). Then this signal is processed by a microprocessor-based evaluation circuit.

Request for a quote

BEDIA MOTORENTECHNIK GMBH & CO. KG

Germany

BEDIA level monitoring sensors are used to monitor the filling levels of liquids. The sensors detect when a filling level is exceeded or falls below a limit. Water-based liquids like coolants, AdBlue®, fresh water, waste water and oil-based liquids like motor oils, hydraulic oils, fuels and brake fluids can be monitored. Operating Principle The function of the sensor is based on the capacitive principle. It detects the change in capacitance that occurs when an electrode surrounded by air is immersed into a liquid medium. This change in capacitance at the electrode of the sensor excites an oscillator. This signal is processed by a microcontroller-based evaluation circuit which activates or deactivates an output stage. Types of Media The level monitoring sensors are designed for two different media types: For electrically conductive liquid media with relative permittivity within a range of εr 35 … 85 (water, coolant, water/glycol mixture) For electrically non-conductive liquid media

Request for a quote

BEDIA MOTORENTECHNIK GMBH & CO. KG

Germany

BEDIA level monitoring sensors are used to monitor the filling levels of liquids. The sensors react when a filling level is exceeded or falls below a limit. Aqueous mediums like coolants, AdBlue®, fresh water, waste water, bilge water and oil-based liquids like motor oils, hydraulic oils, fuels and brake fluids can be monitored. Since they contain no mechanical moving parts, their function will not be influenced by dirt particles or other influences. No electrical current is sent through the medium via an electrode with BEDIA sensors, an electrolysis of the medium is not possible. Operating Principle The function of the sensor is based on the capacitive principle. It detects the change in capacitance that arises when an electrode surrounded by air is immersed into a liquid medium. This change in capacitance at the electrode of the sensor excites an oscillator, causing it to oscillate. Then this signal is processed by a microprocessor-based evaluation circuit.

Request for a quote

BEDIA MOTORENTECHNIK GMBH & CO. KG

Germany

BEDIA level monitoring sensors are used to monitor the filling levels of liquids. The sensors detect when a filling level is exceeded or falls below a limit. Water-based liquids like coolants, AdBlue®, fresh water, waste water, bilge water and oil-based liquids like motor oils, hydraulic oils, fuels and brake fluids can be monitored. Since they contain no mechanical moving parts, their function will not be influenced by dirt particles or other influences. No electrical current is sent through the medium via an electrode with BEDIA sensors, an electrolysis of the medium is not possible. Operating Principle The function of the sensor is based on the capacitive principle. It detects the change in capacitance that occurs when an electrode surrounded by air is immersed into a liquid medium. This change in capacitance at the electrode of the sensor excites an oscillator. This signal is processed by a microcontroller-based evaluation circuit which activates or deactivates an output stage.

Request for a quote

BEDIA MOTORENTECHNIK GMBH & CO. KG

Germany

BEDIA intelligent tank sensor ITS 60 is used to monitor the filling levels of Diesel fuels. The sensor is able to automatically recognize what kind of Diesel fuel (Bio-Diesel, Summer-/Winter-Diesel etc.) is present and calibrates itself to it. The capacitative measurement principle permits measurement of levels without mechanically moving parts. This considerably increases stability and operating safety. Mechanics The new tank sensor ITS 60 is characterized by a particularly stable, but light mechanical system specially designed for “Heavy Duty Applications”. The mounting flange and measurement tube are constructed from die cast aluminium. This construction permits the insertion of tank sensors up to 1200 mm in length, without additional support on the tank floor. The flange hole distribution is compatible with commercially used tank sensors. This means that this system can be used without expensive conversions.

Request for a quote

BEDIA MOTORENTECHNIK GMBH & CO. KG

Germany

BEDIA intelligent tank sensor ITS 65 is used to monitor the filling levels of oils of any kind. The sensor is able to automatically recognize and what kind of oil (hydaulic oil, engine oil etc.) is present and calibrates itself to it. The capacitative measurement principle permits measurement of levels without mechanically moving parts. This considerably increases stability and operating safety. Mechanics The new tank sensor ITS 65 is characterized by a particularly stable, but light mechanical system specially designed for “Heavy Duty Applications”. The mounting flange and measurement tube are constructed from die cast aluminium. This construction permits the insertion of tank sensors up to 1200 mm in length, without additional support on the tank floor. Analogue Output The analogue output is available as an voltage output with a range from 0 V to 10 V or as an PWM output.

Request for a quote

BEDIA MOTORENTECHNIK GMBH & CO. KG

Germany

These high-power bimetal operated temperature switches are available either with normally closed (NC) or normally open (NO) contact configuration. The robust round metal enclosure accommodates a resilient preloading disk, a bimetal disk and a silver contact. The compact switch system is covered by means of a plate which also carries a silver contact and is isolated from the enclosure by means of an isolating washer. The resilient preloading disk ensures excellent performance. The resilient preloading disk keeps the contact pressure constant throughout the entire temperature range of the BEDIA switch until switching occurs. The mechanically and electrically unloaded bimetal disk snaps over at a preset temperature, with either opening or closing the contact arrangement. The bimetal will only snap back to its initial condition after the temperature has dropped significantly.

Request for a quote

BEDIA MOTORENTECHNIK GMBH & CO. KG

Germany

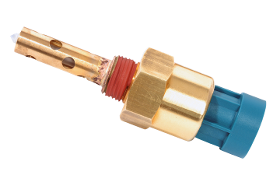

The electronic temperature switch of BEDIA is fitted with thin-film resistor Pt 1000 in a bridge circuit. This sensor element provides close switch point tolerances and a quick response. Switch point and reset hysteresis may be selected within the admissible operating range when ordering so as to allow the monitoring of both very wide and very close temperature ranges. The switching output is protected from short-circuit and overload. The short-circuit current is limited by the output transistor switching off inthe event of a fault. It will automatically reset as soon as the fault has been remedied. The switch is available with ground-connected, plus-connected or potential-free DC switching output. The switch is open in the event of power failure or disconnection of the power supply, independed of the switching function. It is available both as normally open (NO) or normally closed (NC) switch.

Request for a quote

BEDIA MOTORENTECHNIK GMBH & CO. KG

Germany

This temperature sensor is for measuring the temperature of liquid and gaseous media in engines, sets of machines and utility vehicles. A Pt 1000 thin-film precision resistor is used as the measuring element. The temperature-dependent resistance of the Pt 1000 is evaluated by an electronic circuit and outputted as a temperature-dependent voltage at the sensor‘s output. The interrelationship between temperature and voltage corresponds to the characteristic curve for the Pt 1000 and is thus nearly linear. The assignment between temperature and output voltage is nearly freely selectable, the lesser temperature corresponding to the lesser output voltage. The sensor‘s lowest possible output voltage is 0.1 V and its greatest is 10 V. The output is overload-proof and short-circuit-proof. The sensor has no mechanical moving parts and so is not susceptible to vibration and soiling.

Request for a quote

BEDIA MOTORENTECHNIK GMBH & CO. KG

Germany

Temperature is one of the most measured physical parameters. Despite this, precise temperature measurement is one of the most difficult tasks in motor technology. To meet the constantly increasing requirements for improved motor performance, higher efficiency and reduced emissions, it is necessary to use reliable and precise sensors in modern motor control systems. The increased requirements over the last few years regarding measurement accuracy and reliability of temperature measurements has meant that many equipment operators must reconsider the suitability and performance capacity of their temperature measurement equipment. Resistant thermometers can be used between -200 °C and +850 °C. An important common property is that their output parameters are available in the form of electric signals that can be relatively easily transferred to measurement and control instruments for processing, storage and display.

Request for a quoteManufacturer/ Producer

Im Erlet 1

90518 Altdorf - Germany