- europages

- >

- Plumbing- industrial

- >

- BORSIG GMBH

- >

- products

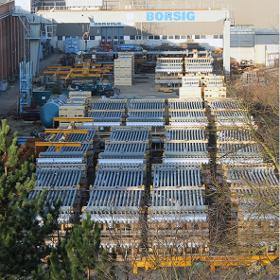

BORSIG GMBH - LEADING TECHNOLOGY FOR INNOVATIVE SOLUTIONS

Germany

Manufacturer/ Producer

BORSIG GMBH

Germany

BORSIG manufactures reformed gas waste heat boilers for more than 50 years. We supply reformed gas waste heat boilers for gas inlet temperatures of up to 1,200°C and steam pressures of up to 160 bar (16,000 kPa) for petrochemical industry (ammonia plants, methanol plants, hydrogen plants, ethylene plants, styrene plants, MTBE plants, oxo-alcohol plants, direct reduction iron plants, coas gasification plants, gas to liquid plants, and others. Every reformed gas waste heat boiler is designed and manufactured exactly in accordance with the customer´s individual requirements. BORSIG offers two different designs: 1. Reformed gas waste heat boilers with BORSIG´s thin stiffened tube sheet design 2. Reformed gas waste heat boilers with thin flexible tube sheet design.

Request for a quote

BORSIG GMBH

Germany

BORSIG patented steam superheaters are suitable for steam pressures of up to 160 bar (16,000 kPa). The steam superheaters are arranged direct in line after the waste heat boilers which are connected to the secondary reformer or reformer – depending on the process. The steam superheater can be provided as two stage or one stage, horizontally or vertically arranged. The final design arrangement is determined by the process requirements. We have delivered steam superheaters for superheating saturated steam at a pressure stage of 12,500 kPa from 328 °C to 531 °C by cooling down process gas from 723 °C to 355 °C.

Request for a quote

BORSIG GMBH

Germany

BORSIG supplies synthesis gas boilers for gas pressures up to 350 bar (35,000 kPa) and steam pressures up to 160 bar (16,000 kPa). They are used in the synthesis gas loop of ammonia plants. The boilers are equipped with U-tubes and can be mounted both in the vertical as well as in the horizontal positions. With both designs, the steam drum can be integrated into the boiler if requested by the customer. At the same time, a feed water pre-heater can be installed in the boiler when required.

Request for a quote

BORSIG GMBH

Germany

BORSIG has developed its own boiler design. This boiler design is suitable for all gasification processes. The waste heat boiler is designed as a fire-tube boiler. The hot synthesis gas enters the heating surfaces with a temperature of about 1,400 °C and is cooled down in these tubes to approximately 300 °C. The heat from the synthesis gas is used for generating saturated steam.

Request for a quote

BORSIG GMBH

Germany

Transfer Line Exchangers (tunnelflow and linear quench coolers) from BORSIG are used in plants producing ethylene, an important starting material for plastics manufacturing. In these ethylene plants our transfer line exchangers are rapidly cooling down the so-called cracked gas in order to obtain the optimum yield of ethylene. BORSIG Transfer Line Exchangers are the result of more than 50 years experience and about 7,500 units have been supplied worldwide between 1965. BORSIG Process Heat Exchanger GmbH has developed two design types of quench coolers, reflecting the customer`s plant concept: 1. "Tunnelflow" transfer line exchangers (shell & tube design) 2. BORSIG "Linear" transfer line exchangers (double-pipe design)

Request for a quote

BORSIG GMBH

Germany

BORSIG has been producing scraped surface exchangers for more than 90 years. Modern design, orientated towards practical application, state-of-the-art manufacturing and testing methods and the staff‘s expertise add up to a high-quality scraped surface exchanger that fulfils all requirements in terms of stability, operating reliability and long service life. Scraped surface exchangers are supplied almost exclusively as compact units, so that installation work on site is reduced to a minimum.

Request for a quote

BORSIG GMBH

Germany

Today’s demand for increased efficiency and flexibility that comes along with higher temperatures, increased pressures and high cycling requires specific engineered valves. We design and manufacture high quality trunnion mounted ball valves tailored to your specific control processes by using customized control discs. Our control valve product line is engineered to suit very high differential pressure applications giving you an exceptionally high rangeability for your plant operation.

Request for a quote

BORSIG GMBH

Germany

In order to minimize downtime and to ensure maximum safety that calls for 100% system isolation, BORSIG offers bubble tight isolation and emergency shut-off valves that are tested to the limit to ensure performance and integrity even under the most challenging conditions. All of our isolation and emergency shut-off ball valves are coated application-specific for enhanced erosion and corrosion resistance to even withstand acids or caustics.

Request for a quote

BORSIG GMBH

Germany

BORSIG offers development, production and reconditioning of compressor parts, as well as their reconditioning and modification. Our product program comprises plate vales, ring valves, piston rod seals and oil scraper packings.

Request for a quote

BORSIG GMBH

Germany

BORSIG offers emission control membrane technology for terminals and refineries, marine loading and petrol stations. Our products are: BORSIG Vapour Recovery Units (VRU), BORSIG Aromatic Recovery Units, BORSIG Carbon Retrofit Units, BORSIG Marine Vapour Recovery Units, BORSIG Dock Safety Units, BORSIG Vent Recovery Units

Request for a quoteManufacturer/ Producer

Egellsstrasse 21

13507 Berlin - Germany