ENNOX BIOGAS TECHNOLOGY GMBH

Austria

Manufacturer/ Producer

ENNOX BIOGAS TECHNOLOGY GMBH

Austria

Biogas can contain large quantities of poisonous hydrogen sulphide depending upon the fermentation process and which input materials are used. This gas can cause permanent damage to gas engines or other consumers of the biogas. The majority of the hydrogen sulphide gas can be effectively removed by using an ennox active carbon filter ACF. In addition, the active carbon filter can be used for the removal of damaging siloxane from the biogas, furthermore for the neutralization of unpleasant odours in outgoing air and tanks.

ENNOX BIOGAS TECHNOLOGY GMBH

Austria

Condensation from saturated biogas collects at the lowest points in the pipework, in bends etc. This can negatively influence the effective operation of biogas systems. ennox condensate accumulator is installed at the lowest point in the pipework. The condensate gathers in the container where it can be discharged through a manual tap and/or an automatic siphon. As an option ennox will supply a level indicator or an automatic discharger.

ENNOX BIOGAS TECHNOLOGY GMBH

Austria

Fine sediment and foam particles in the saturated biogas originating directly from the digestion can make it s way into the pipework system. In order to eliminate sediment accumulation in the pipework an ennox sediment trap can be used. The trap is installed after the reactor directly in the pipework. With a special nozzle at the trap inlet the saturated and contaminated gas is set into a spiral motion. The particulate matter separates from the gas on the side walls and passed into the collection point with the extracted water vapour. Discharge is carried out with a siphon. Additionally a spray and control connection can also be installed.

ENNOX BIOGAS TECHNOLOGY GMBH

Austria

It is not our goal to simply sell our product to the customer. It is our goal to define the correct solution for our customer's individual application requirements and to offer support throughout the entire specification process with our technical competence, to give the customer all the information required in order to decide, with good conscience, for ennox. Our engineers have accumulated many years international experience and are true professionals in biogas technology. We are happy to offer our engineering expertise during design and specification right through to installation and after-sales support. Further to the implementation of the project we are also at your side! During the last decades the servicing of machines, systems and components has come more into focus. The quality of our customer service associated with the purchase of an ennox system is just as important for our customers as the performance or the price. We offer service or maintenance agreements for...

ENNOX BIOGAS TECHNOLOGY GMBH

Austria

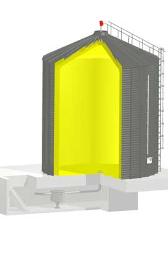

For temporary buffering due to fluctuations in gas production or inoperable production systems or consumers, a storage of the produced biogas is required. ennox has developed the NOXstore gas holding system for the zero pressure or fluctuating pressure storage of biogas from the digester. The storage of the biogas/sewage gas is made in a cylindrical gas bag which is freely hung in a building or silo. The silo serves in this case as an effective supporting and protective construction. The storage systems are designed according to the latest governing international standards and regulations i.e., DWGW, WAV, DWA, SUWA, safety regulations for biogas systems. The gas bag is manufactured from a high quality polyester membrane (non-flammable, fungus repellant and methane/UV resistant) utilizing the most modern frequency welding techniques. ennox offers not only the design, construction and installation of the gas storage system, but also the subsequent ongoing inspection and...

ENNOX BIOGAS TECHNOLOGY GMBH

Austria

For temporary buffering due to fluctuations in gas production or inoperable production systems or consumers a storage of the produced biogas is required. The holder is made up of two spherical shaped polymer membranes (other forms are also possible), lying one inside the other. The external membrane is maintained in a stable form with the use of an air blower. The external membrane then serves as protector for the inner membrane against the influence of environmental factors such as wind or snow. The biogas is contained within the inside polymer membrane. The pressure generated by the blower is transferred evenly over the inside membrane. This maintains a constant system pressure within the biogas reactor. Double membrane gasholders are available in various sizes, pressure classes and construction types. The design and specification of such systems is carried out according to the individual application requirements.

ENNOX BIOGAS TECHNOLOGY GMBH

Austria

Digesters and biogas reactors are normally designed and built to cover relatively low system pressures due to cost implications. In order to carry out effective cleaning of the system, operation of a consumer or transfer of the biogas, it is necessary to increase the operating pressure in the pipework. We supply our customers with radial ventilators for the increase of system pressure for biogas operations. Our radial ventilators offer distinct advantages over traditional systems for pressure increase and are punctuated by high reliability, operating flexibility, low maintenance and long life expectancy. The ventilators can be either directly driven or equipped with a belt drive. They are suitable for use in ATEX zone 1. Delivery is possible either as a single blower or skid-mounted as a complete blower station with piping, assembly and instrumentation.

ENNOX BIOGAS TECHNOLOGY GMBH

Austria

It is not our goal to simply sell our product to the customer. It is our goal to define the correct solution for our customer's individual application requirements and to offer support throughout the entire specification process with our technical competence, to give the customer all the information required in order to decide, with good conscience, for ennox. Our engineers have accumulated many years international experience and are true professionals in biogas technology. We are happy to offer our engineering expertise during design and specification right through to installation and after-sales support. Further to the implementation of the project we are also at your side! During the last decades the servicing of machines, systems and components has come more into focus. The quality of our customer service associated with the purchase of an ennox system is just as important for our customers as the performance or the price. We offer service or maintenance agreements for...

ENNOX BIOGAS TECHNOLOGY GMBH

Austria

THE robust and maintenance free flare suitable for small biogas systems, special installations or when an automatic gas flare is not specified. The ECO flare is manufactured entirely from stainless steel and equipped with high quality components (i.e., ATEX certified flashback prevention, DVGW certified manual flap...). Ignition of the electrode is carried out with the simple press of a button located in the control cabinet. The complete equipment for automatic operation is available for easy retrofit. An ignition system rated for 12VDC is available upon request.

ENNOX BIOGAS TECHNOLOGY GMBH

Austria

Our core business is the most up-to-date quality gas flare technology for a safe, efficient and environmentally friendly combustion of gases from landfill, bio and sewage gas systems. Our fully automatic flare NOXmatic with its extensive range of accessories can be suited for every low and medium temperature combustion application. With various burner systems we can cover the complete spectrum of power requirements in single or multi-stage operation. The NOXmatic flare is manufactured entirely from stainless steel and equipped with high quality components (i.e., ATEX certified flame arresters, DVGW certified automatic and manual valves...). All control and monitoring functions are achieved with an individual programmable controller, which also governs the signal transfer with the main controller. NOXmatic flares can be delivered worldwide with a capacity from 100kW to 20MW.

Manufacturer/ Producer

Neulandstrasse 36

6971 Hard - Austria