FRIEDR. FREEK GMBH - Electric Heating Elements

Germany

Manufacturer/ Producer

FRIEDR. FREEK GMBH

Germany

Polyester heaters also referred to as Polyester film heaters or Polyester foil heaters consist of an electrically conductive ink between two insulating respectively carrier layers of polyester. With a maximum size of 600 x 1000 mm, their average height is only 0.2 mm. As the picture examples show, practically any shape and type of cut-out is possible. Polyester foil heaters are resistant to permanent temperatures of up to 90°C (max. 100°C for short periods). It is generally not possible to predict which temperature a Polyester heating element will reach in the application, as there are extremely many influencing factors. These include not only the power, but also the mass and type of goods to be heated, the ambient temperature, air currents, the type of mounting and, of course, the control technology. Typical applications for Polyester heaters are e.g. cup warmers in coffee machines, mirror heaters, plate heat exchangers, flat applications with a target temperature below 90°C.

Request for a quote

FRIEDR. FREEK GMBH

Germany

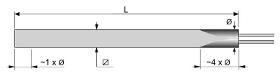

Occasionally also these terms are used for cartridge heates: heating cartridge, insertion heaters, spiral cartridge heaters. As a rule cartridge heaters consist of a cylindrical stainless steel tube and thus provide a high corrosion prevention. There is a heating wire inside which is wound onto a ceramic core. The number of coils varies depending on the power. In order to avoid a short-circuit, the cartridge heater is filled with magnesium oxide and compressed afterwards. Highly compacted they reach a surface watt density of up to 50 W/cm² and withstand highest stress. In the plastics industry cartridge heaters are used in hot runners in order to temper thermoplasts during injection moulding processes. Other areas of applications for process heat are e. g. packaging, diecasting or continuous casting in which zinc or aluminium are processed. Further applications are to be found in mechanical as well as medical and laboratory engineering.

Request for a quote

FRIEDR. FREEK GMBH

Germany

Square cartridge heaters are used where much power has to be installed near the surface of a tool, e.g. in cutting knives, sealing stations or hot plates. With a soft, malleable condition in stainless steel or nickel sheath square cartridge heaters can easily be pressed into common milled rectangular grooves. Apart from the advantageous heat transfer over ¾ of the sheath, it is not necessary to cement or cast in the heater which is imperative for round cartridge heaters. Unlike tubular heaters which are also available in square sections (see chapter Flexible Heating Pipes), the square cartridge heaters have the termination on one side and can be loaded with 16W/cm² (2.5W/in²) due to their special inside construction.

Request for a quote

FRIEDR. FREEK GMBH

Germany

Flexible silicone heaters are resistant to permanent temperatures up to 200°C, with self-adhesive foil 180°C should not be exceeded. Higher temperatures of 230°C are possible for a short time without destroying the heater. The temperature that will be reached within the application, generally is not easy to predict, as there are many influencing factors. In addition to the power, resp. surface load, this also includes mass and type of the material to be heated (thermal conductivity, surface quality, etc.) installation / assembly situation (bonded, vulcanised, clamped, etc.), ambient temperature, air movement and, of course, the control technology used. Application examples for silicone heater mats include: canteen kitchen technology / catering, anti-fog and anti-freeze applications, tool or plate heating in machines, 3D printers, laboratory equipment, composite materials repair, joint curing and much more.

Request for a quote

FRIEDR. FREEK GMBH

Germany

In general, a Kapton film heater is always more expensive than a silicone heater or polyester heater. Where chemical resistance or the weight of the flexible heating element plays an important role, however, Kapton heaters are the ideal solution. The resistance of Kapton Polyimide to fungi, bacteria, ozone, weather, ageing and most chemicals, acids and solvents is very good, so that heating elements made of Polyimide (Kapton) are an ideal solution for many critical applications. Kapton foil heaters are also silicone-free and are characterised by an even heat distribution. The dielectric strength of a Polyimide film is very high and so the flexible Kapton (Polyimide) heater can be very thin. Due to the small thickness, the heat transfer to the component is improved and higher surface loads are possible. Typical applications for Kapton film heaters are: Laboratory technology, aircraft electronics, printers, diagnostic instruments, vacuum chambers, medical equipment and many more.

Request for a quote

FRIEDR. FREEK GMBH

Germany

There are three main types of infrared emitters. They are classified according to emitted wave lengths. Which emitter type is the best for your application depends on many factors. For most applications an optimum match of emitted wave length and absorption of the target material is desirable. This means a highly efficient transfer of radiation energy in the material and thus a very quick heating. However, there are exceptions to the rule. At very high required energy densities, cyclical processes, transparent, thin or low-conductive materials it might be necessary under certain circumstances to deliberately use emitters whose characteristics deviate radically from the absorption characteristics of the material to be processed. Finally, in many applications, including thermoforming, all three basic emitter types are successfully used – long wave ceramic emitters, medium wave quartz emitters and short wave halogen emitters.

Request for a quote

FRIEDR. FREEK GMBH

Germany

The HSSD - Side Drum Heater is an easy and actual aid to the warming of steel barrels. It has got a higher efficiency than the Insulated Jacket HISD, but no thermal insulating function. For a very quick heating and higher temperatures up to three drum heaters can be used simultaneously for a 200-liter barrel. The Side Drum Heater is available in four standard sizes (25 / 50 / 105 / 200 liters) and can of course be made to measure, too. HSSD - Side Drum Heaters are suitable in particular to defrost frozen or other products, thus allowing to empty the barrels rapidly. Soaps, fats, varnishes and oily products can be melted as well, respectively reduced in their viscosity. In addition, the 200-liter element can be used in conjunction with the HBD Base Drum Heater to shorten the heating-up time further.

Request for a quote

FRIEDR. FREEK GMBH

Germany

The HISDpro - Side Drum Heater is a simple yet effective silicone insulated drum heater for the heating of barrels up to 90°C. The Silicone heating jacket is available in four standard sizes (25 / 50 / 105 / 200 liters) and can be manufactured to customer specifications as well. HISDpro heater jackets are particularly suited to melt soaps, fats, varnishes and oil-based products, or respectively reduce their viscosity. The 200-liter element can be combined with the HBD - base drum heater to reduce the heat-up time. These heater jackets are not only used on drums but also containers and any kind of glass-fibre reinforced plastics. They can be produced with any number of belts, e.g. to enable them to be clamped on to rotor blades.

Request for a quote

FRIEDR. FREEK GMBH

Germany

The HSHP – Drum Heater (220 °C) is suitable for steel drums (and with restrictions also for plastic drums). The outer material is a Teflon which is released for contact with food. The material possesses high levels of chemical and acid resistance. However, products such as waxes, soaps and materials with high water content can be heated excellently as well. The drum heating jacket is lightweight, robust and free of silicone. The excellent thermal transfer properties due to the perfect fit result in homogenous temperatures. Our silicone-free high-temperature drum heater is available in the standard size of 200 liters but can also be made to customer specification.

Request for a quote

FRIEDR. FREEK GMBH

Germany

The HTSD-High Temperature Drum Heater is our high temperature drum heater (220 °C) and exclusively suitable for steel drums. The heating jacket is used in areas where large surfaces need heating over 90 °C. This barrel heater is available in four standard sizes (25 / 50 / 105 / 200 liters) and can be manufactured to customer specifications as well. HISD heater jackets are particularly suited to melt soaps, fats, varnishes and oil-based products, or respectively reduce their viscosity. The 200-liter element can be combined with the HBD - base drum heater to reduce the heat-up time. The heating element of the HTSD heating jackets is sewn into a fleece made of silicone-insulated fibreglass material. The insulating outer housing consists of a binder-free mat made of textile glass. The heating element is therefore double insulated (protection class II). An optimal contact with the barrel, as well as a quick assembly and dismantling are achieved by the use of quick release buckles.

Request for a quoteManufacturer/ Producer

Sudetenstraße 9

58708 Menden - Germany