- europages

- >

- Measurement - Equipment & Instruments

- >

- FRIEDRICH VOLLMER FEINMESSGERÄTEBAU GMBH

FRIEDRICH VOLLMER FEINMESSGERÄTEBAU GMBH

Germany

Manufacturer/ Producer

Product catalogue preview

FRIEDRICH VOLLMER FEINMESSGERÄTEBAU GMBH

Germany

The radiometric gauges from Vollmer operate contact-free and measure from a safe distance. They are characterised by their extremely narrow design: With some systems the C-frame is only 120 mm wide. The X-ray systems from Vollmer have digital detectors which give them extremely low noise values. Vollmer supplies the systems with high-quality ceramic tubes and the necessary cooler. The isotope systems also have digital detectors. A particular feature of the Vollmer systems is that the radiation source is located in a special tungsten drawer that can be easily removed from the gauge. Alloy compensation is made either in the classic manner using calibration plates or alternatively at the computer according to the customer's chemical alloy analysis or simply with a small contact thickness gauge that measures the absolute thickness at the start of the pass and transmits this value to the radiometric thickness gauge.

Request for a quote

FRIEDRICH VOLLMER FEINMESSGERÄTEBAU GMBH

Germany

The gauges from the VSL Series measure the form, diameter, roundness and eccentricity of the rolls during the grinding process with very high precision. Form, radial run-out and eccentricity are measures with a precision of ± 1 µm. If an interface is available, they communicate online with the controller of the roll grinding machine and thus enable even more cost-effective use of the grinding machine. With the appropriate configuration, they measure the height and lateral alignment of the roll in the grinding machine before grinding, often enabling the set-up time to be significantly reduced. Vollmer produces the automatic roll measuring gauges for both bench-mounted machines where the roll is moved along the grinding wheel and for support machines where the grinding wheel is moved along the rotating roll. Vollmer supplies the systems for a broad spectrum of roll diameters.

Request for a quote

FRIEDRICH VOLLMER FEINMESSGERÄTEBAU GMBH

Germany

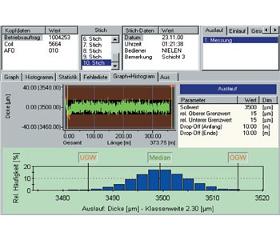

VGraph is the software package for the recording and visualisation of data with extensive statistical data evaluation options. It synchronously records up to 16 measurement values – for example thickness, width and speed of the strip, rolling force or strip tension – on a production line, stores them and evaluates them statistically. With statistical functions such as histograms, Cp and CpK values and error lists, VGraph provides valuable decision aids for the evaluation and further use of the coil produced. The diagnostic instruments allow optimisation of the rolling process and the line engineering. The optional FFT analysis detects periodic fluctuations in the strip thickness. VGraph meets the needs of day-to-day strip production. One example: Random lengths of strip at the leading and trailing ends (drop-off) can be suppressed – even subsequently – in the statistical evaluations.

Request for a quote

FRIEDRICH VOLLMER FEINMESSGERÄTEBAU GMBH

Germany

The BFI shapemeter rolls that we produce under licence from the VDEh-Betriebsforschungsinstitut (BFI) have a solid roll body with a homogeneous steel surface. They are normally installed instead of the existing deflector rolls. For the measurement of wedge-shaped strip, Vollmer offers a special solution that is also based on the BFI patent. It ensures that the flatness of the strips is measured correctly even though transversal stresses are created in the strip during coiling. Individual adaptation With individually manufactured diameters between 200 and 500 mm it is possible to precisely replace the deflector rolls in practically all mills. The outer surface of the roll body is absolutely homogeneous and can be reground on all standard roll grinding machines. The width of the measuring zones can be freely selected above 17 mm. The number of measuring zones that the roll should have is determined individually.

Request for a quoteVollmer: a synonym for precision measurement and control technology in the rolling process For decades now, the name Vollmer has stood for the highest precision and dependability in dimensional measurement in the rolling mill. Our work focuses on two parameters that are particularly important for the rolling of strips of steel, copper, aluminium and precious metals: thickness and shape. Vollmer is the world's only manufacturer able to offer the whole spectrum of measurement and control technology for cold rolling – from the single thickness gauge through to complete shape control and modernisation of rolling mills.

Website

Manufacturer/ Producer

Verbandsstraße 60 b

58093 Hagen - Germany

Company info

Key figures

-

- Company headcount

- 51 – 100

-

- Sales staff

- 11 – 50

Organisation

-

- Year established

- 1963

-

- Main activity

- Manufacturer/ Producer

Business info

Trading areas

- International

Payment methods

- Telex transfer

- Stand-by letter of credit

Delivery areas

Activities of FRIEDRICH VOLLMER FEINMESSGERÄTEBAU GMBH

- Measurement - Equipment & Instruments

europages also recommends

A selection of companies related to the activity:

A selection of products that might interest you

SHENZHEN PROMOSTAR HARDWARE CO.,LTD

Germany

These are the accssories use for machines.

Request for a quote

QUELLTECH GMBH

Germany

Laser Scanner Solution: This task is a typical application of the high-resolution QuellTech 2D/3D Q5-880 Blue Laser Scanners. Two of these units are placed at the left and at the right of the measuring objects, at a defined inclination angle. Blue laser light in this case is a prerequisite, as the cast parts are red-hot, hence emitting in the red spectral range. Additionally, the client was in need of a software solution for the project, so a 3D point cloud processing application was implemented, performing inline and evaluating width, height and angle results. QuellTech customer is able to inspect continuously the product quality, simultaneously avoiding scrap. He uses the same system for more than 10 different types of castings. Errors caused by manual inspection are considerably reduced, and safety for personnel is enhanced.

Request for a quote

QUELLTECH GMBH

Germany

The QuellTech laser sensor family Q4 or Q5 used for these tasks is generally mounted on an arm of a rotational axis, to scan along the complete 360° angle of the internal surface in a sequence of strips. The Q4 sensors can also be used to control the weld seam tracking itself for rapid setup and ease of use. Even during a project, the range and scope of the Q Series sensor demonstrates the advantages of a modular system to quickly adapt to project needs, where the smallest system has provided fast analysis of pipes as small as 105mm. The low power, with standard communication protocols, enable battery powered systems to transmit wireless data to other systems for review and cloud back up.

Request for a quote

KNIGHT OPTICAL (UK) LTD

United Kingdom

Knight Optical can offer you Plane Mirrors (general, λ/1 and λ/4), for use within 3D Mapping Applications in a range of materials such as Soda-lime float glass, white float glass, and BK7 glass. Plane mirrors also known as front surface mirrors or first surface mirrors are used within 3D Mapping Applications. As stock we hold a number of general purpose, λ/1 and λ/4 with a range of up to 6 types of coatings such as Enhanced Aluminium, Ali/SiO2 and Ali/Mgf2. Our general purpose grade mirrors are made from good quality float glass and generally available in thicknesses of 1mm, 3mm and 6mm as standard. How our mirrors are used within 3D Mapping, is they are used as a sender and receiver of a laser beam that will take a reading of a specific surface, and from that reading it can create a 3D map of the surface that is has read. FOR MORE INFORMATION READ THE PDF..

Request for a quoteRequest for quotes

Create one request and get multiple quotes form verified suppliers.

- Only relevant suppliers

- Data privacy compliant

- 100% free