- europages

- >

- Forming- rubber - machinery

- >

- SIEMPELKAMP MASCHINENFABRIK GMBH

- >

- Individual „Direct Tensioning“ Concept With Controlled Steel Cord Tension

Individual „Direct Tensioning“ Concept With Controlled Steel Cord Tension

Description

Siempelkamp’s steel-cord conveyor belt presses distinguish by an innovative steel-cord tensioning concept: the controlled steel-cord tension distribution system increases production safety and improves product quality. The electromotive tensioning system, which is individually controlled and installed directly in the creel with integrated measuring and control functions, allows a 100%-control over the actual steel-cord tension distribution. The exact quality reporting enables our customers to optimize the production, hence the product’s quality. The new concept replaces the xed-nger comb used in previous systems with a roller comb. The friction between comb and steel cables is thus eliminated. Consequently, the abrasive wear on the galvanized steel cables is reduced. Unlike the traditional concept, the new roller comb prevents any variations in tension distribution. Services Direct tensioning control in the creel Individually controlled steel-cord tension distribution

- Forming, rubber - machinery

- Siempelkamp

- Rubber Siempelkamp

- Siempelkamp Press-Systems

Similar products

QUELLTECH GMBH

Germany

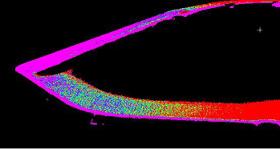

Particular Challenges: The seal surfaces in this case are made of very glossy metal, with the drawback of emitted reflections. This effect during an optical measurement must be eliminated. Furthermore, it is absolutely necessary to guide the laser scanner on a linear path over the surface, since fluctuations of distance may falsify the measurement result. QuellTech Solution: The Quelltech model Q5 disposes of an adequate resolution in X and Z direction and proves to be able to verify the planarity tolerances and to measure the size of defects. Meanwhile a precise rotary axle, used as guiding element, moves the scanner over the surface to be evaluated. Interfering artefacts caused by the glossy finish are suppressed by particular algorithms integrated within the software. As an encoder value is permanently supplied by the rotary axle, the position of each scanner profile within the point cloud can accurately be determined.

Request for a quote

JUNTA POLYMERS

Belgium

Junta Polymers offers you a wide range of rubber molded parts. Our specialized machines for compression or injection can produce every possible shape in VMQ (silicone), EPDM, NBR, CR, FKM or SBR rubber molded parts.

Request for a quoteRequest for quotes

Create one request and get multiple quotes form verified suppliers.

- Only relevant suppliers

- Data privacy compliant

- 100% free