- europages

- >

- Piston pumps

- >

- JERKO-SPRÜHSYSTEME GMBH

- >

- products

JERKO-SPRÜHSYSTEME GMBH

Germany

Manufacturer/ Producer

JERKO-SPRÜHSYSTEME GMBH

Germany

Secial spray nozzle for forging lubricants and casting lubricants. Maintenance free and large-sized to reduce the risk of clogging. The special feature of the EJ86 nozzel familiy is that the spray angle at the nozzle head can be varied by simply adjusting the nozzle head. Due to these variations, this spray head is suitable for many applications.

Request for a quote

JERKO-SPRÜHSYSTEME GMBH

Germany

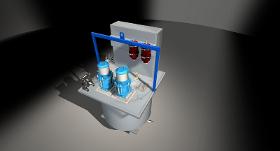

Our supply tanks are suitable for all common lubricants. No matter if graphite containing, salty or oil based products, the Jerko spraying unit is equipped for all applications. Standard sizes form 250 litres up to 2.000litres Due to the special surface and well thought-out cleaning function, the unit is durable and requires low maintenance. For cleaning, the complete cover can be lifted off with a few simple movements. This modular system allows easy replacement of the components. The necessary pressure to supply the spray equipment is generated by a piston pump developed by Jerko with a transmission ratio of 1:3.

Request for a quote

JERKO-SPRÜHSYSTEME GMBH

Germany

Dosing systems for all common lubricants. With the Jerko concentration calculator you get always the right mixture no matter what density the medium has. The dosing systems are available as stand alone solutions or as an optimal addition to our systems or existing spraying system.

Request for a quote

JERKO-SPRÜHSYSTEME GMBH

Germany

Jerko preparation systems are specially adapted to the requirements of forging and die casting lubricants Efficient cleaning of water-soluble lubricants. The preparation of dispersions or suspensions is also possible. AND Reduce disposal costs by cleaning process water. The treatment plant is the economically optimal supplement to our efficient spraying systems. With a Jerko treatment plant you can save up to 80% of lubricant and disposal costs. In many cases the ROI is less than one year! Score points with new, innovative solutions at your next environmental audit! From manual to fully automatic reprocessing, Jerko develops the right solution together with you.

Request for a quote

JERKO-SPRÜHSYSTEME GMBH

Germany

The modular manual spray lances were developed for simple spraying requirements in the forging and die-casting industry. Compact design, easy to handle and with the 2-step trigger ideal for spraying and dry blowing The large selection of spray lances and nozzles allows an optimal adjustment of the spray mist for your requirements. Due to the robust design of our manual spray lances, continuous operation over years is no problem.

Request for a quote

JERKO-SPRÜHSYSTEME GMBH

Germany

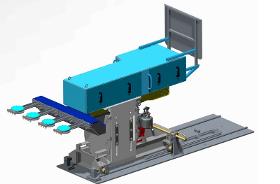

Jerko High Speed Manipulators are designed for extremely rough environmental conditions. Due to their encapsulated design, the ingress of dirt is impossible, while at the same time high loads up to 300kg can be handled. Driven by a powerful servo motor and a low-maintenance toothed belt drive, extreme accelerations up to 15m/s² are possible. Due to this simple and ingenious design, the manipulator can be integrated in all forging lines. Different spraying tools are possible to meet every task The manipulators can be modularly equipped with several independent axes. This design saves money and increases the productivity of your forging line! Many optional extras can be configured to meet all requirements.

Request for a quote

JERKO-SPRÜHSYSTEME GMBH

Germany

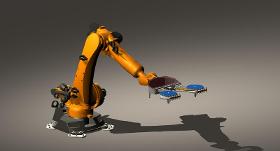

Jerko spraying robots offer the greatest possible flexibility. Freely configurable movements, coupled with proportional volume control during movement, ensure an efficient spraying process. Even hard-to-reach areas can be sprayed with the robot and our unique spray heads. Equipped with state-of-the-art communication and all safety features, the robot is ideal for addition to existing forging lines. The complicated programming puts you off? With the user interface developed by Jerko it is possible to learn the programming within a few hours. The motion sequences are programmed by means of simple touch buttons and speed input. The intelligent Jerko control takes care of the rest. Extensive and cost-intensive training or programming work is a thing of the past!

Request for a quote

JERKO-SPRÜHSYSTEME GMBH

Germany

The "hand spraying robot" with EJ86 spray head was developed to provide a uniform and reproducible spray pattern in the forging process. It is based on a KUKA robot of the 20 kg class with a specially developed, simplified user interface! With this operating concept, available exclusively from Jerko, time-consuming and expensive robot training at the manufacturer is a thing of the past. Equipped with all necessary interfaces, the robot can be "safely" integrated into new or existing forging lines. Each robot has "Safe Operation" to spray safely even on manually operated presses.

Request for a quote

JERKO-SPRÜHSYSTEME GMBH

Germany

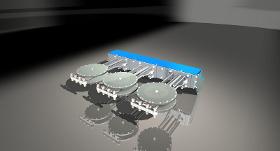

Unique plate spray heads adapted exactly to your requirements and geometries. Thanks to a design developed by Jerko, the spray heads produce a uniform and powerful spray pattern with ideal atomisation and high impact speed. Optimal cooling of the tools in the shortest time! Our plate spray heads enable the fastest spraying times of all spraying systems available on the market! Jerko plate spray systems are also characterised by a robust and simple construction. Blockages, costly repairs or the adjustment of calottes are a thing of the past. The modular design allows for a wide variety of geometries by simply changing the spray or carrier plates. Expensive special spray heads, nozzle attachments or obsolete calotte spray heads are no longer necessary

Request for a quote

JERKO-SPRÜHSYSTEME GMBH

Germany

Our newly developed spray rings enable an exact spray pattern over the entire diameter. The system allows switching between cooling and lubricating in a few milliseconds with a constant spray pattern. The design developed by Jerko creates an even and powerful spray pattern with ideal atomisation and high impact speed. Optimal cooling of the tools/mandrels in the shortest time! Jerko spray rings are also characterised by a robust and simple construction. Clogging, costly repairs or adjustment work are a thing of the past. The modular design allows all diameters or even individual areas to be cooled by special nozzles.

Request for a quoteManufacturer/ Producer

Hooghe Weg 31

47906 Kempen - Germany

europages also recommends

A selection of companies related to the activity:

A selection of products that might interest you

WILHELM KELLER GMBH & CO. KG

Germany

Ultra-compact and quiet pump series with low self-heating for run times up to 100% ED. The pump is self-priming up to approx. 6 meters.

Request for a quote

BÜRKLE GMBH

Germany

PumpMaster, canister and barrel pump for petrochemical liquids. The manual pressure pump is ideally suited for drawing off, decanting and emptying canisters and barrels. The hand pump is used to create excess pressure that forces the liquid out of the container. The stopcock also allows extraction of small quantities of liquid. The PumpMaster container pump is mounted on the container using a flexible stopper with a variable and adjustable diameter. No special thread adapters are required. PumpMaster fits all commercial container openings with a diameter from 46.5 mm to 60 mm. The immersion tube has a length of 95 cm and it can be shortened depending on the size of the container.

Request for a quote

KAMAT GMBH & CO. KG

Germany

customer-specific unit design incl. powerful high-pressure pump easy maintenance cavitation-free central drainage according to the latest global emission laws optionally fully automatic control own software with best support optional extreme sound absorption optionally all explosion protection classes

Request for a quoteRequest for quotes

Create one request and get multiple quotes form verified suppliers.

- Only relevant suppliers

- Data privacy compliant

- 100% free