- europages

- >

- Electroheat - machines and equipment

- >

- FRIEDR. FREEK GMBH

- >

- Nozzle Heaters with Housing

Nozzle Heaters with Housing

Energy efficient nozzle heaters for high-cavity PET hotrunners

Description

The Freek-MicroCoil 1.3 x 2.3 mm used in the "Brazed-Together" energy-saving nozzle heater is wound tightly onto a precision tube with good thermal conductivity and encapsulated and thermally insulated by means of an outer housing. For even more reliable heat transfer, the heater can optionally be vacuum brazed. The "Brazed Together" design combines many advantages: high accuracy, good heat conduction, high power density, mechanical stability and, last but not least, up to 20% higher energy efficiency. Freek is one of the technology leaders in the field of hot runner heating and supplies the who's who of the industry. Energy efficiency is one, if not the central innovation topic here. Manufacturers of high-cavity PET hotrunners and moulds in particular benefit from the BT nozzle heaters, and in several ways: because the less energy that is put into the system, the less energy has to be taken out on the cold side, the mould. This saves even more energy and shortens the cycle time.

- Electroheat - machines and equipment

- nozzle heaters

Product characteristics

- Heater

- MicroCoil 1,3 x 2,3 mm

- Standard Dimensions Ø 19,05

- Ø 19,05 x 25,40 (30,50) mm [Ø 3/4" x 1 (1,2)"]

- Standard Dimension Ø 22,40

- Ø 22,40 x 30,50 (34,00) mm

Similar products from FRIEDR. FREEK GMBH

FRIEDR. FREEK GMBH

Germany

The Freek heat transfer nozzle heating system especially addresses manufacturers and users who operated their hotrunner nozzles with cast-in heaters in the past and would like to stick to their engineering know-how without paying the high price of this former heater design. The standard material of our Freek heat transfer nozzle heater alternative is brass, with or without coating, preferably with a slit. The slit allows the assembly of an external bendable thermocouple and facilitates the disassembly, e.g. in case of a revision and can be coiled over. This is not possible at competitor's nozzle heater solutions. Freek's tight coiling at the heater's ends provides a maximum possible power concentration (patented).

Request for a quote

FRIEDR. FREEK GMBH

Germany

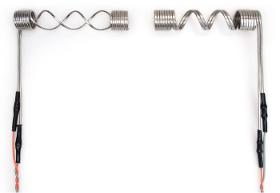

Owing to their small cross-sectional dimensions, MicroCoils are most often connected at both ends and do not permit the addition of a thermocouple. We prefer to use nickel as the sheath material here because it combines the best thermal conduction properties, high corrosion resistance and excellent deformation properties. To ensure that the standard 1000 mm PTFE-insulated connection cable can be positioned at one end, despite the standard two-ended connection of the element, in most cases the MicroCoil is formed into a hairpin shape and wound/laid in a bifilar (parallel) format. Our unformed MicroCoils are also supplied in the hairpin bend shape as standard.

Request for a quote

FRIEDR. FREEK GMBH

Germany

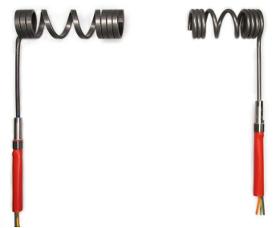

HotCoils have a larger cross-sectional area and are thus capable of greater power than MicroCoils. For this reason they are used in hot runners with adequate space and where high heat densities are required. Owing to the large number of variants and for cost reasons, the sheath material for HotCoils is stainless steel - the standard for the market and thus also for Freek. HotCoils are large enough that thermocouples can be integrated into them. Our standard here is Type J (Fe-CuNi; red/blue), while Types J and K are also available conforming to the IEC and ANSI standards (see colour codes). Since the measurement point of a built-in temperature sensor is situated in the heater and never where the heat is actually required, a HotCoil with a thermocouple makes particular sense where the application allows the use of larger processing (temperature) windows or where the installation location or the design requires protection against overheating.

Request for a quote

FRIEDR. FREEK GMBH

Germany

Characteristics of our HotMicroCoils with reflection tube are easy mounting and variable heat distribution. Because of its direct touch and toleranced fit, the sleeve coil heater allows a very good heat transmission to the nozzle. In all our HotMicroCoil heaters with reflection sleeve the assembly of a thermocouple is possible and recommended for bigger diameters and power.

Request for a quote