SERVOLIFT GMBH

Germany

Manufacturer/ Producer

SERVOLIFT GMBH

Germany

Manual weighing by Servolift, either connected to a lifting function or for vertical product flows, is highly flexible and easy to handle due to modular construction. The weighing system, the size of the weighing funnel, the lifting system, etc. are all specially adapted to customer specific requirements in a trouble-free way. Technical description A large load range Exchangeable weighing funnels with various volumes Dust exhaust can be integrated Operating sequences from simple and manual to fully-automated systems Various control designs, such as simple weighing to recipe-guided systems connected to an ERP system. Low-dust design up to high-containment solutions

Request for a quote

SERVOLIFT GMBH

Germany

Frequently in pharmaceutical environments, one must often separate the source package from the target package. This and many other challenges to secure, traceable and ergonomic weighing are ensured by Servolift weighing systems. Also a multiplicity of versions ensure that containers of various shapes and sizes can be used. The flow properties of individual products are considered through the use of many different dosing solutions. One can design a system for small target packages, such as drums from 10 L to 200 L up to large product containers. The level of automation and data interfaces are determined in accordance with the project, developed with customers, and implemented at our facilities. Technical description Loading station for the source package: Very different packages possible: Big-Bag, silos, containers, bag discharge stations, pre-weighed small packages Automatic, dust-free docking stations Automatically or manually-controlled discharging aids Product scanning using...

Request for a quote

SERVOLIFT GMBH

Germany

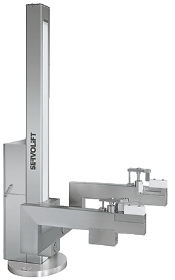

Lifting, transporting and tilting drums and bins is a typical task especially in the chemical and pharmaceutical industrie as well as in food manufacture. SERVOLIFT, the original handling system, has been manufactured for approximately 30 years. It provides decisive advantages thanks to its two arms: unhindered view of the transport materials, exact and safe operation, uncompromising compliance with all hygiene requirements as well as a higher degree of reliability and cost effectiveness. Strong, maneuverable and easy to operate: the new SL 250 Technical description Free view of the carried load Loads up to 350 kg Explosion protection for zones 1/21 and 2/22 Lift up to 4,250 mm GMP-compliant construction, easy to clean and completely manufactured of stainless steel Faster and easier exchange of the gripper system for various drum types Space-saving due to its very compact design Very maneuverable in confined spaces Can be used everywhere due to its low weight Extendable versions...

Request for a quote

SERVOLIFT GMBH

Germany

Working with and handling drums is done all the time in the pharmaceutical, chemical and food industries. That is why efficient drum handling is a must, and needed in order to optimally structure operational processes. Our products help you with this and offer you a variety of opportunities. Efficient drum handling for drums of any diameter and material Technical description Stainless steel or cGMP-compliant designs High flexibility, such as for drums with any dimensions and of any design No load limitation Tilting function: lengthwise or cross-wise to the column Stationary or mobile designs Floor/ceiling-mounted, free-standing or ceiling-positioned designs Electro-hydraulical or electro-mechanical solutions Extensive series of control designs, from simple direct manual lever controls up to PLC-controlled sequences Various take-up and clamping systems such as a manual clamping ring, motor-driven clamp system, squeeze funnel clamp, fork shaped spears, special designs depending...

Request for a quote

SERVOLIFT GMBH

Germany

Bin lifters from SERVOLIFT are adapted to your bin types. Its modular construction provides for functional extensions by combining special installed components and process machines. One can develop an optimal, ergonomic system solution when using the bin lifters in combination with Servolift containers. Universal handling of all bin types Technical description Stainless steel - or cGMP-compliant designs High flexibility, such as for containers of any dimension and design High load range Stationary or mobile design Floor/ceiling-installed, free-standing or ceiling-positioned designs Electro-hydraulical or electro-mechanical solutions Wide range of control designs, from simple, direct manual lever controls up to PLC-controlled sequences Integration of product controls, such as installation of dosing units Pick up of containers, including discharge aid and valve actuators Extensive take-up and clamp systems, container holding device, fork shaped spears, special designs depending...

Request for a quote

SERVOLIFT GMBH

Germany

These types of machines are used for a variety of applications when combined with process machines. The use of cone mills, hammer mills, vibration sieves, sifters, mobile for various areas or stationary. The broad applications spectrum of these devices can be seen in weighing for raw materials preparation or granulation for calibration, to name two examples. The take-up system is designed and adapted depending upon the process machines and the specified runs. Take-up of various additional devices Technical description cGMP-compliant design Mobile or stationary or combinable for high flexibility Adapted take-up system, depending upon the process machines Variable, adjustable lifting function - for mobile units with telescoping designs for low drive-through heights Function extensions through the integration of tilting and pivoting functions Various containment designs, such as low-dust connections up to high-containment solutions Extensive control designs, depending upon...

Request for a quote

SERVOLIFT GMBH

Germany

Storage, production and operating levels are often linked in a vertical fashion for smooth material flow. A SERVOLIFTt platform lifter is a sensible solution to an elevator. Space-saving, and able to execute the platform with various accesses helps to solve space problems in material flow. A closed hoistway is not needed. Platform lifters for simple material or passengers transport, mobile or stationary. Technical description Access to the platform in the lower floor: Additional ramps Ramp to the carrying arm Trench under the carrying arm for even loading Platform with even surfaces as a transport footprint including a railing with a single door Column behind the access point Column lateral to the access point 2 access points Application: Installation in hoistway (as a material elevator) Lifting containers (such as drums, bags) to feed a system Lifting liquid containers for gravimetric emptying

Request for a quote

SERVOLIFT GMBH

Germany

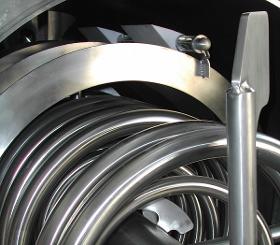

A system is only complete when they also fulfill product transfer to interfaces. Thus the specified OEB level is supplied from SERVOLIFT with valves, split valve systems, feed systems, funnels, discharging aids, filling and discharge tubes, etc., corresponding to the containers and handling equipment. The solutions meet the requirements of cGMP and the FDA. Whether protecting the products against their environment, or protecting employees from the product, SERVOLIFT always has the solution, with over 40 years’ experience in the field. Low-dust or dust-free Technical description DECELERATOR: Product transfer from one process to another are often vertical in the pharmaceutical and chemical industry. The feed must then be carried out for the most part over a given vertical distance. Controlled product flow using regulated compressed air transfers the product without segregation at the adapted fall speed in vertical product transfer systems. Segregation-free, controlled product...

Request for a quote

SERVOLIFT GMBH

Germany

SERVOLIFT has developed a variety of special solutions due to the many customer-specific requirements. Whether it’s a fully automated, ceiling-guided feed system, a handling system for various bin shapes or an emptying system for pasty products (following plates with pump stations) - Servolift always has the right solution for customer-specific tasks. Custom development for your tasks

Request for a quote

SERVOLIFT GMBH

Germany

SERVOLIFT container blenders are specially designed for gentle product blending and flexible pick up of various containers. The hydraulic clamping system ensures absolutely secure take-up of the blending container. The PLC and recipe-controlled blending process provides optimal adaptation to the blended goods. The Servolift horizontal clamp bar system easily picks up various container sizes or adapters for drums and small containers. The ability to extend the handling functions of lifting, lowering, inverting, pivoting the blender columns provides many applications for the container blender. This is extended through optional installed and auxiliary systems such as automatic feed and unloading, chopping in the blending container, spray system to add liquids to the blended product, prior and follow-on weighing machinery, dosed unloading, NIR systems, etc.. Blend in a closed system Technical description Stainless steel or cGMP-compliant design Take up blending containers which are...

Request for a quoteeuropages also recommends

A selection of companies related to the activity:

A selection of products that might interest you

KASAG SWISS AG

Switzerland

In order to prepare the fruit base, vegetables, jam, marmalade, jelly and sauces, horizontal or vertical mixing systems are used. Mixers are vital for attaining the highest product quality. The main aim is to ensure consistent mixing and temperature distribution by applying the lowest possible shear force on the pieces of the product. Since it is possible to thereby realise short process times along with the qualitatively high-value process apparatuses, KASAG has the ideal mixing technology for you. For the horizontal mixers, KASAG also has a special bearing and mechanical seal that has been tried and tested over many years. On an ongoing process to develop our mixing system and the bearing and mechanical seals further to attain optimal product quality and to enable smooth operation.

Request for a quote

BASE GROUP SP Z O.O.

Poland

We have been manufacturing stainless steel machines and feeders constructions for food industry. The stainless steel structures are welded of different sizes and weight. Stainless steel feeders and mixers are among our currently manufactured products. We manufacture high quality steel constructions for food industry, which are customized to our customers’ individual needs and in accordance with the standards ISO-3834-2 and others international standards.

Request for a quote

GEBRÜDER LÖDIGE MASCHINENBAU GMBH

Germany

The continuous ploughshare mixer uses the mixing and fluid process introduced to mixing technology by Lödige. The ploughshare shovels in special arrangement on a mixing shaft in a horizontal, cylindrical drum rotate. Their peripheral speed and geometric form are coordinated in such a way that the mix is moved out of the product bed against the centrifugal force and in axial direction at the same time. The mixing elements having a defined shape and a special arrangement on the shaft, they ensure not only a reliable product conveyance but also a sufficient back-mixing of the product. All the product is constantly involved in the process, ensures a maximum mixing intensity at even the highest throughputs and shortest residence times until the product is discharged out of the mixer via an outlet. The continuous process can be run at filling levels between 20 % and 50 % without influencing the mixing quality. Choppers can be additionally installed in the mixing drum.

Request for a quote

GEBRÜDER LÖDIGE MASCHINENBAU GMBH

Germany

The application range includes everything from processing of viscous components to paste-like products with poor flow. The range of food applications is exceptionally broad and there are also various applications for the pharmaceutical industry. The conical shape permits thorough residue-free discharge. The wet mixer system is a vertical mixing system for batch processes. The geometry of the conical or cylindrical mixing vessel, the arrangement and shape of the tools and their peripheral speed are adapted to each other in all sizes, resulting in effective mixing of all components. Depending on the process engineering tasks, the individual mixing tools are combined to form one tool both for material transport and for dispersion and disagglomeration processes. The installation height in the vessel is adjustable within a wide range. An adjustable deflector can be used to affect the product movement in a systematic fashion.

Request for a quoteRequest for quotes

Create one request and get multiple quotes form verified suppliers.

- Only relevant suppliers

- Data privacy compliant

- 100% free