- europages

- >

- KB ROLLER TECH KOPIERWALZEN GMBH

- >

- Seamless Polyimide Fuser Belts

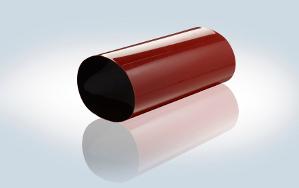

Seamless Polyimide Fuser Belts

Description

For a few years now seamless polyimide belts have been used in toner fusing for desktop printers and multifunctional printers. The most important advantages compared to using traditional steel or aluminum cores are: significantly shorter times lead to reach run temperatures major improvements in energy efficiency weight-saving and lower logistic costs flexible belts enable higher print speed and resolutions by allowing a wider fusing nip for both b&w and color applications For these applications KB RollerTech developed a special coating process and produces seamless belts under clean room conditions. Different thermal and electrical properties of these belts can be precisely adjusted by adding special fillers. Today, the following dimensions are possible: Diameter: 20 - 310 mm Length: < 700 mm Wall thickness: 25 - 150 µm For the subsequent coating with anti-adhesive materials two alternative processes are used: Spray coatings with fluoro-polymers and subsequent sintering Coat

Request for quotes

Create one request and get multiple quotes form verified suppliers.

- Only relevant suppliers

- Data privacy compliant

- 100% free