- europages

- >

- Surface inspection systems

- >

- NEXTSENSE GMBH

- >

- Surface Inspection & Profile Measurement System OSIRIS

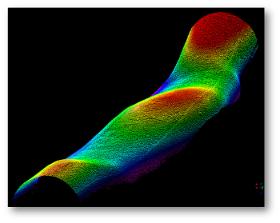

Surface Inspection & Profile Measurement System OSIRIS

Inline measurement of surface defects and dimensional accuracy of long products

Description

OSIRIS is a stationary, optical measuring system for inline control of dimensional accuracy and surface quality of long products. With state-of-the-art laser light cutting technology and high scanning rates, the OSIRIS systems offer a complete 3D reconstruction of the product. With the OSIRIS Hot version, up to 1,100 degrees hot long products can be analyzed. The measurement results are displayed in real time on the control terminal and thus allow early corrective action to increase throughput and product quality. The surface inspection function automatically detects and classifies deviations in the product surface (peeling, blow-outs, scoring, rolling etc.). In addition, profile cuts of the long product are simultaneously generated to check length dimensions such as width and height, various radii and angles. Different system sizes allow the measurement of large and small long goods.

- Surface inspection systems

- Surface Inspection

- Surface Defects

- Inline

Product characteristics

- Technology

- Laser light section

- Function

- Surface Inspection & Profile Measurement

- Versions

- OSIRIS Hot / OSIRIS Cold

Documents

Videos

Similar products

QUELLTECH GMBH

Germany

Particular Challenges: In the course of the production, endless cables are running at a considerable speed, and supervision has to be carried out nearly under real-time conditions. The size of the objects to be determined, i.e. of the flaws to be discovered, is in the range of only some hundredths of a mm. Another difficulty is the fact that surfaces with very different reflectivity and roughness are involved. In order to be able to check the cables all around, several laser scanners must be in place, mounted at different angles, thus covering the entire range of 360°. Quelltech Solution: The solution consists in a configuration of four Q6 laser scanners, mutually displaced by 90°, so the entire surface of the cables is in the field of view. On the basis of the 100% inline inspection, the position of defects can precisely be determined, without losing too much time.

Request for a quote

OPTIGRÜN INTERNATIONAL AG

Germany

Optigrun Inspection Chamber TAR 250 to keep roof drainage outlets free with four connection options for TAR 80/250 or TAR 120/250.For pressure drainage and keeping drainage outlets free 4 possible connections for the drainage gutter TAR 80/250 or TAR 120/250 (preperforated openings) Chamber walls and lid with entry seals With aluminium chequered plate Walkable

Request for a quote

KNIGHT OPTICAL (UK) LTD

United Kingdom

Knight Optical can offer you Stock and Custom Colour Glass Filters, for use within Inline Cameras in a range of materials of brands such as Schott, Kopp and CDGM. Depending on the achievable wavelength and desired affect you need for the Inline Camera we can find a suitable material for your application. Colour Glass Filters are good for selecting a particular wavelength to be absorbed so that the high out of band blocking in achieved. With regards to the use in Inline Cameras, Colour Glass Short pass Filters are more desirable as they cut out the IR wavelengths mean the imaging is not saturated with the IR giving the image better clarity. Colour Glass Filters are polished sheets of special glass that have been cast with a dye. Colour Glass Filters generally are relatively cheap and very stable. The disadvantage with them is that they are only available in a relatively small number of variants, and so can be restrictive in shortwave selection. Read PDF for more Information….

Request for a quote

SHANGHAI NPACK AUTOMATION EQUIPMENT CO., LTD.

China

The inline piston liquid filling machine is more flexiable, and suitable for a wide range of container size range from 100ml to 5000ml.It is has advantage of high filling speed, high accuracy and easy adjustment for different types of containers. It is application for any viscous liquid to thin liquid which is non corrosive the stanless steel, Piston filling machines are commonly used in industries such as food and beverage, pharmaceuticals, and cosmetics, where precise and consistent dosing is important. They can handle a wide range of products with varying viscosities, from thin liquids to pastes and creams.

Request for a quoteRequest for quotes

Create one request and get multiple quotes form verified suppliers.

- Only relevant suppliers

- Data privacy compliant

- 100% free