- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- finished metal products

Results for

Finished metal products - Import export

NOVELTY STEEL

Turkey

Decorative metal panels have emerged as a prominent feature in modern architecture and housing projects. Laser-cut metal panels are architectural elements crafted using CNC laser cutting technology.

Request for a quote

ESTIMET SP Z O.O.

Poland

Bøying av plater på numerisk styrte kantpresser, opptil knekkelinjens lengde (bøyingslenge) 5000mm

Request for a quote

PLANSEE SE

Austria

Spare parts include for example chambers, filaments, arc slits, holders and many other parts. The pare parts are made of graphite, molybdenum, tungsten and alloys. They are extremely durable and long lasting and therefore save money and maintenance time. 100 or more Plansee components are at work in every beam path. They ensure that the ions are generated efficiently and guided precisely and free from impurities along the beam path to the wafer. For customers in the semiconductor industry, Plansee spare parts are increasingly becoming more than just spares. Taking the equipment manufacturer's original spare parts as starting point, Plansee optimizes the geometries and material compositions. The benefits to you: — Simplified component installation and removal — Longer service lives — Lower cleaning costs — Reduced maintenance work — Reduced downtimes

Request for a quote

ORGECO SPOL. S R.O.

Slovakia

As experts in metal fabrication, we specialize in crafting custom brackets and consoles for a multitude of purposes, precisely tailored to our clients' specifications. Our advanced manufacturing facility employs cutting-edge technologies such as laser cutting, CNC sheet metal bending, robotic welding, and robotic grinding to ensure the highest quality and precision in every bracket and console we produce. Whether fabricated from steel, stainless steel, or aluminum, our brackets and consoles are engineered to meet stringent standards of durability and performance. Additionally, we offer a variety of surface finishes including powder coating, anodizing, plating, hot dip, and KTL, providing both protection and aesthetic appeal. At every stage of the fabrication process, from design to finishing touches, we uphold a commitment to excellence, delivering reliable and resilient brackets and consoles that exceed expectations.

Request for a quote

ORGECO SPOL. S R.O.

Slovakia

We specialize in manufacturing precise sheet metal components according to customer drawings and specifications, whether in steel, stainless steel, or aluminum. Our commitment to precision is ensured through the use of ACB sensors equipped in our bending and forming machines, allowing us to achieve highly efficient production repeatability. Additionally, we utilize 4 press brakes from TRUMPF company - models 7036, 3066, 5170, and 5085 - which enable us to bend sheets with a maximum width of 4250 mm. However, considering laser cutting capabilities, we bend sheets with a maximum width of 4000 mm, ensuring seamless integration of all production processes.

Request for a quote

ORGECO SPOL. S R.O.

Slovakia

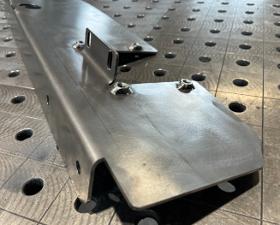

We specialize in producing compact liquid tanks for machinery, ensuring top-quality performance. These tanks undergo rigorous 100% testing to guarantee their tightness. Crafted from sheet metal, our tanks are manufactured using cutting-edge technologies such as laser cutting, sheet metal bending, robotic welding, and robotic grinding. These modern techniques ensure precision and durability in every tank we produce. With our commitment to excellence and advanced manufacturing processes, we deliver reliable liquid containment solutions tailored to the needs of our customers and their machinery. Our dedication to quality control means that every tank leaving our facility meets the highest standards of performance and reliability, providing peace of mind to our customers. Trust in our expertise and innovative approach to manufacturing, ensuring that your machinery is equipped with the finest liquid containment solutions available on the market.

Request for a quote

ORGECO SPOL. S R.O.

Slovakia

At our facility, we utilize state-of-the-art laser cutting technology to ensure precision and efficiency in our manufacturing processes. We operate two cutting-edge laser cutting centers equipped with 3kW and 6kW fiber sources, respectively. Our 3kW laser center offers a maximum working dimension of 2000x4000mm, while our 6kW laser center boasts working dimensions of 1500x3000mm. These capabilities allow us to handle a wide range of project sizes with ease and accuracy. When it comes to material thickness, our laser cutting centers excel. We can effortlessly cut through steel up to 25mm thick, stainless steel up to 20mm thick, and aluminum up to 15mm thick. This versatility enables us to accommodate various project requirements and deliver precise results every time. With our cutting-edge laser technology and skilled team, we ensure that every component we produce meets the highest standards of quality and precision, meeting the diverse needs of our customers across industries.

Request for a quote

ORGECO SPOL. S R.O.

Slovakia

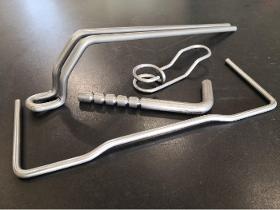

We are specialized manufacturers of wire products tailored to the requirements of our customers. We operate two modern CNC 3D wire bending centers with the following parameters: CNC bending wire center Numalliance 310 OPT Machine parameters: Max. wire tensile strength: up to 600 N/mm² or 85 Ksi Wire diameter: From 2.5 to 10 mm 3D CNC bending wire center Numalliance 214 TF Machine parameters: Max. wire tensile strength: up to 600 N/mm² or 85 Ksi Wire diameter: From 2.5 to 14 mm These machines enable us to create complex and precise shapes according to specifications, ensuring high quality and customer satisfaction.

Request for a quote

ORGECO SPOL. S R.O.

Slovakia

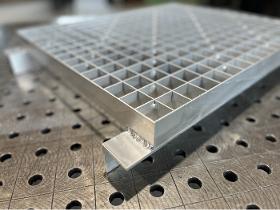

Our company specializes in manufacturing aluminum sheet metal grids, a crucial element in various applications. We offer a diverse range of sizes and styles tailored to individual customer needs.. Leveraging cutting-edge technologies such as laser welding, CNC sheet metal bending, robotic welding, and robotic grinding, we achieve unparalleled precision and efficiency in production. Committed to upholding the highest quality standards, we ensure each product meets all customer specifications. Our experienced and skilled team is dedicated to providing satisfaction and fostering long-term partnerships with our clients

Request for a quote

ORGECO SPOL. S R.O.

Slovakia

We specialize in the production of metal welded brackets according to the individual drawings and requirements of our customers. We are able to provide high-quality products that precisely meet the needs of our clients. Our production is based on the latest technologies in the industry. We utilize laser cutting and CNC bending of sheet metal, which allows us to achieve high precision and repeatability in our products. Thanks to robotic grinding, we are able to achieve optimal surface quality, ensuring consistent and aesthetically appealing surface finishing. One of the key aspects of our production is ensuring a high standard of corrosion resistance and safety for our customers. For this purpose, we use top-of-the-line COSTA machinery, which allows us to round the edges of components with precision and efficiency. This process not only enhances the aesthetics of our products but also increases their durability and resistance to external influences.

Request for a quote

ORGECO SPOL. S R.O.

Slovakia

We specialize in the custom fabrication of sheet metal components to the exact specifications specified in our customers' drawings. Our advanced technologies, including laser cutting and precision CNC bending, ensure accurate production to customer specifications. In addition, our robotic welding and grinding stations ensure high-quality surface finishes and consistency of production. Thanks to our dedicated CNC surface finishing centre, we can achieve the required material readiness for surface finishing. Our commitment is to deliver products that not only meet, but exceed the expectations set out in the customer's drawings, ensuring the satisfaction and reliability of every part produced.

Request for a quote

ORGECO SPOL. S R.O.

Slovakia

Our company specializes in the production of welded metal constructions tailored to customer requirements. The materials we use include steel, aluminum, and stainless steel. Our processes incorporate cutting-edge technologies such as laser cutting, CNC sheet metal bending, robotic welding, and robotic grinding. In collaboration with our partners, we also address surface finishing solutions, including powder coating, hot-dip galvanizing, electroplating, pickling, and passivation. We take pride in the quality and precision of our products, ensured by these technological innovations. With our focus on technological advancement, we are capable of meeting even the most demanding requirements of our customers.

Request for a quote

ORGECO SPOL. S R.O.

Slovakia

Our company specializes in manufacturing fan housings - fan house, which constitute a key part of cooling units. We offer a wide range of types and sizes according to individual customer requirements, manufacturing these components from steel, stainless steel, and aluminum. We utilize the latest technologies including laser welding, CNC sheet metal bending, robotic welding, and robotic grinding, enabling us to achieve high precision and efficiency in production. We are committed to adhering to the highest quality standards, ensuring that each product meets all customer requirements. Our experienced and skilled team is dedicated to providing satisfaction and long-term partnerships with our clients.

Request for a quote

ORGECO SPOL. S R.O.

Slovakia

Our company specializes in manufacturing protective covers for fans - fan guards, using materials such as wires, their combination with sheet metal, and even stainless steel. We are committed to providing safe options for fan protection and ensuring smooth operation. Our products are meticulously designed with a focus on quality and longevity, guaranteeing reliable protection for your equipment. Proudly, we employ innovative approaches that allow us to continuously enhance our products and adapt to the evolving needs of our customers. With a diverse range of over 200 different types of covers available, we tailor our production to meet specific customer requirements and specifications. Contact us today, and let us assist you in enhancing the safety of your equipment.

Request for a quote

DERYA M.D.M SAN. VE TIC. A.S / GLASSYMOULD®

Turkey

Block Press Mould with Copper cooling studs

Request for a quote

GLOBAL METAL COMPANY

United States

If you are a hardware store owner, retailer, online seller, architectural firm, restoration consultant or a B2B company, you can order free samples for review. Step 1: Decide the category / material / finish / design of the product you wish to order. Step 2: Tell us as much details about the desired products as you can. It will help us in identifying the exact product or the closest match. Step 3: Share your complete mailing address and the account number of any of the international courier companies such as FedEx/UPS/DHL, etc. Step 4: If you do not have an account with any international courier companies, don't worry. There are two options - first option is to open a new account with a courier company of your choice or the second option is to pay us the shipping charges and we will take care of the rest. Email us for more details: contact@globalmetal.company

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

AKTAPROM

Ukraine

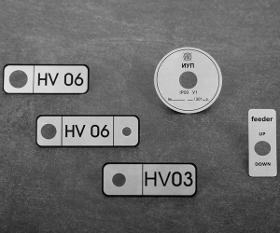

These labels are the last line of defense before someone, gets hurt. The labels are fixed to the items or located on stands in special areas, they warn persons about possible risks, which are associated with usage of different equipment, dangerous areas which are under reconstruction, forces of nature etc. They are necessary for keeping people aware of any danger that may happen. It is a big advantage when labels are fixed in places, without such effects on them as: UV sunrays, acids, abrasives, cleaning liquids etc. In case, when the tags are under influence of negative environment, we provide our clients with anodized aluminum labels, which can resist any severe environment, due to hard aluminium layer, which covered printing, our labels remain anew with the same brightness without any changes. We would like to offer different types of such labels as: electrical warning labels, electrical shock notice, electrostatic warning labels, lockout labels, safety lockout labels.

Request for a quote

AKTAPROM

Ukraine

Push buttons are widely used in different spheres, especially in industrial sphere. This is electrical component, that can make or break electrical circuit. Thus it controls different electrical processes, starting from the simplest lamp and proceeding with complex machine lines. Generally, push buttons are made in a round shape to fit the human finger. We would like to offer different overlays for push buttons, which are considered to be indispensable part for control/facial panels. These overlays are stuck on the button surface and indicate distinctly their application. It helps the operator to anderstand all commands visually. Our company has its own production of marking items based upon own anodized aluminum method named Alumaproof.

Request for a quote

METALUX

North Macedonia

Equipped with plaster protection on the back and lower front. Enclosure, and door in galvanized steel. The telescopic door frame and the door are painted with powder coating. Adjustable depth and height. The manifold cabinets can be made to any size and specification. We can work from your drawings or samples.

Request for a quote

BILSA SAVUNMA TEKNOLOJILERI A.S.

Turkey

Metal Injection Molding can produce complicated and challenging parts in high quantities concerning their precision and fineness, and it offers several advantages over other manufacturing methods. -High surface quality -Reduced production time -Mechanical properties superior to castings -Ability to meet narrow dimension tolerances -High density -Mass production -Net-shape manufacturing with minimal material waste MIM eliminates the limitations and long efforts in standard production methods. It is a superior production method with other advanced applications, and also an advantageous option at a low cost.

Request for a quote

BILSA SAVUNMA TEKNOLOJILERI A.S.

Turkey

Bilsa works with many companies around the globe - in the industries of defence, automotive, medical, electric, hand tools, and textile. Our customers are well aware that they choose us not only for production but the service we provide them. Our experts will lead you to receive the best manufacturing quality. No matter what the volume is, we make sure to meet the desired quality and the performance. We manufacture to create the excellence that our customers deserve.

Request for a quote

BILSA SAVUNMA TEKNOLOJILERI A.S.

Turkey

Metal Injection Molding can produce complicated and challenging parts in high quantities concerning their precision and fineness, and it offers several advantages over other manufacturing methods. -High surface quality -Reduced production time -Mechanical properties superior to castings -Ability to meet narrow dimension tolerances -High density -Mass production -Net-shape manufacturing with minimal material waste MIM eliminates the limitations and long efforts in standard production methods. It is a superior production method with other advanced applications, and also an advantageous option at a low cost.

Request for a quote

BILSA SAVUNMA TEKNOLOJILERI A.S.

Turkey

Bilsa works with many companies around the globe - in the industries of defence, automotive, medical, electric, hand tools, and textile. Our customers are well aware that they choose us not only for production but the service we provide them. Our experts will lead you to receive the best manufacturing quality. No matter what the volume is, we make sure to meet the desired quality and the performance. We manufacture to create the excellence that our customers deserve.

Request for a quote

BILSA SAVUNMA TEKNOLOJILERI A.S.

Turkey

Metal Injection Molding can produce complicated and challenging parts in high quantities concerning their precision and fineness, and it offers several advantages over other manufacturing methods. -High surface quality -Reduced production time -Mechanical properties superior to castings -Ability to meet narrow dimension tolerances -High density -Mass production -Net-shape manufacturing with minimal material waste MIM eliminates the limitations and long efforts in standard production methods. It is a superior production method with other advanced applications, and also an advantageous option at a low cost.

Request for a quote

PULVER.PRO

Ukraine

Mass production of metal bodies, finished steel frames, home appliances and many other products from metal.

HIPRUN POMPA VE CNC EKIPMANLARI

Turkey

Double filtration system is used in our high pressure coolant sytems. They are easily removable and cleanable. On the other hand, especially the main feature of this system is not to be obligated to stop machine during cleaning and changing filter. One filter can be operated with machine while another is been cleaning. This will provide you the time saving during filter change Multiple Manifold Block with 4 outlets is provided as standart in this model. However, it can be manufactured over 4 outlets depending on your requirements at your machining process. HP2 High Pressure Coolant Units are used as mobile station. They have wheels under units and you may easily move it where you prefer them to be placed at your workshop.

Request for a quoteResults for

Finished metal products - Import exportNumber of results

28 ProductsCountries

Company type

Category