- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- industrial robots

Results for

Industrial robots - Import export

SAMSYS GMBH

Germany

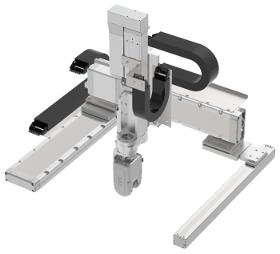

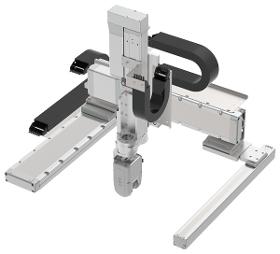

Smart cable routing Compact and flexible installation Easy programming Multipurpose usage Software Built-In PLC

Request for a quote

SAMSYS GMBH

Germany

Smart cable routing Compact and flexible installation Easy programming Multipurpose usage Software Built-In PLC

Request for a quote

SAMSYS GMBH

Germany

Smart cable routing Compact and flexible installation Easy programming Multipurpose usage Software Built-In PLC

Request for a quote

BVS ELECTRONICS GMBH

Germany

CNC systems, industrial robots and accessories for every requirement Products manufactured by Fanuc stand for the highest quality and meet the user's specific requirements. We have particularly specialised in CNC systems, industrial robot components, drives and motors for the globally leading company that specialises in the factory automation sector. With our extensive portfolio consisting of repair, sale and service we will be happy to help you at any time – regardless of whether you have got a faulty FANUC module or quickly require a replacement or new part. With over 40,000 FANUC assemblies, we have a suitable solution for every requirement.

Request for a quote

SAMSYS GMBH

Germany

Smart cable routing Compact and flexible installation Easy programming Multipurpose usage Software Built-In PLC

Request for a quote

SAMSYS GMBH

Germany

Smart cable routing Compact and flexible installation Easy programming Multipurpose usage Software Built-In PLC

Request for a quote

ARTHUR WEISSBACH GMBH MASCHINENFABRIK

Germany

We also create the programs ourselves to “breathe life” into machines and robots. After commissioning, we can run extensive performance tests. Industrial robots are the optimal solution for complex movements or systems with highest flexibility. We integrate and program the appropriate robot such as the Kuka robot and other brands.

Request for a quote

IAI INDUSTRIEROBOTER GMBH

Germany

With the robot wrist unit cartesian systems for the first time have the same flexibility and degrees of freedom as articulated arm robots. Only much cheaper and with much less space requirement. Moreover, IAI's unique design makes the components light and compact. Can also be used for an orthogonal axis system with interpolation function. The innovative wrist unit has two joints: The tilting joint for swivelling has a working circle of ±100⁰ while the rotary joint can be rotated around ±360⁰. The two pulse motors accelerate these cylinders at speeds of between 750 ⁰/s and 1,200 ⁰/s.

Request for a quote

IAI INDUSTRIEROBOTER GMBH

Germany

SCARA robots are often used for the fast removal and movement of workpieces, smaller assembly applications such as screwing in screws, and for the precise dosing of liquids, adhesives and sealants. IAI offers a wide range of models, from the low-cost entry model IXP to the latest IXA high-performance SCARA robot.

Request for a quote

IAI INDUSTRIEROBOTER GMBH

Germany

Water and dust protected SCARA robots SCARA robots are also a popular option for small robotic assembly applications in harsh environments with suspended dust, moisture or water spray. IAI offers water and dust protected SCARA robots with 24 V stepper motor or 230 V servo motor. They can be used without further construction measures. The danger of leakage is not given here. One reason for the uncomplicated installation without the need for additional aggregates are their flexibility and the small footprint, which reduces the cost and time required for commissioning.

Request for a quote

IAI INDUSTRIEROBOTER GMBH

Germany

Suitable robots for almost every requirement What started with the first "intelligent" actuators at IAI today includes a wide range of industrial robots for all automation technology. The range includes cartesian robot systems, tabletop robots and SCARA robots. Matching controller with all common fieldbus connections complete the offer.

Request for a quote

IAI INDUSTRIEROBOTER GMBH

Germany

IAI Industrial Robots is one of the leading manufacturers of electric actuators and industrial robots. In addition to catalogue products, we also offer customised products and special developments. Actuators from IAI can be easily connected to automation applications and integrated into production lines in all industries. The controllers can be connected to the higher-level controller via digital I/Os or via fieldbus systems such as Profinet, Profibus, CC-Link, DeviceNet, EtherCat, EtherNet, Modbus and many more.

Request for a quote

IAI INDUSTRIEROBOTER GMBH

Germany

Cartesian robots can be adapted very well to the respective application conditions due to their modularity. They also take up less space than 6 axis robots, for example, because they only have the functionalities that are actually needed. IAI offers rectangular robot as 2-6 axis combinations with 230 V servo motor in hundreds of configurations as standard or precision types. An equally comprehensive portfolio of cost-effective Cartesian RoboCylinders is available. There are 396 possible combinations for them, including cable chain selection even 7056.

Request for a quote

OTC DAIHEN EUROPE GMBH

Germany

With repetition accuracy of up to ± 0.07 mm, the new high accuracy robot can succeed in even the most demanding of tasks. The deviation from circular diameters of ≤ 10 mm is max. 0.09 mm - half as much as with commercial robots. • Position Accuracy: Highest precision regardless of robot position. • Precision machining: The best choice for laser welding and cutting, TIG, and other tasks requiring high accuracy. The best choice for laser welding and cutting, TIG, and other tasks requiring high accuracy. The main technical specifications at a glance: Number of axes: 6 Working Range (P-Point): R 1664 mm Max. payload capacity: 20 kg Positional repeatability: +/- 0,08mm Drive System: AC Servo Motor Drive Power: 7900 W Weight: 355 kg

Request for a quote

OTC DAIHEN EUROPE GMBH

Germany

The FD-H5 (H) is a compact, high-speed handling robot for small loads. A larger free space in the area of the joint creates a large arm space. Like all robots in the FD series, the H5 model also has collision protection through improved fault detection / elimination. In addition, the integrated hose package guarantees optimal protection against getting caught during the robot operation. The most important technical data: Number of axes: 6 Working range (P-Point): R 866 mm Max. payload capacity: 5 kg Positional repeatability: +/- 0.05 mm Drive System: AC Servo Motor Drive Power: 1440 W

Request for a quote

OTC DAIHEN EUROPE GMBH

Germany

Metalworking companies are increasingly looking for practical solutions on how to quickly and easily carry out welding tasks. For small quantities, however, automation systems for welding have so far been difficult to implement, from an economical point of view. At the same time, it is becoming increasingly difficult to find qualified welders for manual processing. OTC DAIHEN EUROPE has developed EASY ARC, a new mobile welding robot system for workshop operation, which meets the economic and pragmatic requirements. EASY ARC includes a compact welding robot with intuitive OTC Easy-Teach control, which offers the operator with the perfect weld seam, thanks to the integrated expert system and manufacturer’s own 400A MIG / MAG power source inverter. The robot is mounted on a welding table that is prepared for holding standard clamping elements and equipped with rollers. The simple conversion of the system thus ensures appropriate flexibility in production.

Request for a quote

KAWASAKI ROBOTICS GMBH

Germany

The B Series line of body shop robots were developed using Kawasaki's proven advanced technology and extensive automotive experience to take performance to the next level. The robust, yet lightweight slim design achieves the sought after optimization of functionality, flexibility and investment efficiency for maximum spot welding effectiveness and multi-purpose use.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

KAWASAKI ROBOTICS GMBH

Germany

Using Kawasaki's extensive experience in automation and advanced technology, the Z-Series heavy-duty robots were developed. The designs are robust and low-maintenance, being directly responsible for optimizing the efficiency of the production lines in general industry and automotive applications. They have a payload of 165 kg, a repeatability of ±0.3mm and a maximum linear speed of 2,500 mm/s. The horizontal reach is 2.651mm and the vertical reach is 3,415mm. They can be used for a variety of applications including assembly, dispensing, machine tending, material handling, material removal and spot welding.

Request for a quote

KAWASAKI ROBOTICS GMBH

Germany

Designed specifically for palletizing applications, the palletizer series includes five unique robots with payloads from 80 to 700 kg to meet most requirements. Kawasaki's high-speed palletizing robots, industry-leading in work spectrum and reliability, help companies improve the efficiency of their production line.

Request for a quote

KAWASAKI ROBOTICS GMBH

Germany

The new CX series all-purpose large robots are equipped with a light and large arm with a hollow structure and a new universal control unit. They are large all purpose robots for a variety of applications for assembly, spot friction welding, machine loading, material handling, material removal, sealing/metering, spot welding, material handling, etc.

Request for a quote

KAWASAKI ROBOTICS GMBH

Germany

The B Series line of body shop robots were developed using Kawasaki's proven advanced technology and extensive automotive experience to take performance to the next level. The robust, yet lightweight slim design achieves the sought after optimization of functionality, flexibility and investment efficiency for maximum spot welding effectiveness and multi-purpose use.

Request for a quote

KAWASAKI ROBOTICS GMBH

Germany

The B Series line of body shop robots were developed using Kawasaki's proven advanced technology and extensive automotive experience to take performance to the next level. The robust, yet lightweight slim design achieves the sought after optimization of functionality, flexibility and investment efficiency for maximum spot welding effectiveness and multi-purpose use.

Request for a quote

KAWASAKI ROBOTICS GMBH

Germany

Kawasaki's BA Series and RA Series arc welding robots use the latest arc welding technology to compete with the quality of a trained human welder. The robots are equipped as standard with special arc welding software that allows quick and easy programming of the process path. An adaptive welding function is available to change the position of the robot, the shape of the weld seam and the speed during welding in the case of variable weld connections. Their built-in intelligence, flexibility and high accuracy make Kawasaki's arc welding robots ideal for a wide range of arc welding applications.

Request for a quote

KAWASAKI ROBOTICS GMBH

Germany

The M Series Kawasaki Robots are noted for their tremendous power with a torque that makes its extremely powerful. These robots handle a payload of 350 to 700kg and arm length of 2540 to about 3018mm. These machines are cost effective, easy to maintain and repair because they are built with interchangeable modular components. They offer a higher degree of reliability too with their many potential upgrades, greater stability and robustness of machines ensured even in maximum loads. There is no need to do extra wiring to connect the grippers. There are fastening points through which the user can connect lines or hoses. The robot arm in M-Series robot is integrated with signal lines and air hoses. The robots embrace space saving design.

Request for a quote

KAWASAKI ROBOTICS GMBH

Germany

The RS006L is an industrial robot manufactured by Kawasaki. It has a payload of 6kg, a horizontal reach of 1,650mm, a vertical reach of 2,982mm, a weight of 150kg, a maximum speed of 13,700mm/sand, and an integrated E71 controller. Additionally, it uses a brushless AC servomotor, a full digital servo system, and an external motor power. The industrial robot can be used in a wide variety of applications including assembly, dispensing, inspection, machine tending, material handling, material removal, and welding.

Request for a quote

KAWASAKI ROBOTICS GMBH

Germany

HIGH-SPEED, HIGH-PERFORMANCE ROBOT The R series robots are setting the benchmark for all small to medium duty industrial robots. The compact design, along with industry leading speed, reach and work range make the R series robots ideal for a wide range of applications throughout a multitude of diverse industries.

Request for a quote

KAWASAKI ROBOTICS GMBH

Germany

The Z Series heavy-duty robots have been developed using Kawasaki's advanced technology and extensive experience in automation. The rugged and low-maintenance designs are directly critical to the improved efficiency of manufacturing equipment in automotive and general industrial applications as handling robots.

Request for a quote

KAWASAKI ROBOTICS GMBH

Germany

Kawasaki Robotics, one of the industry leaders when it comes to robotics, has managed to come up with this new product as an extension to the previous robot series. The Palletizer series is composed of products that can be used for palletizing applications, delivering superior performance. In addition, the design is a really flexible one and delivers a payload and cycle time that make it easy to adapt to various projects and applications. The 2,800 cycles per hour should be enough to cope even with the most demanding application requirements.

Request for a quote

KAWASAKI ROBOTICS GMBH

Germany

The Kawasaki Palletizing Robots are among the fastest and most reliable machines in the industry. With our newest line of high-speed palletizing robots, the CP series, provides industry leading cycle times and offers a wide range of payload options (from 180 kg to 700 kg) with long reach for increased throughput.

Request for a quoteResults for

Industrial robots - Import exportNumber of results

81 ProductsCountries

Category

- Industrial robots (53)

- Painting robots (35)

- Automation - systems and equipment (24)

- Assembly robots (16)

- Robotics (9)

- Welding robots (4)

- Bearings - ball, needle and roller (1)

- Brakes, servo-brakes and accessories (1)

- Electric cables (1)

- Battery chargers (1)

- Broaches - machine tools (1)

- Construction - Machines & Equipment (1)

- Control switches - electric (1)

- Hoses, pipes and tubes - plastic (1)

- Measurement and control instruments (1)

- Metals - Machines & Equipment (1)

- Welding work - steels and metal (1)