- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- machine tools - metal machining

Results for

Machine tools - metal machining - Import export

SFS GROUP GERMANY GMBH - GESIPA

Germany

Working range Blind rivet nuts from M3 up to M10 of all materials and M12 aluminium and steel, blind rivet nut studs M4-M8 Technical data Weight: 1,25 kg Stroke: 6 mm The GBM 40-R is compact, functional and fast. With its compact design the tool sets blind rivet nuts up to M12. Furthermore the GBM 40-R has a great application access and low weight. The ratchet function provides a very good power transmission. The exchange of nosepiece and threaded mandrel is possible without any tool. Nosepiece and threaded mandrel are also compatible with the GBM 50.

Request for a quote

SFS GROUP GERMANY GMBH - GESIPA

Germany

Working range Blind rivet nuts from M3 up to M10 of all materials and M12 aluminium and steel Technical data Weight: 2.4 kg Stroke: 6 mm The GBM 50 stands for proven technology in a new design. With its compact design the tool sets blind rivet nuts up to M12. Furthermore the GBM 50 has a quick-drill establishment for a simple and safe drilling of the blind rivet nuts. The tool provides low effort by high lever. The exchange of nosepiece and threaded mandrel is possible without any tool. Nosepiece and threaded mandrel are also compatible with the GBM 40-R.

Request for a quote

SAMAG MACHINE TOOLS GMBH

Germany

WE WRITE SERVICE IN CAPITAL LETTERS. – Our customer service does not end with the machine handover! ONLY THE BEST FOR OUR CUSTOMERS. - From production start-up support to constant availability and spare parts supply to individual user training. - Machine installation and commissioning with personal and digital support – individually tailored to your requirements! - Condition monitoring, overhaul and retrofit (SFZ; MFZ; TFZ; TBM) - Machine relocations - Short response times for troubleshooting and repairs - Technological conversion to other components - Maintenance contracts and inspections worldwide for all SAMAG series - On the safe side with us! - Spare parts deliveries at short notice - International service partners - Remote diagnostics via Ethernet interface - 24/7 Service desk - Customized service for your machinery pool - Training and education by our specialists – In-house or directly at your location!

Request for a quote

SAMAG MACHINE TOOLS GMBH

Germany

CUSTOMIZED SOLUTIONS READY TO USE! – The MFZ series offers endless solutions! INNOVATION THOUGHT THROUGH TO THE END! - Modularity in components takes you to the finish line. - Universal machine with 2, 3, or 4 spindles WHETHER DEALING WITH COMPLEX WORKPIECE DIMENSIONS OR IN SEARCH OF THE OPTIMAL QUANTITY SOLUTION WITH MINIMAL MACHINE INVESTMENT – We have consistently evolved our proven machine tool technology. - Extreme adaptability in dimension, material, accuracy, and capacity of your machining task DESIGNED IN THE PROVEN SAMAG CONSTRUCTION, BUT PERFECTED IN MANY DETAILS! – The modular design has significantly expanded the range of workpiece dimensions. - Unique modular system with optional width scaling and thereby correction possibilities in X-, Y-, and Z-direction LOWEST COST PER PART. – MFZ machines operate particularly efficiently, quickly, and dynamically. - Energy, lubricant, and compressed air consumption are significantly reduced

Request for a quote

SAMAG MACHINE TOOLS GMBH

Germany

100% MANUFACTURER-TESTED. – Used SAMAG machines with excellent performance! We don't just manufacture new machining centers; we also refurbish used SAMAG machines! In this process, our experts apply their years of excellent experience in exchanging and assembling parts. We can update your machine to the latest technology upon request. However, technical refurbishment is not our only focus! We pay special attention to energy efficiency and the protection of people and machines through "Safety-Integrated" solutions. Additionally, we make the used machines shine again through thorough cleaning. Certified acceptance criteria ensure excellent machine performance before shipment. This not only demonstrates exceptional sustainability but is also cost-saving for our customers.

Request for a quote

RUF MASCHINENBAU GMBH & CO. KG

Germany

The latest addition to the RUF Maschinenbau portfolio, the low-cost RUF Formica, is a new briquetting system designed for the metals industries. Configured for small to mid sized batches in a wide range of applications, it frees a lot of storage space and simplifies logistics, making it in addition an attractive investment for production companies generating only small chip quantities.

Request for a quote

BRINKMANN PUMPS K.H. BRINKMANN GMBH & CO. KG

Germany

Pressure Boosting Pumps series TH and FH use closed impellers in order to minimize power consumption and to optimize hydraulic pump efficiencies. In addition, the TH series offers high pressures at short immersion depths. Inline pumps of the series FH can be used as boosting pumps if provided with positive inlet pressure. This inlet pressure can be provided by the central coolant supply or a feed pump. In such a setup, pumps of the series FH can raise the incoming pressure by up to 26 bar. A frequency converter can be supplied for special applications or for matching the pump characteristic to a specific duty point. See page "Control/Regulation" in the Technical Information Volumetric delivery: up to 640 l/min Delivery head: up to 520 m Horizontal cutter pumps

Request for a quote

OTTO BIHLER MASCHINENFABRIK GMBH & CO. KG

Germany

Specifications: Pulse rate: max. 200 1/min Processing radius: max. 100 mm Vertical stroke: max. 120 mm

Request for a quote

OTTO BIHLER MASCHINENFABRIK GMBH & CO. KG

Germany

Specifications: Forming force NCA 2: max. 1500 N / 5000 N Stroke: max. 60 mm / 120 mm / 240 mm Forming force NCA 3: max. 3500 N / 8900 N Stroke: max. 120 mm / 200 mm Forming force NCA 4: max. 12000 N / 19000 N Stroke: max. 120 mm Forming force NCA 5: max. 31000 N / 47000 N Stroke: max. 100 mm Forming force NCA 7: max. 190000 N / 200000 N Stroke: max. 140 mm

Request for a quote

OTTO BIHLER MASCHINENFABRIK GMBH & CO. KG

Germany

Specifications: Stroke rate: max. 200 1/min Nominal force: 800 kN Stroke range: fixed stroke with 30 mm Stroke position adjustment: - 8 mm from B.D.C. Tool mounting plate (LxW): 1000 mm x 510 mm Opening size in B.D.C.: 324.5 mm Column opening: max. strip width 160 mm

Request for a quote

OTTO BIHLER MASCHINENFABRIK GMBH & CO. KG

Germany

VariControl VC 1 - One control platform for all tasks With the VariControl VC 1 machine and process control system, Bihler emphasizes the keywords „Ease of Use“ and „Process Safety“ at a new, higher level. With state of the art software and hardware features, the intelligent control system guarantees greater efficiency in your production. The highly flexible control platform allows you to easily control even the most complex automation solutions in the field of stamping and forming assembly technology – on all Bihler machine types. The integrated „bASSIST“ diagnostic and online help system assists your machine operator just like a second operator at his or her side. Videos, graphics and individually created data simplify adjustment, setup and maintenance operations significantly. The continuous monitoring of all machine and tool functions guarantees maximum machine availability.

Request for a quote

ALLMATIC-JAKOB SPANNSYSTEME GMBH

Germany

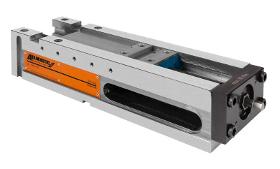

Scope of application: -Horizontal installation – suitable for vertical CNC-controlled milling machines -For automation of machining centres – particularly suitable for batch production Product features: -Extreme accuracy for your machining -The clamping force is generated via the pressure from a hydraulic unit with a hydraulic clamping stroke of up to 4.5 mm -The clamping force is steplessly adjusted by regulating the hydraulic pressure on the hydraulic unit. A hand crank is provided for coarse adjustment of the clamping range -The spindle contains a single-acting hydraulic piston and an additional Belleville spring assembly

Request for a quote

ALLMATIC-JAKOB SPANNSYSTEME GMBH

Germany

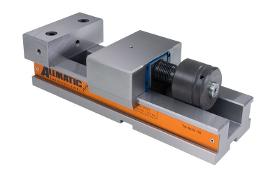

Scope of application: -Can be applied horizontally or vertically – therefore suitable for vertical and horizontal CNC milling machines -Conventional clamping, gripper clamping or pull-down clamping are all possible -Clamping unmachined parts, saw-cut or flame-cut material by penetration of hardened, replaceable gripper elements into the workpiece -With the support jaws, unmachined parts in highly varied materials, or with complex geometries, can be clamped securely and economically. Product features: -High versatility – the modular clamping system combines practically all the possibilities of our tried-and-tested models -The TITAN 2 M is ground an polisched on all sides -High-pressure spindle with power intensification -Enlarged clamping span for secure clamping of unmachined parts -Lost clamping margin 8 mm with pull-down, 3 mm with GRIPPER -Clamping near to neutral axes -Clamping jaws of forerunner are compatible

Request for a quote

ALLMATIC-JAKOB SPANNSYSTEME GMBH

Germany

Scope of application: -Horizontal installation – suitable for vertical CNC-controlled milling machines Product features: -Extreme accuracy for your machining -Clamping force can be preset in 4 to 11 increments. At most, 2 revolutions are required to reach the max. clamping force -Preselectable and reproducible clamping forces enable the workpiece position to be repeated within a tolerance of less than 0.01 mm Important: -LC 200: jaw width 200 mm, width of vice base 164 mm

Request for a quote

ALLMATIC-JAKOB SPANNSYSTEME GMBH

Germany

Scope of application: -Suitable for heavy machining work, single pieces and small batches -Designed particularly for use on conventional milling machines Product features: -Clamping force preselection, 2 to 4 increments, allows accurate repetition (type 100 – 2 increments; types 125, 160 – 4 increments) -Our tried and tested HD vice enables problem-free working with high clamping force and long-term reliability -Particularly suitable for single-piece production if you wish to make your vice rotatable -Can be removed at any time -Swivel base supporting edge larger than the vice‘s maximum clamping range -Swivels 360° without indexing -Alignment on the machine with T-keys in slots in the swivel base -Clamping slots arranged in the form of a ring for machines with different slot spacings

Request for a quote

ALLMATIC-JAKOB SPANNSYSTEME GMBH

Germany

Scope of application: -Horizontal installation – suitable for vertical CNC-controlled milling machines Product features: -Extreme accuracy for your machining -Clamping force can be preset in 4 to 11 increments. At most, 2 revolutions are required to reach the max. clamping force -Preselectable and reproducible clamping forces enable the workpiece position to be repeated within a tolerance of less than 0.01 mm Important: -LC 90: drive head with finer clamping force preselection for sensitive workpieces (11 increments)

Request for a quote

ALLMATIC-JAKOB SPANNSYSTEME GMBH

Germany

Scope of application: -Horizontal and vertical installation – suitable for both vertical and horizontal CNC-controlled milling machines -Lateral installation is also possible Product features: -Extreme accuracy for your machining -The TC vice is ground and polished on all sides -Clamping force can be preset in 11 increments – fine gradations for delicate workpieces. At most, one revolution is required to reach the max. clamping force -Preselectable and reproducible clamping forces enable the workpiece position to be repeated within a tolerance of less than 0.01 mm

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

ALLMATIC-JAKOB SPANNSYSTEME GMBH

Germany

Scope of application: -For horizontal & vertical usage-suitable for CNC controlled milling machines & large machining centres -Clamping unmachined parts, saw-cut or flame-cut material by penetration of hardened, replaceable gripper elements into the workpiece -With the support jaws, unmachined parts in highly varied materials, or with complex geometries, can be clamped securely -Gripper studs suitable for materials with a strength of up toapprox. 1000N/mm² Product features: -High versatility – the modular clamping system combines practically all the possibilities of our tried-and-tested models -Fully compatible with the accessories of the LC/TC 160 series, for example gripper studs, universal gripper set & pull down sets -Grounded sides so that all sides can be used High-pressure spindle with mech. force amplifier for the safe clamping of raw parts in combination with gripping & pull down spring function -Lost clamping margin 8 mm with pull-down, 3 mm with GRIPPER

Request for a quote

ALLMATIC-JAKOB SPANNSYSTEME GMBH

Germany

Scope of application: -The classical, universal clamp, for vertical 3 axis machining centres -Conventional clamping and gripp clamping possible -Clamping of raw parts, burn and saw cuts by penetrating hardened and interchangeable gripp elements into the workpiece Customer advantages: -Free of charge introduction to gripp technology in comparison to conventional clamping (LC) -First and second clamping stations without retrofitting the step jaws Clamping of raw parts such as burn & saw cuts (materials up to approx. 1000N/mm2) through screwable clamping applications (first clamping station) -Parallel clamping to machined workpieces with the step jaws (2. clamping station) Product features: -The high-pressure spindle allows you to, with a mechanical force amplifier (using the torque wrench), to work and clamp to a table -Stable GGG60 body, grounded top and bottom -Precise tracks in the grounded surface of the soles for optimum alignment on the machining table

Request for a quote

ALLMATIC-JAKOB SPANNSYSTEME GMBH

Germany

Scope of application: -Horizontal installation -Suitable for conventional clamping and for gripper clamping or a combination of both -The support jaws enable a wide range of unmachined parts from flame-cut and sawn materials through to complex castings to be clamped securely and economically. Suitable for materials Product features: -Clamping range adjustment for clamping two workpieces of different sizes -Reproducible clamping forces enable excellent repeating accuracy of the workpiece position -Mechanical power-transfer device -Fully enclosed and maintenance-free high-pressure spindle – high chip protection, minimum cleaning requirements, constant clamping forces up to 40 kN -Use with a torque wrench – max. 40 Nm

Request for a quote

ALLMATIC-JAKOB SPANNSYSTEME GMBH

Germany

Scope of application: -Suitable for heavy machining work, single pieces and small batches -Designed particularly for use on conventional milling machines Product features: -Clamping force preselection, 2 to 4 increments, allows accurate repetition (type 100 – 2 increments; types 125, 160 – 4 increments) -Our tried and tested HD vice enables problem-free working with high clamping force and long-term reliability

Request for a quote

ALLMATIC-JAKOB SPANNSYSTEME GMBH

Germany

Scope of application: -Horizontal installation – suitable for vertical CNC-controlled milling machines Product features: -Extreme accuracy for your machining -Clamping force can be preset in 4 to 11 increments. At most, 2 revolutions are required to reach the max. clamping force - Preselectable and reproducible clamping forces enable the workpiece position to be repeated within a tolerance of less than 0.01 mm

Request for a quote

ALLMATIC-JAKOB SPANNSYSTEME GMBH

Germany

Scope of application: -Conventional and CNC-controlled milling machines – for efficient precision machining -Horizontal installation – great variability and flexibility Product features : -Excellent ease of operation guarantees optimal handling in every situation -Fast adjustment for clamping range preselection -The clamping force is generated and preset via the hydraulic pressure of a hydraulic unit -Integrated scrapers ensure functional reliability and minimise cleaning -Fixing on the machine table by means of mounting holes in the vice base. Additional holes can be made in the soft middle section of the vice base -Optional centre jaw allows two or more workpieces to be clamped -Coarse adjustment is performed by turning the spindle. The residual stroke of up to 4.5 mm is performed via a hydraulic unit with spring reset by means of a single-acting cylinder

Request for a quote

ALLMATIC-JAKOB SPANNSYSTEME GMBH

Germany

Scope of application: -Conventional and CNC-controlled milling machines – for efficient precision machining -Horizontal installation – great variability and flexibility Product features : -Excellent ease of operation guarantees optimal handling in every situation -Fast adjustment for clamping range preselection -The clamping force is generated and preset via the hydraulic pressure of a hydraulic unit -Integrated scrapers ensure functional reliability and minimise cleaning -Fixing on the machine table by means of mounting holes in the vice base. Additional holes can be made in the soft middle section of the vice base -Optional centre jaw allows two or more workpieces to be clamped -Coarse adjustment is performed by turning the spindle. The residual stroke of up to 4.5 mm is performed via a hydraulic unit with spring reset by means of a single-acting cylinder

Request for a quote

ALLMATIC-JAKOB SPANNSYSTEME GMBH

Germany

Product features: -Excellent ease of operation guarantees optimal handling for every application -Fast adjustment for clamping range presetting -Reproducible clamping forces are achieved using a torque wrench Integrated scrapers ensure functional reliability and minimise cleaning Fixing on the machine table by means of mounting holes in the vice base. Additional holes can be made in the soft middle section of the vice base Optional centre jaw allows two or more workpieces to be clamped Scope of application: -Conventional and CNC-controlled milling machines – for efficient, precision machining -Horizontal installation – great variability and flexibility

Request for a quote

ALLMATIC-JAKOB SPANNSYSTEME GMBH

Germany

Scope of application: -Horizontal installation – suitable for vertical CNC-controlled milling machines Product features: -Extreme accuracy for your machining Clamping force can be preset in 4 to 11 increments. At most, 2 revolutions are required to reach the max. clamping force -Preselectable and reproducible clamping forces enable the workpiece position to be repeated within a tolerance of less than 0.01 mm

Request for a quote

ALLMATIC-JAKOB SPANNSYSTEME GMBH

Germany

Product features: -Excellent ease of operation guarantees optimal handling for every application -Fast adjustment for clamping range presetting -Reproducible clamping forces are achieved using a torque wrench -Integrated scrapers ensure functional reliability and minimise cleaning -Fixing on the machine table by means of mounting holes in the vice base. Additional holes can be made in the soft middle section of the vice base -Optional centre jaw allows two or more workpieces to be clamped Scope of application: -Conventional and CNC-controlled milling machines – for efficient, precision machining -Horizontal installation – great variability and flexibility

Request for a quote

ALLMATIC-JAKOB SPANNSYSTEME GMBH

Germany

Scope of application: -Horizontal and vertical use - therefore suitable for vertical and horizontal CNC milling machines -Conventional clamping, grip clamping and low tension clapping possible -Titanium 2 K - ideal for use on 5-axis machining centers -Clamping of raw, thermal and saw cut parts by penetrating hardened and interchangeable grip elements into the work piece -The support jaws safely and cost effectively allow raw part, different types of materials and complex geometries to be handled Product features: -To monitor and optimize milling processes -Safety for people and machines -High flexibility - the modular clamping system combines almost all possibilities of our tried and tested models -Titanium 2 M - finely polished sides so that all sides can be used -Titanium 2 K and M can be vertically used Force translated high-pressure spindle -Increased power stroke for safe clamping of raw parts -Loss of 8 mm clamping edge in low tension, 3 mm with GRIPP

Request for a quote

ALLMATIC-JAKOB SPANNSYSTEME GMBH

Germany

Scope of application: -Horizontal installation – suitable for vertical CNC-controlled milling machines -For automation of machining centres – particularly suitable for batch production Product features: -Extreme accuracy for your machining -The clamping force is generated via the pressure from a hydraulic unit with a hydraulic clamping stroke of up to 4.5 mm -The clamping force is steplessly adjusted by regulating the hydraulic pressure on the hydraulic unit. A hand crank is provided for coarse adjustment of the clamping range -The spindle contains a single-acting hydraulic piston and an additional Belleville spring assembly

Request for a quoteResults for

Machine tools - metal machining - Import exportNumber of results

322 ProductsCountries

Company type