- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- tools

Results for

Tools - Import export

OTARA GMBH

Germany

Programmers, testers, tweezers, opening tools, ESD mats, screwdrivers, hygiene Mundex, etc.

Request for a quote

LESJÖFORS INDUSTRIAL SPRINGS & PRESSINGS GMBH

Germany

Modern manufacturing faclilities using the latest in design and production technology ensure consistent, high quality, long life products that are competitive priced.

Request for a quote

BVS ELECTRONICS GMBH

Germany

unipo® software The following options are available for our own brand unipo® software Purchase a reconditioned replacement part or new part Replace a reconditioned replacement part or new part Purchase product overhaul repair or cleaning & inspection services We will be happy to supply an onsite service incl. support over the phone, upon request. Our extensive replacement parts warehouse with more than 100,000 instantly accessible modules provides our customers with a fast supply of replacement parts ensuring the costs of machine downtimes are kept to a minimum. All of the repaired modules, exchange services, and new and replacement part deliveries of unipo® software come with a 24month warranty*.

Request for a quote

XIMEA GMBH

Germany

XIMEA supports more than 30 of the most popular machine vision libraries, including Mathworks Matlab, MVTec HALCON, National Instruments LabVIEW, MicroManager, and OpenCV. The XIMEA CamTool is a cross-platform viewer application that is capable of setting most camera parameters, controlling various features, displaying the video stream, and saving snapshots and sequences. The feature set includes a histogram, line profile, LUT, averaging, flip/rotation, loop recording, shading correction, and more. For rapid prototyping, it is extendable with a scripting engine and custom plugins.

Request for a quote

RONIX GMBH

Germany

Air couplers, also known as air fittings, are essential components in pneumatic systems used to connect various air tools to an air compressor or air hose. They work by using a simple push-and-pull mechanism that allows for quick and easy connection and disconnection of air hoses and tools. Those who work in the automotive, construction, and manufacturing industries, as well as DIY enthusiasts and any other individual that uses compressed air to any extent, may find air couplers beneficial. They are useful for powering various pneumatic tools, such as impact wrenches, spray guns, and sanders. Air couplers are also handy for inflating tires, powering pneumatic nailers, and staplers, and cleaning dusty or dirty surfaces. Featuring a chrome coating and a large body, Ronix 20PP is such an air coupler that can be used in any situation that needs the transfer of compressed air.

Request for a quote

SAMAG MACHINE TOOLS GMBH

Germany

Milling and drilling combined in one machine - In tool and mold making, complex cubic workpieces can be machined precisely, powerfully, safely and from all four sides in just one clamping. The machining centers in the TFZ series cover all requirements in small, medium and large mold making. But TFZ machines are also used in mechanical engineering and the hydraulic industry. You can obtain suitable solutions for machining spindle housings, gear housings or hydraulic cylinders from the deep drilling specialist. Position tolerances in the range of +/-1/100 Angle tolerances +/- 0.02° Surface qualities for ELB drilling Rz 1.6 Cutting volume of 1,600 cm³/min Deep drilling using the ELB process also for diameters larger than 60 mm

Request for a quote

GRUBER SYSTEME HORST GRUBER

Germany

Universally applicable in craft, industry, transportation, business, household and leisure time. ■Reliable arrangement and protected storage of sensitive precision tools and measuring instruments ■Fixation of components, devices and other items on conveyor belts, rotary tables and loading equipments ■Safe transportation of valuable goods ■Easy to cut in any size with scissors or a knife ■Tear-resistant and unbreakable, dirt and water-repellent, easy-care, resistant to deformation in hot and cold conditions Anti-slip mats for tools provide a clear view and order in tool boxes, on assembling dollies and deposit stations.

Request for a quote

LUDWIG HUNGER WERKZEUG- UND MASCHINENFABRIK GMBH

Germany

Right hand cutting solid reamers with extra long shanks. The front end of these reamers is ground to act as pilot. The cutting edges are precision ground with a gradually increasing relief angle to eliminate chattering and to permit easy and smooth chip formation. The reamers are provided with a hard chromium coating. The very hard chromium coating reduces friction, giving improved chip flow and reducing the tendency for built-up edges.

Request for a quote

LUDWIG HUNGER WERKZEUG- UND MASCHINENFABRIK GMBH

Germany

Right-hand cutting reamers with adjustable blades and with extra long cylindrical shank with square. Cutting edges with the unique Hunger special grinding (progressively increasing clearance angle) ensure a soft and smooth cut. A guide bush, which can be supplied in addition to each reamer size and which is pressed against the valve seat during reaming, facilitates handling and enables optimum accuracy. (see leaflet) The blades of the reamer are made of special steel, which is characterized by particularly good edge retention. In the "hard chrome" version, the blades are also hard chrome-plated. The hard chrome layer is characterized by high hardness and low coefficient of friction. Reamers of the "hard chrome" version are therefore particularly suitable for reaming materials with a high wear effect and materials that tend to stick and form built-up edges.

Request for a quote

LUDWIG HUNGER WERKZEUG- UND MASCHINENFABRIK GMBH

Germany

Right-hand cutting shell reamer with expanding blades. Due to the unique Hunger relief grinding operation the blades have a progressively increasing clearance angle giving a soft cutting action. The reamer fits on a tool bar and may be positioned along the tool bar at any desired position. The reamer is automatically locked in place on the tool bar by an expanding spring coupling as soon as the reamer blades are brought into engagement with the bore. Expanding tool bar guides and supporting fixtures for the tool bar are available to ensure excact alignment of the tool bar when reaming a series of aligned holes. The adjusting nut is marked with annular scale. One graduation of the scale corresponds to a change of the reamer diameter by 0,02 mm. The reamers are available with standard blades made of high quality special steel to ensure superior cutting performance. The reamers are also available with hard chromium coated blades.

Request for a quote

LUDWIG HUNGER WERKZEUG- UND MASCHINENFABRIK GMBH

Germany

Application The universal reamer for all types of holes, particularly for in-line reaming of two or more holes and for reaming very long holes. Description Right-hand cutting reamer with expanding blades. Interchangeable pilots with guide sleeves at the front as well as at the back of the reamer. The guide sleeves provide for exact alignment between the hole being reamed and the other mating holes. A special bayonet coupling with mating cones between each pilot and the reamer body ensures correct alignment. Due to the unique Hunger relief grinding operation the blades have a progressively increasing clearance angle giving a soft cutting action. The adjusting nut is marked with a annular scale. One graduation of the scale corresponds to a change of the reaming diameter by 0,02 mm. The reamers are available with standard blades made of high quality special steel to ensure superior cutting performance. The reamers are also available with hard chromium coated blades.

Request for a quote

LUDWIG HUNGER WERKZEUG- UND MASCHINENFABRIK GMBH

Germany

Application The versatile reamer for reaming longer holes and adjacent mating holes. Description Right-hand cutting reamer with expanding blades. Integral pilot with guide sleeves at the front end of the reamer. The guide sleeve provide for exact alignment between the hole being reamed and the other mating hole. Due to the unique Hunger relief grinding operation the blades have a progressively increasing clearance angle giving a soft cutting action. The adjusting nut is marked with a annular scale. One graduation of the scale corresponds to a change of the reaming diameter by 0,01 mm. The reamers are available with standard blades made of high quality special steel to ensure superior cutting performance. The reamers are also available with hard chromium coated blades. The hard chromium coating has superior hardness in combination with a low friction coefficient.

Request for a quote

LUDWIG HUNGER WERKZEUG- UND MASCHINENFABRIK GMBH

Germany

Application The reamer for reaming longer holes and adjacent holes to be reamed in line with each other. Description Right-hand cutting reamer with extra-long expanding blades. The blades are approximately 2/3 longer than the blades of reamer type D. Due to the unique Hunger relief grinding operation the blades have a progressively increasing clearance angle giving a soft cutting action. The reamers are available with standard blades made of high quality special steel to ensure superior cutting performance. The reamers are also available with hard chromium coated blades. The hard chromium coating has superior hardness in combination with a low friction coefficient. Thus reamers of the "hard chromium" series are particularly suitable for reaming abrasive materials and materials with a tendency to adhere to and to build-up the cutting edge.

Request for a quote

LUDWIG HUNGER WERKZEUG- UND MASCHINENFABRIK GMBH

Germany

Right-hand cutting reamer with expanding blades. Due to the unique Hunger relief grinding operation the blades have a progressively increasing clearance angle giving a soft cutting action. Starting with size D 12 the adjusting nut is marked with an annular scale. One graduation of the scale corresponds to a change of the reamer diameter by 0,01 mm. The reamers are available with standard blades made of high quality special steel to ensure superior cutting performance. The reamers are also available with hard chromium coated blades. The hard chromium coating has superior hardness in combination with a low friction coefficient. Thus reamers of the "hard chromium" series are particularly suitable for reaming abrasive materials and materials with a tendency to adhere to and to build-up the cutting edge.

Request for a quote

TANOS GMBH

Germany

Also stackable and connectable with the entire systainer® product range (except for MINI-systainer® T-Loc) With removable insert boxes (2 x small, 2 x medium, 1 x large) Flexible, custom placement Clear organisation for small components Our popular space saver - keep everything clearly organised and close at hand Height with handle*: 233 mm systainer® material: ABS Handle material: PA Cover material: PC * The exterior dimensions are measured without the feet: H + 7 mm with detachable insert-boxes (2 x small, 2 x medium, 1 x big) Outside dimensions H* 160 x W 396 x D 296 mm Height with handle*: 233 mm * The outside dimensions are measured without feet: H + 7 mm

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

KRAMSKI GMBH

Germany

The testing of a new design or process with maximized series-ready specifications – that is the job of our prototyping department. In close cooperation with our customers, we create a sample perfectly matched to the given framework. In addition to our own technologies, we can also integrate processes from our partners (e.g. electroplating or laser processing).

Request for a quote

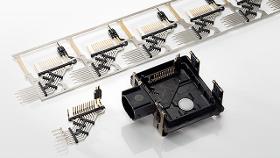

KRAMSKI GMBH

Germany

Compositing of stamped metal insert parts and plastic belongs to our core skills. With our know-how in both technologies, we are able to offer our customers projects and production that push the borders of what is technically possible, when synergistically compositing metal and plastic – and that from us as a single source.

Request for a quote

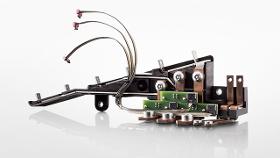

KRAMSKI GMBH

Germany

In stamping technology, many very different technologies can be integrated into the stamping process, such as assembling two or more parts, contact riveting, resistance and laser welding, laser marking of parts, or thread forming. Our high-precision tools, thereby, create a basis for production that is, over its lifetime, very high quality and economical. The stamping process is accompanied by a 100 % quality control of the functional design dimensions.

Request for a quote

KRAMSKI GMBH

Germany

Customized single parts also belong to our services. Based on customer specifications, we manufacture extremely precise and quickly deliverable single parts using various material grades of carbide and steel. This is how we ensure one hundred percent interchangeability following the specifications. We can also contribute to your efficient production run with our high-quality replacement parts.

Request for a quote

KRAMSKI GMBH

Germany

Our core technologies, precision stamping and hybrid technology, are complemented by our special processes (parts cleaning, tumbling, brushing, sand blasting, polishing, laser marking, tape-and-reel, and more). Here, it is all about know-how-intensive processes and work steps, which we specifically use to improve the quality of our products and to hold our promise of KRAMSKI quality in every way.

Request for a quote

SCHOCK GROUP

Germany

Your project is in the best hands at SCHOCK. Our experienced engineers use state-of-the-art methods to plan all resources and guarantee on-time production. In addition, we supervise your tool over its entire life cycle. In mold and tool making, we work with high-quality milling machines, wire and die-sinking EDM machines, and modern CNC-controlled grinding machines.

Request for a quoteResults for

Tools - Import exportNumber of results

823 ProductsCountries

- Germany (823)

- Berlin and region (5)

- Bonn, Düsseldorf and North Rhine and Westphalia (123)

- Frankfurt am Main and Hesse (340)

- Hamburg and region (3)

- Hannover and Lower Saxony (2)

- Kiel and Schleswig-Holstein (20)

- Leipzig and Saxony (2)

- Munich, Nuremberg and Bavaria (92)

- Schwerin and Mecklenburg-Vorpommern (1)

- Stuttgart, Freiburg and Baden-Wurtemberg (209)

- Weimar and Thuringia (26)

Company type

Category

- Tools, pneumatic (217)

- Threading tools (100)

- Tools & Hardware (77)

- Industrial tools (56)

- Cutting - machine tools (50)

- Hydraulic tools (39)

- Laboratory equipment and instruments (31)

- Grinding - machine tools (27)

- Milling - machine tools (19)

- Measurement - Equipment & Instruments (16)

- Drilling - machine tools (13)

- Steels and metals - machining (13)

- Lifting equipment (12)

- Steel, tool (10)

- Stowage - equipment and systems (10)

- Electric tools (8)

- Handling - Machines & Equipment (8)

- Diamond tools (7)

- Foundries - copper, bronze and brass (7)

- Paint mixers and grinding machines (7)