- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- tools

Results for

Tools - Import export

COPIER MACHINERY

Netherlands

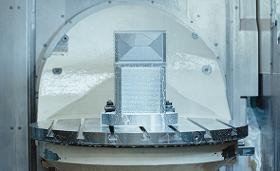

Along with the increasing demand for beveling in several industries, Copier Machinery has been developing the tooling for the best possible result to meet the industry requirements. A limited amount of tooling is used in beveling, which makes the selection of the tooling sets, and cutting bits is essential to get the desired bevel shape. Our R&D team has designed more than 350 sets of machine tooling for simple plain bevel, compound bevel, J-prep bevel, J-prep compound bevel, and internal bevel. They are compatible with Beaver S series. All meeting industry standards and/or customer requirements. If you have a specific production requirement, our team will design a custom tooling set for you.

Request for a quote

INTERLINEX B.V.

Netherlands

Tools reinforces with fiberglass Suitable for the disassembly for door panels, trim, rubber joints, instrument panels, switches and rearview mirror glasses.

Request for a quote

MOH D.O.O

Slovenia

components for making tools for Rubber injection plastic injection high pressure aluminium injection moulding low pressure injection components for making cutting tools components and construction of clamping devices housings holders

Request for a quote

MOH D.O.O

Slovenia

turning inserts for pressure diecasting components for SCR clean diesel technology exhaust components mounting sleeves prototypes sample and ramp up series

Request for a quote

MOH D.O.O

Slovenia

impellers rotors and stators francis impellers pelton impeller impellers castings models

Request for a quote

MOH D.O.O

Slovenia

light housings light rectifiers electronic device housings handles and hooks

Request for a quote

FRIEDRICH AUGUST PICARD GMBH & CO. KG

Germany

The contact wheel FAPI-VUS OPEN is a further development of the dense model. Here the aluminium core is coated alternately with a long and short lamellae of foamed up Vulkollan® . The overall height of the coating must also be adapted to the respective application and is therefore variable (standard: 35 mm). The open model cools better, or respectively it dissipate heat better. The precise adaptation of the soft running cushion to the workpiece makes it possible to achieve high performance results when finishing. Advantages The contact wheels of the FAPI-VUS – series are coated only with lamellae of foamed up Vulkollan® Benefits of contact wheels with lamellae of foamed up Vulkollan® : Highly elastic (adaptable) Wear-resistance Oil-resistance Grease-resistance We will be happy to advise you in order to find a suitable contact wheel for you.

Request for a quote

SCHULZ STANZTECHNIK GMBH

Germany

On request, we can supply ball caster tables / ball transfer units tables adapted to your individual requirements. We usually use sheet metal panels, which are manufactured, edged and welded on all sides, in accordance with your size specifications. The standard table models are galvanised, but can also be supplied with powder-coated surfaces in different RAL colours, in bright steel or stainless steel. Ball caster spacing patterns are manufactured in accordance with your individual requirements. We supply every size of table. In the case of surfaces larger than 2,000×3,000 mm, several table plates are put together to make one table. The ball casters / ball transfer units are mounted by means of press fitting and are easily replaceable. They can be mounted in rows or positioned alternately.

Request for a quote

FRIEDRICH AUGUST PICARD GMBH & CO. KG

Germany

Rollers with a diameter of less than 75 mm are called contact rollers. They are equipped with a metal core flush on both sides and either covered with para rubber or Vulkollan®. The hardness of the coating is usually approx. 60º Shore, but other hardnesses are also possible. The coating of the contact rollers can, for example, be provided with grooves on request. Advantages Advantages of contact rollers FAPI-PA that have these coatings are: Wear resistance Oil resistance Fat resistance Emulsion resistance Ball bearings can also be easily integrated into the metal core from a roll width of 20 mm. Due to these outstanding flexible properties, Picard’s FAPI-PA contact rollers have proven themselves on the market for decades. Vulkollan® = registered trademark of the Covestro Group We will be happy to advise you in order to find a suitable contact role for you.

Request for a quote

FRIEDRICH AUGUST PICARD GMBH & CO. KG

Germany

Uniformly wide polyurethane lamellae are attached in precisely established spacing while plastic foam lamellae are attached in the spaces between them to the aluminium hub of the frequency damped contact wheel FAPI-KS/V FREQUENCY DAMPED. The height of the coating resp. the length of the polyurethane and plastic foam lamellae can be varied depending on the application (standard: 25 mm). The positioning of the lamellae dampens the howling sounds in the upper frequency range in the contact wheel coating during grinding so that they are no longer audible to the human ear. The contact wheel FAPI-PUS/KS frequency damped achieves a significant reduction of the noise level in the workplace and so contributes its share to work safety. Benefits of contact wheels with polyurethane foam lamellae: Highly elastic (adaptable) Wear-resistance Oil-resistance Grease-resistance We will be happy to advise you in order to find a suitable contact wheel for you.

Request for a quote

FRIEDRICH AUGUST PICARD GMBH & CO. KG

Germany

As the name indicates, the aluminium hub of the contact wheel FAPI-VU SMOOTH is coated with a coating of a smooth lamellae of foamed up Vulkollan®. The coating height can be varied depending on the application. Advantages The contact wheels of the FAPI-VU – series are only coated with a lamellae of foamed up Vulkollan®. Lamellae of foamed up Vulkollan® is cellular Vulkollan®, a polyurethane foamed with water which has very high dynamic properties. Lamellae of foamed up Vulkollan® can be identified by its slightly yellowish colour. Benefits of contact wheels coated with lamellae of foamed up Vulkollan® : Highly elastic (adaptable) Wear-resistance Oil-resistance Grease-resistance We will be happy to advise you in order to find a suitable contact wheel for you.

Request for a quote

FRIEDRICH AUGUST PICARD GMBH & CO. KG

Germany

The contact wheel FAPI-VUS/KS is a version coated with lamellae of foamed up Vulkollan® and plastic foam lamellae. The overall height of the coating must also be selected based on the respective application. The alternating lamellae of foamed up Vulkollan® and plastic foam lamellae make the contact wheel especially soft and adaptable. In practice, this contact wheel is used mainly for the finishing of lightly cambered or rounded workpieces. The different material densities result in the heat generated during grinding being drawn off very effectively. Advantages The contact wheels of the FAPI-VUS – series are coated only with lamellae of foamed up Vulkollan® Benefits of contact wheels with lamellae of foamed up Vulkollan® : Highly elastic (adaptable) Wear-resistance Oil-resistance Grease-resistance We will be happy to advise you in order to find a suitable contact wheel for you.

Request for a quote

FRIEDRICH AUGUST PICARD GMBH & CO. KG

Germany

The FAPI–PA MILLED FREQUENCY DAMPED contact disc is the further development of the milled version. Grooves with a groove width-groove depth-web width ratio specially developed by us are milled into the NBR coating of the contact disk. This means that – during the belt grinding process – both the noise level is reduced to a minimum and the material removal rate is increased to a maximum. The total height of the covering can also be selected variably, with the standard height proven in practice being 20 mm. The higher the covering, the more elastic and therefore softer the contact disk surface appears. The contact disks are very aggressive when used due to the grooves they contain. The aggressiveness effect of the contact disk can also be optimized for each application with the milled frequency-damped contact disk by means of an individually optimized groove width-groove depth-web width ratio. We will be happy to advise you in order to find a suitable contact wheel for you.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

FRIEDRICH AUGUST PICARD GMBH & CO. KG

Germany

The expander discs FAPI-PA are an optimal grinding tool for working with all types of sanding sleeves. The expander discs are exclusively provided with a specially slotted NBR coating, which means that the sanding sleeve is tensioned by centrifugal force during the processing process. In practice, the expander discs coated with the material NBR are often simply called “rubber expander discs” or also grinding sleeve carriers.Advantages of expander discs with pararubber coating: - Wear resistance - Oil resistance - Grease resistance - Emulsion resistance We would be pleased to advise you on which expander rolls can be used in your processing, in order to achieve top process results. Please note, other trim types are available upon request!

Request for a quote

FRIEDRICH AUGUST PICARD GMBH & CO. KG

Germany

The FAPI-VU expander discs are an optimal grinding tool for working with all types of sanding sleeves. The expander discs are exclusively provided with a specially slotted coating made of foamed Vulkollan®, which means that the sanding sleeve is tensioned by centrifugal force during the processing process. In practice, the expander discs covered with foamed Vulkollan® (VU) are often simply called “expander discs with foam” or also sanding sleeve carriers.Advantages of expander discs with pararubber coating: - Wear resistance - Oil resistance - Grease resistance - Emulsion resistance We would be pleased to advise you on which expander rolls can be used in your processing, in order to achieve top process results. Please note, other trim types are available upon request!

Request for a quote

ZEMO VERTRIEBS GMBH

Germany

Pneumatic Twin Blade Impulse Wrenches Yokota impulse wrenches are widely used for tightening jobs in the assembly industry, where accurate torque tolerances are necessary. Impulse tools are light, powerful, small and very importantly, have no kick-back, in common with a high repeatability as well as low noise and vibration level. Evaluation of tightening processes in car assembly shows that tightening joints uses 10% of the total assembly time. Working with faster tools therefore can speed up assembly lines substantially. Key Features The patented Twin Blade Impulse Mechanism allows oil-reduced operating. Air treatment unit should be switched-in to decrease wear and maintenance needs. All YX models are equipped with a 2-Step-Trigger. The 3/8” and 1/2” square drive models feature a locking pin enabling fast change of sockets. Models with “A” featuring 1/4” hexagon quick change coupling. Specified technical data are measured on the Yokota testers series YET at a dynamic air...

Request for a quote

ZEMO VERTRIEBS GMBH

Germany

Pneumatic Impulse Wrenches with Double Chamber Air Motor The Yokota Y series impulse wrenches with double chamber air motor achieve the required torque very quickly. The tools have a high number of impulses per second, and therefore very accurate torques can be realised, resulting in increased production speed. Yokota impulse wrenches are widely used for tightening jobs in the assembly industry, where accurate torque tolerances are necessary. Impulse tools are light, powerful, small and very importantly, have no kick-back. Evaluation of tightening processes in car assembly shows that tightening joints uses 10% of the total assembly time. Working with faster tools therefore can speed up assembly lines substantially. Key Features Unique Yokota Twin Blade Impulse Technology reduces noise and vibration level. Generates a high number of impulses per second thus a high accuracy with a shorter production cycle time is achieved. Allowing oil-reduced operating. Air treatment unit should...

Request for a quote

ZEMO VERTRIEBS GMBH

Germany

Pneumatic Impulse Wrenches with Double Chamber Air Motor The lightweight Yokota YLa series impulse wrenches with double chamber air motor achieve the required torque very quickly. The tools have a high number of impulses per second, and therefore very accurate torques can be realised, resulting in increased production speed. Design innovation and the application of new materials significantly reduce the weight and increase the service intervals. Yokota impulse wrenches are widely used for tightening jobs in the assembly industry, where accurate torque tolerances are necessary. Impulse tools are light, powerful, small and very importantly, have no kick-back. Evaluation of tightening processes in car assembly shows that tightening joints uses 10% of the total assembly time. Working with faster tools therefore can speed up assembly lines substantially. Key Features No lube air motor to protect the environment. Extended oil-change intervals. Lightweight. Low air consumption, high...

Request for a quote

FRIEDRICH AUGUST PICARD GMBH & CO. KG

Germany

A wide variety of very individual construction options are made possible with Vulkollan® coated components. Connections between Vulkollan® and metal can be easily created after the metal component has been pretreated. During this pretreatment, the surface of the component is cleaned and degreased using a sandblasting process. An optimal bond is then guaranteed by applying an adhesion promoter. The metal component (e.g. steel, aluminum, cast) takes on the function of the stable supporting body. The Vulkollan® coating meets high-performance requirements in terms of wear protection, damping and noise reduction. We would be pleased to advise you on which metal compounds can be used in your processing, in order to achieve top process results. Please note, other trim types are available upon request!

Request for a quote

FRIEDRICH AUGUST PICARD GMBH & CO. KG

Germany

We manufacture pressure and feed rollers for moulders, feeders and belt sanders according to drawings or samples, completely ready for installation. The choice of roll coating, the design of the roll coating in smooth or grooved form and the most suitable degree of hardness for the roll coating must be determined customer-specifically. Our employees will be happy to advise you by telephone or on site regarding high-quality and cost-effective design of pressure and feed rollers.Harbs rollers consist of a core made of aluminum or gray cast iron. In addition to the polyurethane materials that have long been tried and tested in the wood processing industry, the elastomer Vulkollan® is mainly used for the coating. We would be pleased to advise you on which harbs rolls can be used in your processing, in order to achieve top process results. Please note, other trim types are available upon request!

Request for a quote

FRIEDRICH AUGUST PICARD GMBH & CO. KG

Germany

We manufacture pressure and feed rollers for moulders, feeders and belt sanders according to drawings or samples, completely ready for installation. The choice of roll coating, the design of the roll coating in smooth or grooved form and the most suitable degree of hardness for the roll coating must be determined customer-specifically. Our employees will be happy to advise you by telephone or on site regarding high-quality and cost-effective design of pressure and feed rollers.Gubisch rollers consist of a core made of aluminum or gray cast iron. In addition to the polyurethane materials that have long been tried and tested in the wood processing industry, the elastomer Vulkollan® is mainly used for the coating. The core receiving hole is designed with a feather keyway. We would be pleased to advise you on which gubisch rolls can be used in your processing, in order to achieve top process results. Please note, other trim types are available upon request!

Request for a quote

FRIEDRICH AUGUST PICARD GMBH & CO. KG

Germany

The contact wheel FAPI-VU MILLED is the addition to the smooth model. This is accomplished by milling grooves into the coating of lamellae of foamed up Vulkollan®. The overall height of the coating is also adapted to the respective application and is therefore variable. The grooves can be cut into the coating in various widths, depths and angles. Due to the grooves inserted, contact discs with a milled design are significantly more aggressive than contact discs with a smooth design. The aggressiveness effect of the contact disk can be optimized for each application through an optimal groove width-groove depth-web width ratio so that high-performance processes are possible. With this contact disc, too, no signs of fatigue occur after long, intensive use if used properly.The contact discs of the FAPI-VU series are exclusively provided with a coating made of foamed Vulkollan®. We will be happy to advise you in order to find a suitable contact wheel for you.

Request for a quote

FRIEDRICH AUGUST PICARD GMBH & CO. KG

Germany

The contact wheel FAPI-PUS/KS is an extremely soft version of a contact wheel with a polyurethane foam and plastic foam lamella coating. The overall height of the coating must also be selected based on the respective application. The alternating polyurethane and plastic foam lamellae make the contact wheel extremely soft and particularly adaptable. In practice, this contact wheel is used mainly for the finishing of strongly cambered or rounded workpieces. Because of the different material densities and the spacing between the lamellae heat dissipates very well during the grinding process. Advantages The contact wheels of the FAPI-PUS – series are coated only with polyurethane foam lamellae. Benefits of contact wheels with polyurethane foam lamellae: Highly elastic (adaptable) Wear-resistance Oil-resistance Grease-resistance We will be happy to advise you in order to find a suitable contact wheel for you.

Request for a quote

FRIEDRICH AUGUST PICARD GMBH & CO. KG

Germany

The contact wheel FAPI-PUS OPEN is a further development of the dense design. Here the aluminium core is coated alternately with a long and short polyurethane foam lamella. The overall height of the coating is also adaptable to the respective application and is therefore variable (standard: 35 mm). Because of the variant of the open design, the abrasive belt can better cool because the heat from the belt sanding process is better dissipated. Through the precise adaptation of the extremely soft running cushion to the workpiece that shoud be found it is possible to achieve high-performance results when finish grinding. Advantages The contact wheels of the FAPI-PUS – series are coated only with polyurethane foam lamellae. Benefits of contact wheels with polyurethane foam lamellae: Highly elastic (adaptable) Wear-resistance Oil-resistance Grease-resistance We will be happy to advise you in order to find a suitable contact wheel for you.

Request for a quote

FRIEDRICH AUGUST PICARD GMBH & CO. KG

Germany

With the contact wheel FAPI-PUS DENSE, the aluminium hub is coated with dense adjoining polyurethane foam lamellae. The height of the coating resp. the length of the polyurethane foam lamellae can be varied depending on the application (standard: 20 and 35 mm). The polyurethane foam lamellae provide the contact wheel with a “running cushion” with which a fine finish is possible especially when working on (strongly) cambered and profiled parts. The coating adapts to every workpiece to be found. In addition, the contact wheel FAPI-PUS dense contributes in large measure to abrasive belt cooling because the spaces between the lamellae dissipate the heat generated during belt grinding. Benefits of contact wheels with polyurethane foam lamellae: Highly elastic (adaptable) Wear-resistance Oil-resistance Grease-resistance We will be happy to advise you in order to find a suitable contact wheel for you.

Request for a quoteResults for

Tools - Import exportNumber of results

103 ProductsCountries

Company type

Category