- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- industrial robots

Results for

Industrial robots - Import export

TASK ITALY SRL

Italy

The drying tunnel is used to remove residual water on the external surface of bottles or jars after the filling or pasteurization process. Main construction features include: - Linear stainless steel bottle conveyor belt with adjustable side guides - Structure entirely made of stainless steel, mounted on height-adjustable supports - Upper housing for high-pressure blowing turbines, in stainless steel with sound-absorbing panels - Fully openable plexiglass doors for adjustment of the blowing blades - High-pressure blowing turbines, without the use of electric resistors for low consumption * Specifically designed terminal blades to achieve adequate air force and compression * Adjustable height and inclination of the blowing blades for adaptation to different containers (bottles, jars, cans).

Request for a quote

SAMEC S.R.L.

Italy

The End-of-Arm Tooling system for Sheet Metal handling named Octopus Grip consists in an octogonal-shaped central arm, attached to the wrist of the Robot Grips, specifically studied to be highly resistant to deflections/vibrations, with holes for the internal passage of air, and two or four patented quick ball coupling systems. The quick ball coupling systems allow the reconfiguration of the Robot Grips by simply changing their end effectors, in this case the tentacles of the Octopus Grip, that can be easily unhooked and placed close to the Robot Grips by a single operator on a vertical warehouse, allowing for savings in time required for changing the tools, and in storage space. The Octopus Grip system is highly flexible, from which it derives its name.

Request for a quote

AUTOMAZIONI INDUSTRIALI CAPITANIO SRL

Italy

Automazioni Industriali Capitanio (AIC). AUTOMATIC TAGGING ISLAND is a solution for automatically tagging bundles of profiles, sections and rebars in long product rolling mills. Advantages: - 3D scanning time - 1.2 sec - Full tagging cycle time - 8 sec - Production capacity is up to 180 tph Main Benefits: - Incresed safety and productivity - Efficient and consistent equipment utilization - Cost reduction - Fully finished product tracking system - Tag charger can handle more than 10000 tags Contact us! Tel: +39 0365 826333 Web: http://www.aicnet.it/contacts.html

Request for a quote

SEIT ELETTRONICA SRL

Italy

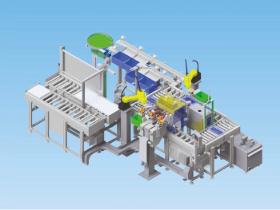

Platinum HUB is a scalable platform you can customize according to your brazing process. You can set up the layout adding multiple stations to: flux, apply brazing paste or pre-formed brazing alloy, wash, dry and cool the parts you are processing, mark with galvo laser technology, and automatic loading and unloading the line using co-bot or industrial robots. This system will for sure adapt to your process and needs and will give you the chance to expand it and add new functions when you really need it. You can use all models of the Platinum series ranging from 2,5KW HF to 25KW MF. The intuitive control system perfectly fits with Seit Elettronica software philosophy: “We provide innovative industrial products with a simple and modern user interface.” These characteristics are pairing and expanding all the new functionalities of “Platinum App” to collect, compare, store and control all the key data from your production as cycle time, temperature and more.

Request for a quote

ARS AUTOMATION

Italy

FlexiBowl® is the flexible parts feeding system for automated production lines using industrial robot or cobots. It is patented and produced by ARS S.r.l. and sold in more than 40 countries worldwide, including through authorized distributors. FlexiBowl® optimizes parts feeding by ensuring more parts are available for pick-up by the gripper in every cycle. The system improves overall feed rates, increases productivity and reduces changeover times.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

Results for

Industrial robots - Import exportNumber of results

5 ProductsCountries

Company type