- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- machine tools - metal machining

Results for

Machine tools - metal machining - Import export

SAMSYS GMBH

Germany

Unloading machine Multi-3000 remove The Multi-3000 remove is an electro-pneumatically controlled automatic unloading machine. It is the ideal complement to the bar feeder Multi 3000 or the Multi 3000SL. With the Multi 3000 remove it is possible to unload finished parts from sub- or main spindle. The bars are unloaded by unloading tube, pneumatic gripper or also by collet chuck. After unloading, the bars are placed on a prism. From the prism the parts are transported to a deposit. A light barrier monitors the unloading process. The coating of the depositing surfaces enables a particularly gentle handling of the finished parts. Even parts such as piston bars can be unloaded without a scratch. The unloading tube is made of POM material. This also ensures gentle handling. Loading can be done via the main spindle and unloading via the sub spindle. It is also possible to load via the sub spindle and unload via the main spindle. Compatible with almost all types of lathes.

Request for a quote

TRANSFLUID® MASCHINENBAU GMBH

Germany

The type UMR tube forming machines use smart operating technology with many predefined settings that can be retrieved automatically to achieve perfect mirror-like surfaces. When producing flares with 20°-90° angles, with a clamping length of 1 x D, the machine achieves perfect sealing surfaces. Flaring up to 90° can be produced in a single cycle. Tools can be changed extremely quickly. With the appropriate tools, the machine can also close tube ends.

Request for a quote

TRANSFLUID® MASCHINENBAU GMBH

Germany

Our rotational technology increases the possibilities of forming on tubes with minimal expenditure on tools. All the drives are servo-electric by design and, if needed, CNC-operated. In our SRM rollforming machines, all the settings are preloaded, so there is no longer any need for costly adjustments. Different tool variants further expand the processing possibilities for chipless cutting or post-bending cutting. The machines can produce internal and external profiles and can also roll in synchronicity thanks to a special tool head (inside/outside).

Request for a quote

TRANSFLUID® MASCHINENBAU GMBH

Germany

Our rotational technology increases the possibilities of forming on tubes with minimal expenditure on tools. All the drives are servo-electric by design and, if needed, CNC-operated. In our SRM rollforming machines, all the settings are preloaded, so there is no longer any need for costly adjustments. Different tool variants further expand the processing possibilities for chipless cutting or post-bending cutting. The machines can produce internal and external profiles and can also roll in synchronicity thanks to a special tool head (inside/outside).

Request for a quote

SFS GROUP GERMANY GMBH - GESIPA

Germany

Contents Blind rivet hand tool NTX and 5 blind rivet sizes, 1 maintenance wrench. Weight: approx. 2.5 kg Dimensions: 275 x 145 x 40 mm Also available as junior riveting kit PolyGrip®

Request for a quote

OTTO BIHLER MASCHINENFABRIK GMBH & CO. KG

Germany

Specifications: Stroke rate: continuously variable up to max. 300 1/min. Press: nominal stamping capacity 200 kN, stroke 12 mm Servo units: max. nominal forming capacity 31 kN, max. stroke 100 mm Feed length: servo feed: any feed pitch Material: max. strip thickness: 4 mm, max. strip width 40 mm, max. wire Ø 4 mm Dimensions: width 2,600 mm x depth 1,900 mm x height 2,650 mm Weight: approx. 4,500 kg (without tooling)

Request for a quote

OTTO BIHLER MASCHINENFABRIK GMBH & CO. KG

Germany

Specifications: Stroke rate: continuously variable up to max. 250 1/min. Press: nominal stamping capacity 300 kN, stroke 60 mm Servo units: max. nominal forming capacity 40 kN, max. stroke 120 mm Feed length: servo feed: any feed pitch Material: max. strip thickness: 4 mm, max. strip width 60 mm, max. wire Ø 4 mm Dimensions: depending on type Weight depending on type

Request for a quote

OTTO BIHLER MASCHINENFABRIK GMBH & CO. KG

Germany

Specifications: Stroke rate: continuously variable from 5 to max. 700 1/min. Press: nominal stamping capacity 300 kN, stroke 10 mm Slide units: max. nominal forming capacity 50 kN, max. stroke 10 mm Feed length: mech. feed: max. 120 mm or 240 mm, with feed cycle reduction, servo feed: any feed pitch Material: max. strip thickness: 4 mm, max. strip width 80 mm, max. wire Ø 4 mm Dimensions: width 2,950 mm x depth 1,400 mm x height 2,190 mm Weight approx. 7,500 kg

Request for a quote

ECKOLD GMBH & CO. KG

Germany

Small and easy to manoeuvre – Mobilformers MZ 30 for vessel flanging These portable forming pliers are the ideal tool for the flanging of cylinders, baffles and cones and can also be used for neck correction and general adjusting tasks. They are available with various quick-exchange tool inserts so that they can be configured to suit any forming task. The pliers are guided by hand along the workpiece. The ECKOLD Mobilformer MZ 30 has been developed for slightly thick sheets of 3.0 – 7.0 mm (steel) and 3.0 – 5.0 mm (stainless steel). Similar to the MZ 20, the MZ 30 is mainly used for the production of vessels and apparatures. This offer includes a hydraulic drive unit HA 510. Tool inserts are not included in the scope of delivery. They must be chosen separately, based on the actual task. Contact us for a customised offer, tool inserts included!

Request for a quote

ECKOLD GMBH & CO. KG

Germany

For high force precision flanging tasks: Portable Kraftformers from ECKOLD This mobile C-frame is generally used for forming and adjusting tasks that require extra force. It is the perfect solution for the flanging of cylinders, baffles and cones as well as for flange repairs. Thanks to the exchangeable tool inserts, the Multiformer is a universal machine that can be configured to handle virtually any forming task. Its roller stops allow for accurate workpiece guidance through the machine. The portable Kraftformer MKF 130/16 is designed for the forming of steel sheets with a thickness from 4.0 to 10.0 mm and for 4.0 to 8.0 mm stainless steel. This offer includes a hydraulic drive unit HA 510. Tool inserts are not included in the scope of delivery. They must be chosen separately, based on the actual task. Contact us for a customised offer, tool inserts included!

Request for a quote

ECKOLD GMBH & CO. KG

Germany

Small and easy to manoeuvre – Mobilformers MZ 20 for vessel flanging These portable forming pliers are the ideal tool for the flanging of cylinders, baffles and cones and can also be used for neck correction and general adjusting tasks. They are available with various quick-exchange tool inserts so that they can be configured to suit any forming task. The pliers are guided by hand along the workpiece. The Mobilformer MZ 20 is the smallest machine of the ECKOLD Mobilformer ranges and therefore very easy to manoeuvre along the workpieces. The pliers are suitable for steel sheets of a thickness from 2 to 4 mm and for stainless steel of a thickness from 2 to 3 mm. The MZ 20 is mainly used for the production of vessels and apparatures. This offer includes a hydraulic drive unit HA 510. Tool inserts are not included in the scope of delivery. They must be chosen separately, based on the actual task. Contact us for a customised offer, tool inserts included!

Request for a quote

BENZ GMBH WERKZEUGSYSTEME

Germany

Angle head 90° Machining: without spatial constraint Optional: with EC

Request for a quote

BENZ GMBH WERKZEUGSYSTEME

Germany

Reducing operating time and downtime Bring together uniform or diverse processing operations to reduce operating times (usually involves multi-spindle heads). The potential applications are virtually limitless: Drilling, threading, counterboring, reaming, milling, etc. The variety of products is equally diverse, from small compact heads with two spindles to multi-spindle XXL units. BENZ offers interchangeable and fixed-flange (stationary) multi-spindle heads in a wide range of configurations. Multi-spindle heads are typically used for mid-size to large-scale series production. We work in close coordination with you, the customer, to find the perfect solution for your application. Using proven standard components as a basis, we create the optimal multi-spindle solution for you. We maintain close contact with leading machine building companies, giving us the necessary expertise to develop the extraordinary. Give us a challenge!

Request for a quote

BENZ GMBH WERKZEUGSYSTEME

Germany

User friendly, stable and very precise. By combining taper concentricity with no backlash with an extremely large planar surface, combined with high torque, BENZ Solidfix® offers a maximum in stability and rigidity, which is even capable of withstanding the demands of milling. The high torque transmission and the highest possible rpms also stress the effectiveness. This is supported by a special clamping mechanism which works centrally, without lateral forces, which in combination with the compact, highly precise components used achieves optimal values for concentricity, rigidity and accuracy in repeatability. Because of its compact design the system is ideal for tools with internal cooling.

Request for a quote

BENZ GMBH WERKZEUGSYSTEME

Germany

Angle head ≠ 90° - with fixed angle Machining: special machining at fixed angle Optional: with IC

Request for a quote

BENZ GMBH WERKZEUGSYSTEME

Germany

Angle head 90° - output spindle on both sides Machining: in opposite direction / with different tools Optional: with EC

Request for a quote

BENZ GMBH WERKZEUGSYSTEME

Germany

Angle head 90° - narrow or extremely narrow design Machining: for extreme spatial constraint / maximum useable tool length Optional: with EC

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

BENZ GMBH WERKZEUGSYSTEME

Germany

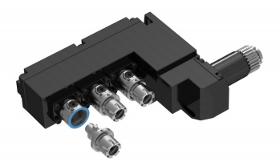

Quick change in confined spaces BENZ Nanofix® is a new quick-change interface that is convincing thanks to its extremely compact design. The outer diameter of 22 mm is designed for minimal spindle distances and is therefore particularly suitable for use in confined spaces.

Request for a quote

BENZ GMBH WERKZEUGSYSTEME

Germany

Angle head 90° - extremely narrow design Machining: for extreme spatial constraint / maximum useable tool length Optional: with EC

Request for a quote

BENZ GMBH WERKZEUGSYSTEME

Germany

Angle head 0-100° - with flexible angle / stepless adjustment Machining: in any variable position Optional: with IC

Request for a quote

BENZ GMBH WERKZEUGSYSTEME

Germany

Increase of efficiency and machining quality The modular quick change system BENZ CAPTO™ guarantees an extremely compact desgin by being integrated into the spindle. Special clamping kinetics for clamping forces are noticeably below the required range of ISO/DIS 26623-2. BENZ CAPTO™ can be used for milling, drilling and turning, with up to 100 bar coolant pressure. The system is especially suited for heavy duty milling and machining.

Request for a quote

GÖCKE GMBH & CO. KOMMANDITGESELLSCHAFT

Germany

Canted profiles in XXL We cant almost every profile with our special tools. Most of the machines used at Göcke are specially constructed; tools for the sheet metal bending presses as well as stencils for sheet metal blanks are self-produced in-house at Göcke. At Göcke Umformtechnik, every desire of the customer and wish for appointments is turned into reality on modern DNC-controlled sheet metal bending presses. For this, we have available an extensive store depot, even special grades. - Cant profiles up to 21 m - Presses up to 3,000 t

Request for a quoteResults for

Machine tools - metal machining - Import exportNumber of results

23 ProductsCountries

Company type

Category