- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- diamond tools

Results for

Diamond tools - Import export

SINAMASTER CUTTING TOOL

Philippines

Tipped PCD insert sizes include: TCGT, CCGT, CCGW, TCGW

Request for a quote

SINAMASTER CUTTING TOOL

Philippines

Tipped PCD insert sizes include: TCGT, CCGT, CCGW, TCGW

Request for a quote

SINAMASTER CUTTING TOOL

Philippines

Brazed CBN insert sizes include: SNGA120408, CNGA120408, TNGA160416, WNGA080408, VNGA160416

Request for a quote

SINAMASTER CUTTING TOOL

Philippines

Dimpled Solid CBN inserts sizes include: SNGX120408, RNGX120400, CNGX120408, TNGX160408, WNGX080408

Request for a quote

SINAMASTER CUTTING TOOL

Philippines

Fulltop CBN insert sizes include: SNGA120408, CNGA120408, TNGA160416, WNGA080408, CCGW09T308, TCGW090204, TCGW110304, SCGW09T304, DCGW11T304

Request for a quote

ÖRNEK ELMAS TESTERE SAN. VE TIC. LTD. ŞTI

Turkey

High quality, extreme longevity. Double row of segments. The holes in the core make the grinding cup suitable for machines with dust extraction. Available in 2 types: concrete and brick. For grinding concrete and hard stone materials.

Request for a quote

ÖRNEK ELMAS TESTERE SAN. VE TIC. LTD. ŞTI

Turkey

Our Core drills are manufactured with optimised diamond secment and welded with the latest Laser welding technology

Request for a quote

HPTEC GMBH

Germany

Allround drill with quiet operation for machining of composite materials such as CFRP and GFRP in the diameter range Ø 0.20 to 6.00 mm. Advantages: Good surface, no delamination and fiber projections, low vibration, ideal for trimming, especially for dry machining suitable (low heat) For advanced materials such as carbon, carbon fiber, glass fiber (fiberglass) with multidirectional and unidirectional fiber orientation Specials: Point angle 90° and extra thick Diamond coating

Request for a quote

PESKA SOLUTIONS

Finland

PESKA’S DIAMOND TOOLS PERFORM BETTER AND LAST LONGER Diamond tools tailored for your production We start from a unique formula for our diamond tools but adjust them for the combination of rock types that you refine. The result is diamond saw blades perfectly tailored for your production, tools that last longer and saw straighter. The Arix Diamond Cutting Blade from Peska Solutions is the ultimate cutting solution for all your stone and masonry needs. With its patented Arix diamond technology, this blade delivers unmatched cutting performance and durability, making it the go-to choice for professionals in the construction and stonework industries. Crafted with precision and designed to cut through even the toughest materials with ease, the Arix Diamond Cutting Blade is engineered for maximum efficiency and safety, reducing cutting time and minimizing operator fatigue.

Request for a quote

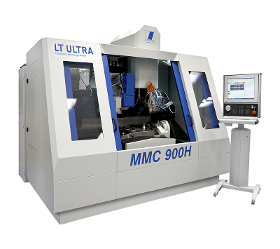

LT ULTRA-PRECISION TECHNOLOGY GMBH

Germany

To create ideal conditions in terms of rigidity and damping for multi-axis machining, the series was equipped with hydrostatic (oil) bearings. By using diamond tools, optical surface quality can be achieved on a wide range of materials like crystals, nonferrous metals and plastics, even with complex geometries. Similar to the MMC 600/900 air bearing machines, the basic setup can be equipped with various accessories. The basic setup consists of 3 linear axes and can be upgraded by additional rotary, tilt or spindle axes to 4, 5 or 6 axes. Accessories, like different spindles, vacuum chucks, palleting systems, 3D touch probes for workpiece measurement, tool changer and automated tool setting, allow an effective use of the machine. Besides further accessories, there is the possibility to develop customized solutions, to adapt the machine to your needs.Please do not hesitate to contact us.

Request for a quote

LT ULTRA-PRECISION TECHNOLOGY GMBH

Germany

To create ideal conditions in terms of rigidity and damping for multi-axis machining, the series was equipped with hydrostatic (oil) bearings. By using diamond tools, optical surface quality can be achieved on a wide range of materials like crystals, nonferrous metals and plastics, even with complex geometries. Similar to the MMC 600/900 air bearing machines, the basic setup can be equipped with various accessories. The basic setup consists of 3 linear axes and can be upgraded by additional rotary, tilt or spindle axes to 4, 5 or 6 axes. Accessories, like different spindles, vacuum chucks, palleting systems, 3D touch probes for workpiece measurement, tool changer and automated tool setting, allow an effective use of the machine. Besides further accessories, there is the possibility to develop customized solutions, to adapt the machine to your needs. Please do not hesitate to contact us.

Request for a quote

SPM - SOCIÉTÉ PYRÉNÉENNE DE MÉTALLURGIE

France

DRILLSTAR fishing magnet is a valuable tool before diamond coring or drilling. Its strong magnetic field will retrieve all types of small steel objects from the bottom of the hole. It is available is a variety of sizes and shapes, to suit the most demanding fishing jobs. Two main designs are available : - Classic design, with a single magnet. - Modular design, using multiple small, high-strength magnets: this design enables a wide range of lifting forces and magnetic surface shapes, using the most powerful magnets available today. Mud ports can be added on the tool bottom or side to clean out the fish. Our magnets are available in two grades, depending on temperature rating : - Normal, up to 300 deg F (150 deg C). - High Temp, up to 570 deg F (300 deg C). Unlike traditional fishing magnets, DRILLSTAR Magnets are permanent and do not require any periodic re-magnetization. High-temp magnets are designed to lose very little force with temperature increase (3% per 100 deg C)

Request for a quote

STARRAG GMBH

Germany

s230 is an automatic solution for faceting and diamond finishing dials index. s230 production center allows the production of a wide variety on index in various metals. Contrasts of different visual effects are performed by the use of diamond tools or solid carbide tools. The complete solution for small and medium series for finishing index combines multiple operations on a single machine. Features Optical recognition and origin definition of blanks Diamond with the revolver toolholder Machining of LuniNova pockets and micromilling Simple programming interface on Windows A variety of automation systems are available to ensure a high level of autonomy in production

Request for a quote

HAN SONG M&T

South Korea

[Product Description] R-PRO series is specialized for cutting super-hardened & heat-treated steel (HRC 52 to HRC 72). It has excellent wear resistance and a shape design for increasing machinability. In addition, we have taper end mills that can be customized to customers. [Product Specification] Flat end mill : D0.1 ~ D12 + Various effective length / total length Ball end mill : D0.1 ~ D12 + Various effective length / total length C/R end mill : D1 ~ D12 + Various effective length / total length Taper end mill : D1 ~ D12 + Various effective length / total length [Product Model] Flat : 2RRE, 4RRE, 4RPE, 4RLE Ball : 2RRB, 2RSB, 2RPB, 3RSB C/R : 4RRR, 4RCR, 6RCR Taper: 2RTB, 3RTB, 2RTR, 4RTR [Product Use] * R pro series is suitable for Super hardened steels (HRC 52~70) and pre-hardened steel * Strong wear-resistance and minimizing chipping by adapting R-pro coating.(Si based PVD coating) * Excellent surface roughness of work pieces due to optimized cutting edge design

Request for a quote

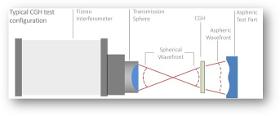

ZYGO CORPORATION

United States

Complex asphere metrology ideally suited for production-level volumes Advances in diamond turning and small-tool deterministic polishing have dramatically increased optical manufacturing capabilities to produce nearly any surface shape. Designers have leveraged these capabilities by increasingly designing aspheric optics into imaging, sensing and laser systems to improve performance and reduce size and weight of optical systems. However, it isn’t just the polishing equipment that is required to produce high quality aspheric optics – metrology is required to guide polishing and material removal from the surface to converge to an ideal surface figure that matches the design closely. A CGH (Computer Generated Hologram) is an optical null element that creates a unique wavefront enabling interferometric testing of complex optical surfaces including freeform, gullwing and off-axis aspheric shapes. Check our products: Zygo’s Verifire VTS and Verifire™ Asphere

Request for a quote

PRECISION SURFACING SOLUTIONS GMBH & CO. KG

Germany

The millGrind series is specially developed for the requirements of machining in the turbine industry as multiple technology solution in one set-up. The modular machine system in travelling table design allows an individual configuration of the machine according to the customers' needs. Automatic tool and diamond roll changing allows the machining to machine with — Al-oxide, CBN and diamond grinding wheels — Drills — Milling cutter — Laser cladding — Measuring of the unfinished workpiece — Measuring of the machine workpiece including rework in one set-up. This guarantees that all machined surfaces run to each other and errors are avoided by repeated re-chucking. In addition to the machining of new blades and vanes for rework a laser cladding device can be added. This allows the measuring, cladding and grinding or milling of the worn areas.

Request for a quote

MICROCERTEC

France

Quartz, or fused silica, can be machined like any other ceramic material thanks to diamond tools. Thus Microcertec can realize customized parts made of quartz with various sizes and shapes, high level of precision but without any optical required performances or surface finish. The most important properties of the quartz is its low coefficient of thermal expansion. From an optical point of view, the quartz is generally transparent to the infra-red wavelenghts. Selection of materials Microcertec uses standard grades of quartz from well-known producers like GE or Heraeus. We machine both quartz standard quality as well as semiconductor and optical grade quartz. Properties From a general point of view, quartz shows : - good electrical insulation - very small coefficient of thermal expansion - good thermal insulation - good thermal resistance - transparence to the infra-reds - vaccum resistance Our typical applications Quartz is mainly used as : - electrical insulators - thermal...

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

KAPP NILES GMBH & CO. KG

Germany

Beside the non-dressable CBN grinding tools, dressable grinding tools of leading manufacturers can be used on our machines, too. Vitrified bond aluminium oxide tools are dominant. Sintered aluminium oxide is preferred as the grinding tool for grinding of steel due to its resilience and grinding capability. Gray cast-iron can also be processed with normal aluminium oxide. The profiling of the grinding tools takes place via a machine-integrated CNC dressing unit. A diamond-plated, rotating dressing tool profiles the wheel in accordance with the respective gear parameters. The grinding tool is conditioned specifically for rough or finish grinding by selecting respective technological dressing parameters. Form consistency and cutting capacity of the grinding wheel is assured by repeated dressings, dependent on pre-defined stock removal rates. The automatic balancing produces smoother turning for larger grinding tools, and consequently, high gear quality. dressable CBN tools Single-layere

Request for a quote

ZINNER GMBH PRÄZISIONSWERKZEUGE

Germany

ZINNER PKD or highly positively polished cutting inserts are used for machining aluminium and copper. Glass-fibre reinforced materials are machined with PKD or coated PKD tools. Diamond tools are ideally suited for the high gloss turning of non-ferrous metals.

Request for a quote

ZINNER GMBH PRÄZISIONSWERKZEUGE

Germany

CBN (cubic boron nitride) is the next hardest material after diamonds. When properly used, tools made from CBN exhibit considerably less wear than other materials. Cutting inserts or even VHM tools can be equipped with CBN. Technical application: Hardened tool steels with hardnesses greater than 55 HRC or high speed steels (HSS) can be machined without problems using CBN. Case hardened steels and chilled cast iron can also be machined with CBN. Non-ferrous metals are totally unsuitable for CBN; diamond tools are needed for these.

Request for a quote

BUFFALO TUNGSTEN INC.

United States

Buffalo Tungsten is been a leading independent manufacturer and supplier of high purity tungsten powders. With over three decades of experience and a sole focus on powdered tungsten materials, our powders meet the highest standards of purity and consistency. Additional processing can be done to meet demanding specifications for both physical and chemical properties. Buffalo Tungsten produces fine tungsten powders from under one micron to coarse tungsten powders in larger mesh sizes. High purity powders with up to 99.999% purity are manufactured as well as high density powders. Various metal additives can produce compositions suited to a wide range of applications. We are a supplier to industries that include additive manufacturing, surface coatings, heavy metal, electrical contacts, diamond tools, radiation shielding, industrial gases, and defense applications. Tungsten carbide powder and tungsten based thermal spray powders are also produced in many standard sizes and specifications

Request for a quote

ASSFALG GMBH

Germany

AF 165 is a tabletop device for the lightning-fast and efficient removal burrs. Faceting and deburring machine with fixed angle of 45° and gradually set chamfer width for all metals. Its special area includes the removal of saw burrs and roughing burrs so that workpieces can be further processed and are safe to use. Fast, cost efficient edge grinding is achieved by durable flap disks, CBN- or diamond grinding wheels. Advantages: Can be used for steels, aluminium, brass, copper, plastics, from soft plastics to acrylic glass, wood and much more. For hardened steels CBN wheels For hard metals Diamond discs Uncomplicated tool change Easy operation

Request for a quoteResults for

Diamond tools - Import exportNumber of results

23 ProductsCountries

Company type

Category

- Diamond tools (6)

- Diamonds, industrial (3)

- Milling - steels and metals (2)

- Adjustment - machine tools (1)

- Cutting - machine tools (1)

- Industrial cutting machine tools (1)

- Industrial tools (1)

- Machine tools, metal machining - parts and accessories (1)

- Metal powders (1)

- Optical measuring equipment (1)

- Tools & Hardware (1)