- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- aluminium alloy die casting

Results for

Aluminium alloy die casting - Import export

FRONTAL ALUMINIUM

Poland

manufactured according to currently applicable standards, such as: PN EN 1676; DIN 1725; PN-76/H-88027;ZN-86/MH-MN-260-14 , as well as according to the chemical composition specified by the customer, Each alloy is filtered and refined and can be modified at the customer's request.

Request for a quote

ZS INDUSTRIES CO., LTD

China

Material: A356, A360, A380, ADC12 Process: Sand casting + machining Gravity casting + machining Die casting + machining Low pressure casting + machining Application: Air compressor Pumps Concrete plant equipment

Request for a quote

MAGMETT METALL INC.

Turkey

ntroducing ALSi, a remarkable aluminum-silicon alloy designed to cater to the needs of the casting industries. Crafted with utmost precision and expertise, ALSi offers unparalleled quality and performance. Our ALSi alloy is meticulously engineered to meet the stringent requirements of casting applications. With its exceptional properties, it ensures superior strength, durability, and impeccable casting results. Not only does ALSi excel in casting industries, but it also finds its utility in powder metallurgy. Its versatile nature allows for seamless integration into various manufacturing processes, expanding its range of applications. Experience the reliability and versatility of ALSi, as it revolutionizes the casting industry with its exceptional performance and unmatched quality. Trust in ALSi to elevate your casting projects to new heights of excellence.

Request for a quote

KIGEMA SP. Z.O.O

Poland

KIGEMA applies centrifugal casting to components using all copper and aluminum alloys covered by international and local casting standards (DIN EN 1982:1998-12, PN-EN 1982, DIN 1705, 1709, 1714, PN 91/H-87026, ASTM B271, BS 1400), as well as using special alloys.

Request for a quote

KIGEMA SP. Z.O.O

Poland

KIGEMA applies centrifugal casting to produce bushes, rings and sleeves using all copper and aluminum alloys covered by international and local casting standards (DIN EN 1982:1998-12, PN-EN 1982, DIN 1705, 1709, 1714, PN 91/H-87026, ASTM B271, BS 1400), as well as using special alloys.

Request for a quote

GLOBAL GASES GROUP THAI CO LTD

Thailand

SIMPLE BUT POWERFUL: XtremepowerUS 1/3 HP 4 CFM 1-Stage Rotary Air Vacuum Pump is designed to have high efficiency and low noise output with internal high volume cooling fan for extended use HEAVY DUTY CASING: Die-cast Aluminum Alloy Casing enables the vacuum pump oe light and durable at the same time. Equipped with brass fitting tethered safety caps to prevent oil leaks during transportation and handling EASY OIL CHANGE: The vacuum pump features a simple Oil Fill Port for a clean pour and Oil Drain Plug positioned beneath the oil reservoir to quickly drain when needed. Checking the spillage meter will help to ensure the proper level of oH PACKAGE INCLUDED: Multicolored set of three 36" hoses, Manifold Gauge, Oil Bottle, Accessories, Leak Detector and Storage Bag to keep equipment clean and dust free and R134a Can Tap

Request for a quote

GLOBAL GASES GROUP THAI CO LTD

Thailand

SIMPLE BUT POWERFUL -XtremepowerUS 1/4 HP 3 CFM 1-Stage Rotary Air Vacuum Pump is designed to have high efficiency and low noise output with internal high volume cooling fan for extended use (Include R-134A automotive air conditioning dispensing valve design with hand operated punch/valve control, connects all R-134a refrigerant cans with 1/4" Male threads)HEAVY DUTY VACUUM PUMP - Die-cast Aluminum Alloy Casing enaDles the vacuum pump oe light and durable at the same time. Equipped with Brass fitting tethered safety caps to prevent oil leaks during transportation and handling.HVAC GAUGE READING - The XtremepowerUS HVAC service gauge set is great for diagnosing and repairing AC systems. Ideal use for R12, R22, R134a and R410aEASY OIL CHANGE - The vacuum pump features a simple Oil Fill Port for a clean pour and Oil Drain Plug positioned Deneath the oil reservoir to quickly drain when reeded. Checking the spillage meter will help to ensure the proper level of oil.

Request for a quote

BACA MAKINE LTD.

Turkey

Steel alloys Stainless steel alloys Aluminum alloys Copper alloys Cobalt alloys Superalloys Cast titanium

Request for a quote

PLANSEE SE

Austria

During the aluminum casting process, the metal melt is either poured or pressed into the mold. This process is used, for example, to manufacture cylinder heads, wheel rims and many other aluminum castings. Here, the mold has to repeatedly withstand the metal melt at a temperature of over 600 °C: for inserts made of our tungsten-heavy metal alloy Densimet® and the molybdenum alloy TZM, that's not a problem. The benefits to you: — Shorter cycle times — Top surface quality for your products — Long mold service life — No cracks in the mold insert Tailor-made mold inserts, sprue bushes, cooling inserts and other individual parts as well as semi-finished products for your mold are available.

Request for a quote

EUROBALT ENGINEERING OÜ

Estonia

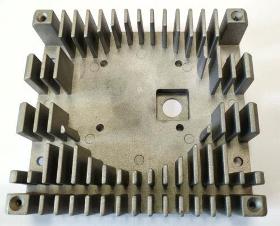

Metal die casting – is a production technology of castings, in which the alloy under pressure up to 700 MPa quickly fills the mold. Products made in this way can be of different sizes and have weigh up to several kilograms. As a basic raw material normally are used following: non-ferrous metals — copper, aluminum, and their alloys. Die casting makes it possible to obtain high-precision products (along with such technology as powder metallurgy, which allows to obtain sintered metal parts that are particularly hard and wear-resistant). Our company offers the manufacture of parts for LED lighting and other high quality castings. One of the main advantages of die casting is the resistance of finished products to corrosion. The fact is that in the process of their manufacture a strong surface crust is formed, which has a high density and low moisture permeability.

Request for a quote

TURKOGLU

Turkey

Overground Fire Hydrant / Body, Lower and Upper Pipe: GG-25 Cast Iron / Coupling: Aluminium Alloy / Handwheel : GG-25 Cast Iron / Disc : GGG-40.3 Ductile Iron / Check Valve: Brass / Upper shaft : Stainless Steel / Shaft motion pipe: Galvanized steel or Stainless Steel ** Application area: Fire installations

Request for a quote

MODULUS METAL

Turkey

Milling Drilling Turning / Boring / Parting Reaming Broaching Planning, Shaping, Slotting

Request for a quote

MODULUS METAL

Turkey

Modulus Metal has ISO / IATF certified die casting supplier base, mainly in aluminum high pressure die casting, and our partner suppliers are experienced in automotive, aerospace, agricultural and industrial machinery manufacturing for many years. Production capabilities: Up to 10 kg /piece Quantity: Mainly high volumes of production due to tooling cost Aluminum,As Cast,Wrought,COPPER,Aluminum Bronze, Brass, Bronze, Coated Copper, Copper-Nickel, Silicon Bronze,ZINC,Aluminum Alloy : Forming Die Alloy, General Casting Alloy, Pressure Die Casting Alloy, Slush Casting Alloy, Wrought,Commercial Purity,Copper Alloy : Pressure Die Casting Alloy , Wrought

Request for a quote

ARNTZ GMBH + CO. KG

Germany

Engineered for : • Aluminium alloys • Aluminium bronzes • Copper alloys • Sand cast aluminium and cast magnesium • Graphite

Request for a quote

VERFAHRENSTECHNIK HÜBERS GMBH

Germany

Impregnation systems to close micropores in metal castings as well as in copper, aluminium or magnesium alloy castings. The parts to be impregnated are fixed in baskets. The latter are transported by a special crane system as well as with reservoir roller conveyors. Excess material is removed by centrifuging of the baskets. The impregnating agent remaining in the pores in fluid form is hardened by heating in a hot water bath. The process sequence runs fully automatically under a microprocessor control.

Request for a quote

CRONOS DIS TICARET LTD.STI

Turkey

– Iron (pig, ductile iron), aluminum, steel and special alloy casting parts – Sand, gravity, centrifugal, continuous, metal injection and precision casting parts – Casting, machining, coating processes – All quality control tests (tensile, rupture, penetrant, tightness, CMM etc.) – Quality control reporting at all levels Our casting suppliers are companies that mostly work with abroad, have the necessary technical infrastructure, and are fast and solution oriented. We work with experienced suppliers who have the necessary laboratory facilities and quality documents.

Request for a quote

WENZHOU DONGYI MACHINERY MANUFACTURING CO,.LTD

China

FOR A WIDE RANGE OF OPERATING CONDITIONS Our factory manufacture to the highest quality standards a full range of pistons and piston rods in stainless or alloy steels, aluminum and cast iron, for a broad range of applications and operating conditions. Experienced technical knowledge of compressor design and operation ensures that the optimum materials, surface treatments and sealing components are selected for each application. FEA analysis is used to ensure the design meets all of the highest engineered standards to guarantee product integrity and quality. Piston and Rod Reconditioning All pistons and rods are inspected to assess how to proceed with reconditioning and to ensure their suitability for re-use. Piston reconditioning may include re-machining of grooves and re-anodizing. Rod reconditioning may include machining, grinding, polishing and the application of specialized spray coatings. Finally, all parts are re-assembled including piston and rider rings.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

EXOTERM-IT D.O.O.

Slovenia

ALUTIL MOP 417 is an non-pigmented dressing of petroleum, based on mineral oils. It is applicable for die-castings zinc and aluminum alloys.

Request for a quote

EXOTERM-IT D.O.O.

Slovenia

EXO – COATING ZG 3V is an alcohol -based dressing. Its characteristic is a high refractoriness and a wide range of applications. Purpose of use: Aluminium and aluminum alloys, Steel castings, Nodular graphite cast irons, grey cast irons, other colored materials

Request for a quote

EXOTERM-IT D.O.O.

Slovenia

POPEX is an adhesive for cold sticking of sand cores and moulds. It is a paste of bright brown color. Used in Aluminium and aluminum alloys, Steel castings, Nodular graphite cast irons, Grey cast irons, Other colored materials,

Request for a quote

EXOTERM-IT D.O.O.

Slovenia

AQUADUR M-15 is a water-based ceramic dressing in pasty form. Its characteristic is a high refractoriness. Approximate composition: about 60 % refractory filling (Al and Mg silicates, Fe oxide) about 6 % organic binder about 34 % water Purpose of use: Aluminium and aluminum alloys, Steel castings ,Nodular graphite cast irons, Grey cast irons, Other colored materials

Request for a quote

BIBIELLE S.P.A.

Italy

These are similar to the Satin Machine wheels but are made laying the non woven in a way that waved edges are obtained. Features and benefits: For applications on wide areas which require a higher uniformity finishing, the RFV allow a higher uniformity among the various steps on the surface. Recommended applications: Satin finishing large surfaces. Work surfaces: Stainless steel, standard or alloyed steel, nonferrous metals and alloys, aluminum, cast iron, titanium, plastic.

Request for a quote

BIBIELLE S.P.A.

Italy

These wheels on 6-mm shaft are made of a combination of cloth flaps and High Performance Nonwoven material. To be used on straight grinders. Main features and benefits: Thanks to the abrasive cloth the scrubbing action of BIBIELLE shaft-mounted nonwoven wheels is more aggresive whilst ensuring high finishing quality, excellent user friendliness combined with highly efficient ventilation and low-noise levels typical of nonwoven products. Recommended applications: Light deburring and cleaning parts of irregular shape, pipes or moulded parts. Removing scale. Removing marks left by previous operations. Work surfaces: Stainless steel, standard or alloyed steel, nonferrous metals and alloys, aluminium, cast iron, titanium.

Request for a quote

BIBIELLE S.P.A.

Italy

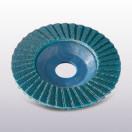

Y-weight polyester backing, Zirconium grain with cooling additive, double resin, closecoat. Main features and benefits: This product is particularly suitable for applications requiring highly efficient removal, extremely quick cutting performance and low operating temperature. This product can be supplied in customised sizes. Recommended applications: Deburring, removing protruding welded surfaces and excess material, removing scale. Work surfaces: Stainless steel, alloyed steel, aluminium, cast iron.

Request for a quote

BIBIELLE S.P.A.

Italy

Aluminium oxide bands to be used (with suitable expanders) on satin finish machines. Main features and benefits: Thanks to their wide abrasive area, they allow operators to rapidly and efficiently work on a wide range of surfaces. Recommended applications: Light deburring, cleaning, finishing small and large surfaces. Removing scale or marks left by previous operations. Work surfaces: Stainless steel, standard or alloyed steel, nonferrous metals and alloys, aluminium, cast iron, titanium, plastic, wood.

Request for a quote

BIBIELLE S.P.A.

Italy

Economic version of the flap discs. Available in back up pad discs and fiberglass version. Features and benefits: These discs offer good cutting and have a good ratio cost/performance. These are particularly suitable for non continuous processing where cutting speed and costs are the main elements. Recommended applications: Deburring, removing welding seams and spots, removing scale, rust and oxidation of any kind, blunting sharp corners and edges. Work surfaces: Stainless steel, alloyed and unalloyed steel, aluminum, nonferrous metals and alloys, structural steel, cast iron, titanium, plastic, pain, varnish, filler.

Request for a quote

BIBIELLE S.P.A.

Italy

Economic version of the flap discs. Available in back up pad discs and fiberglass version. Features and benefits: These discs offer good cutting and have a good ratio cost/performance. These are particularly suitable for non continuous processing where cutting speed and costs are the main elements. Recommended applications: Deburring, removing welding seams and spots, removing scale, rust and oxidation of any kind, blunting sharp corners and edges. Work surfaces: Stainless steel, alloyed and unalloyed steel, aluminum, nonferrous metals and alloys, structural steel, cast iron, titanium, plastic, pain, varnish, filler.

Request for a quote

BIBIELLE S.P.A.

Italy

Overlapped pairs of zirconium flaps and X-weight backing. Only the flat version is available. Main features and benefits: The zirconium abrasive is particularly suitable for applications requiring high operating pressure and even for medium/high-power cornering grinders. The flap paired arrangement provides better ventilation and improves scrap/waste escape. Wide abrasive surface, constant wear, continuous exposure of new grit, high and even cutting performance. Recommended applications: Deburring, removing welding seams, blunting sharp corners and edges. Work surfaces: Stainless steel, alloyed and unalloyed steel, aluminium, nonferrous metals and alloys, structural steel, cast iron, titanium. Minimum order quantity for articles not included in 1036 program: 200 pcs/diameter 115 - 80 pcs/diameter 178

Request for a quote

BIBIELLE S.P.A.

Italy

Particularly robust nylon backing. Overlapped pairs of zirconium flaps and X-weight backing. Only the flat version is available. Main features and benefits: The zirconium abrasive is particularly suitable for applications requiring high operating pressure and even for medium/high-power cornering grinders. The flap paired arrangement provides better ventilation and improves scrap/waste escape. Wide abrasive surface, constant wear, continuous exposure of new grit, high and even cutting performance. Always use the backing pad for the 165mm-diameter disc. Recommended applications: Deburring, removing welding seams, blunting sharp corners and edges. Work surfaces: Stainless steel, alloyed and unalloyed steel, aluminium, nonferrous metals and alloys, structural steel, cast iron, titanium.

Request for a quoteResults for

Aluminium alloy die casting - Import exportNumber of results

43 ProductsCountries

Company type

Category

- Aluminium and aluminium alloys (7)

- Aluminium alloys (6)

- Casting, steel (4)

- Die casting moulds (3)

- Iron, steel and metallurgy - import-export (3)

- Foundries - copper, bronze and brass (2)

- Refrigerants (2)

- Cast iron items (1)

- Fire alarms and detection - equipment and systems (1)

- Foundries, aluminium (1)

- Gas and oil pipelines - installations (1)

- Hand tools, non-power (1)

- Metallurgy and iron and steel industry - machinery and installations (1)

- Steels and metals - forming and cutting (1)

- Steels and metals - welding and brazing (1)

- Surface treatment - machinery and equipment (1)