- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- die casting moulds

Results for

Die casting moulds - Import export

AICS BUSINESS SOLUTIONS CELIK SANAYI VE TIC. LTD. STI.

Turkey

The sand molding process offers a wide range of design options while at the same time making it cheaper and faster. With the molding we can flexibly respond to your needs and offer you the most economical solution. We can supply you parts from 0.1 KG up to 15.000 KG individual weight in the procedure forms Our Aluminum Casting Suppliers for Automotive and Aviation are IATF16949 and EN 9100 certified. Great alloy selection High flexibility Low tooling costs Low production costs steel casting cast iron ductile Iron casting Aluminum Sand Casting Low Pressure Casting

Request for a quote

STEEC

France

Since it was founded in 1979 STEEC offers, has been offering the service of machining parts for moulds and dies for all types of industries based on wire spark erosion cutting in particular. Because of this STEEC is recognized for its expertise in this field of activity both in France and in Europe as a whole.

Request for a quote

MVA D.O.O.

Slovenia

We offer product design consultations, tool designing, mould manufacturing and mould maintenance and service.

Request for a quote

XIAN HUAN-TAI TECHNOLOGY & DEVELOPMENT CO., LTD.

China

Our company (Huan-Tai) is rooted in China since mid-90’s. As one of the early runners, we bring value to the table through our capabilities in engineering, quality control and schedule management that meet the high expectations of overseas customers in stability, consistency and predictability. We focus on quality and consistency. Batch production are always consistent with sample. Our Quality assurance: 1. Non-destructive test (NDT): magnetic particle examination (MPE), ultrasonic examination (UE), liquid penetration examination (LPE), X ray. 2. Experienced inspector on dimensions, CMM dimension testing and other tools. 3. To maintain our reputation, we still have excellent return and claim policy even some rare defects. 4. Our prices are always competitive. 5. Spectrometers to assure the material.

Request for a quote

XIAN HUAN-TAI TECHNOLOGY & DEVELOPMENT CO., LTD.

China

Material: custom size: according to drawings Our company (Huan-Tai) is rooted in China since mid-90’s. As one of the early runners, we bring value to the table through our capabilities in engineering, quality control and schedule management that meet the high expectations of overseas customers in stability, consistency and predictability. We focus on quality and consistency. Batch production are always consistent with sample. Our Quality assurance: 1. Non-destructive test (NDT): magnetic particle examination (MPE), ultrasonic examination (UE), liquid penetration examination (LPE), X ray. 2. Experienced inspector on dimensions, CMM dimension testing and other tools. 3. To maintain our reputation, we still have excellent return and claim policy even some rare defects. 4. Our prices are always competitive. 5. Spectrometers to assure the material.

Request for a quote

MING XIAO MANUFACTURING CO., LTD

China

Ming Xiao Manufacturing Co., Ltd. is a professional ISO9001 certificated Metal Parts & Plastic Parts manufacturer, Located in China Ningbo, Specialized in Services of Sheet Metal Fabricating, CNC Turning & Machining, Tube Bending, Cold Forging & Hot Forging, Plastic Injection Molding & Plastic Extrusion. We outsource aluminum die castings from our friend factory, then do further machining process, finish treatments. sales@mxmparts.com

Request for a quote

MING XIAO MANUFACTURING CO., LTD

China

Ming Xiao Manufacturing Co., Ltd. is a professional ISO9001 certificated Metal Parts & Plastic Parts manufacturer, Located in China Ningbo, Specialized in Services of Sheet Metal Fabricating, CNC Turning & Machining, Tube Bending, Cold Forging & Hot Forging, Plastic Injection Molding & Plastic Extrusion. We outsource aluminum die castings from our friend factory, then do further machining process, finish treatments. sales@mxmparts.com

Request for a quote

PLANSEE SE

Austria

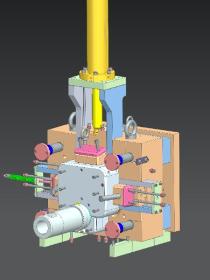

During the aluminum casting process, the metal melt is either poured or pressed into the mold. This process is used, for example, to manufacture cylinder heads, wheel rims and many other aluminum castings. Here, the mold has to repeatedly withstand the metal melt at a temperature of over 600 °C: for inserts made of our tungsten-heavy metal alloy Densimet® and the molybdenum alloy TZM, that's not a problem. The benefits to you: — Shorter cycle times — Top surface quality for your products — Long mold service life — No cracks in the mold insert Tailor-made mold inserts, sprue bushes, cooling inserts and other individual parts as well as semi-finished products for your mold are available.

Request for a quote

EUROBALT ENGINEERING OÜ

Estonia

Metal die casting – is a production technology of castings, in which the alloy under pressure up to 700 MPa quickly fills the mold. Products made in this way can be of different sizes and have weigh up to several kilograms. As a basic raw material normally are used following: non-ferrous metals — copper, aluminum, and their alloys. Die casting makes it possible to obtain high-precision products (along with such technology as powder metallurgy, which allows to obtain sintered metal parts that are particularly hard and wear-resistant). Our company offers the manufacture of parts for LED lighting and other high quality castings. One of the main advantages of die casting is the resistance of finished products to corrosion. The fact is that in the process of their manufacture a strong surface crust is formed, which has a high density and low moisture permeability.

Request for a quote

LBI

France

We manufacture rough or fully machined pouring ladle bushes in high tensile brass

Request for a quote

VLADIMIR PLANT OF RUBBER TECHNICAL INDUSTRY (VLADRTI LLC)

Russia

VladRTI has workshops for industrial rubber goods and metalworking. Our staff is composed of professional employees who are ready to produce any molded RP and design the most efficient mold for this. In this regard, we are always ready to help you and take care of all the nuances of the production of non-standard molded RP. There are two options for the production of molded RP. - the customer has a mold: 1. Based on the product data, we will calculate production cost. 2. We receive the mold and make a test sample (if the mold is not designed correctly and this leads to additional costs, the price is recalculated). 3. The customer should approve the sample (if the sample does not fit, we get feedback on it and make a new one based on additional input. Price changes are possible). 4. We start production of the batch.

Request for a quote

BESTONE TECHNOLOGY LIMITED.

China

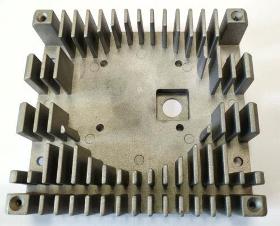

Precision injection tooling-1 cavity side and 3 core side-this is core side-3.

Request for a quote

GRIMM INDUSTRIES PTE LTD

Singapore

OEM Hardware – customised according to your needs

Request for a quote

ANTUNG TRADING CORP. GROUP

Taiwan R.O.C.

Die casting Cover & foot peg

Request for a quote

KAMYANKA MACHINE-BUILDING PLANT

Ukraine

Cast iron: weighing up to 350 kg. Steel: weighing up to 200 kg. Colored: weighing up to 50 kg.

Request for a quote

GPMFG

Canada

We offer top die casting services using 24 machines from 50 to 800 tons, with in-house mold development, machining capabilities, and the latest technology to deliver high quality products and excellent customer service. Products/Parts Analysis & Optimizing Tooling/Molds Development & Manufacturing Aluminum Die Casting Magnesium Die Casting Zinc Die Casting CNC Machining Die-Casting Parts Diverse Post Processes Available GPMFG, a leading China-based die-casting company, employs advanced machinery to create high-quality products worldwide. Our capabilities span various product sizes using hot and cold pressing, achieving precision with thin 0.38mm walls and a surface finish of 0.8-3.2um Ra through high-pressure casting. We also provide additional services like mold making, surface treatment, and component assembly. 800 Tons Of Casting Components Annual Processing Capacity Die Castings From 5g-12kg Production Of Around 100K Components Per Day 24 Die Casting Machines

Request for a quote

HH MOULD CO.,LIMITED

Japan

Die Casting And Stamp Tooling AUTOMOTIVE DIE CASTING Our products Plastic injection molds and products, Die casting molds and Aluminum alloy products. Our Services Design(injection moulds,die casting moulds and products). Manufacturing project manage. Assembly(moulds and products). HH Mould Co., Ltd has 8sets 88T-800T zinc and aluminum alloy die-casting machines with an area of 5800. The company has internal engineering department, mould department, CNC department, die-casting department, finishing and machining department, polishing department, sand blasting and shot blasting department, assembly department, product inspection department and so on. It also has its own electroplating plant, which specializes in providing mold development and design, precision mold making. Manufacturing, die casting, finishing, finishing, polishing, electroplating, fuel injection, powder injection, special anodizing, assembly of finished products and other business.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

YOUNG FOUNDRY - ANATOLIA CASTING

Turkey

Casting iron products, foundry, manhole, gratings, ductile cast iron tree gratings, cast iron castings, contract manufacturing of cast iron casting, outsource for cast iron casting, subcontractor for cast iron casting, drain covers, Casting Channel, polymer Channel, Ductile Iron U Channel Grid for Rainwater System, Ductile Iron Gully Grating, Ductile Iron Channel Grating Water Grates, Cast Iron Sewer Grating for Sewerage System, Ductile Iron Drain Grid, Ductile iron gratings, Ductile Iron Grate and Frame, Cast Iron Drainage Grid EN124, Rain grate, Ductile Iron Locking Grid, sewer cover, DCI Manhole Cover, Ductile Iron Manhole Cover,Square Manhole Cover,Cast Iron Manhole Cover En124 F900 E600 D400 C250 B125 A15, Access Covers, Gully Grates, Kerb Drainage, Surface Boxes, molding etc hs code 732599

Request for a quote

TECHNOCOAT INTERNATIONAL CO., LTD.

Japan

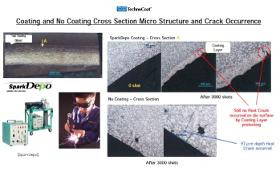

Kaizen!! Most Effective and Cost Reducible Surface Treatment device for Diecasting from Japan! No any heat damages occurred by No Hot procedure! This Kaizen Device Coating is available on Japanese Automotive Company's process sheets and design sheets!! The best way for Costs Reducing!!

Request for a quote

XIAMEN NINESUN IMP. & EXP. CO., LTD

China

Application SMT, BGA, CSP, Flip Chip, LED Detection, Semiconductor, Packaging components, Battery Industry, Electronic components, Automotive parts, Photo-voltaic, Aluminium Die-casting, Moulding Plastic. Ceramics, other special industries.

Request for a quote

ZS INDUSTRIES CO., LTD

China

Material:Grey Iron: GG15, GG20, GG25, GG30 Ductile Iron: GGG40, GGG45, GGG50, GGG60, GGG70 Process: Resin sand casting, Film-covering sand casting, Clay sand casting, Hand molding and machine molding Application: Agricultural machinery, Off-shore industry, Printing machinery, Waste treatment machinery, Concrete plant equipment, Packaging machinery, Pumps

Request for a quote

SUN CHEMICAL - COLORS & EFFECTS NETHERLANDS B.V

Netherlands

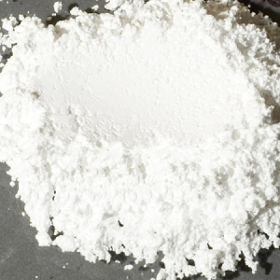

Lithium Carbonate is a special use chemical used in the steel industry. It serves as a moulding powder when casting steels. It is also usable in the health industry for the treatment of specific diseases. Likewise, the chemical finds application in the glass-making industry. You can extract lithium from a brine pool (underground). Lithium Carbonate is a natural chemical in lakes and seas. The chemical formula is Li2CO3.

Request for a quote

ALWA TECHNISCHE PRODUKTE FÜR KUNSTSTOFFVERARBEITUNG, MODELL UND FORMBAU GMBH

Germany

Together with the Fachhochschule Münster – University of Applied Sciences we are working on ALWA PERM (patent No. 2583995). This is a metal-filled casting resin for producing a porous, resin-bound mould. These materials are applicable in the areas of thermoforming, the ceramic industry, intake moulds and devices, pneumatic cushioning, the filter industry, etc. ALWA PERM allows a castable production of porous metallic materials with a binder for the first time. The system offers a highly accurate mould surface reproduction. The profile characteristics goes far beyond the current state of the art. NO MORE DRILLING OF VACUUM HOLES! NO DAMAGE OF THE MOULD SURFACE DUE TO DRILLING HOLES

Request for a quote

ALWA TECHNISCHE PRODUKTE FÜR KUNSTSTOFFVERARBEITUNG, MODELL UND FORMBAU GMBH

Germany

The patented casting resin system ALWA MOULD D consists of two resin components and an aluminium filler. The fast curing of the material allows to produce your own technologically highest quality moulds in just a few hours. As our material is very good castable, compact moulds of any desired volume can be made from our product, such as acrylic baths, boats, etc. (<1 kg – 2500 kg). In comparison to other materials (e.g., glass fibre reinforced plastic), the system is more temperature-resistant, allows castings without air bubbles and does not have to be post-cured. Furthermore, the finished mould is easy machinable (e.g., drilling, milling, grinding, planning, sawing, turning, etc.). ALWA MOULD D moulds can be modified with repair filler, so that a fresh view can be created at an early stage of a new design process and prototypes can be examined at short notice.

Request for a quote

ALWA TECHNISCHE PRODUKTE FÜR KUNSTSTOFFVERARBEITUNG, MODELL UND FORMBAU GMBH

Germany

ALWA repair filler (art. no. 5100001) is used in order to repair casting resin moulds. The filler is mixed with 1 – 3 % hardener powder.

Request for a quote

ALWA TECHNISCHE PRODUKTE FÜR KUNSTSTOFFVERARBEITUNG, MODELL UND FORMBAU GMBH

Germany

Aluminium perforated sheets are used in order to reinforce the casting resin moulds.

Request for a quote

ALWA TECHNISCHE PRODUKTE FÜR KUNSTSTOFFVERARBEITUNG, MODELL UND FORMBAU GMBH

Germany

ALWA MOULD SLV is a universal two-component fast casting PU resin for mould making. It is used for the production of milling devices, negatives, product holders, foundry moulds, mould plates, copy moulds, core boxes, pattern plates, casting moulds, prototype parts, supporting moulds and synthetic cast. It consists of a beige-brown low viscosity resin component A (polyol mixture) and a red-brown, low viscosity hardener (component B) based on isocyanate (Methylendi(phenylisocyanat)e = MDI). Two types are available with different pot life: *ALWA MOULD SLV 3 ~ 3 min. pot life *ALWA MOULD SLV 9 ~ 9 min. pot life

Request for a quote

ALWA TECHNISCHE PRODUKTE FÜR KUNSTSTOFFVERARBEITUNG, MODELL UND FORMBAU GMBH

Germany

Silicone rubber ALWA SIL SH 22 and SH 33 are silicone impression materials. These materials have extremely high mechanical values. In addition, they are very fast to handle and very easy to handle as well. The two-component silicone rubbers cure at room temperature. After mixing the two components, a low viscosity liquid develops, which crosslinks to a resistant and rubber elastic material. During the crosslinking, no exothermic heat is developed. When 1 – 3 % thixotropic agent is added per component, a spreadable mixture is obtained. Area of application: *Flexible casting moulds *Copy moulds *Moulds with undercuts *Polyurethane casting moulds *Concrete casting moulds

Request for a quote

ALWA TECHNISCHE PRODUKTE FÜR KUNSTSTOFFVERARBEITUNG, MODELL UND FORMBAU GMBH

Germany

ALWA HT RESIN is a resin-based on isocyanate and epoxy (EP), which reacts after adding a catalyst. ALWA HT RESIN offers a range of possibilities for producers of fibre-reinforced materials (e.g., glass fibre, kevlar and carbon), semi-finished and finished goods. The system is also suitable for prepreg and reaction compounds. ALWA HT RESIN is particularly interesting for the aerospace and aircraft industry as well for the rail transport, automotive and electronics industry. The application area of epic resins are electro casting resins, lamination and injection technology (RTM procedure), vacuum infusion, casting and ramming compounds, impregnation resin, casting and injection moulding process as well as prepreg technologies, among others. ALWA HT RESIN is offered in two versions. *ALWA HT RESIN M100 with approx. 50 mPa s *ALWA HT RESIN M2200 with approx. 2200 mPa s The resins can be mixed with one another which enables a flexible adjustment of the viscosity.

Request for a quoteResults for

Die casting moulds - Import exportNumber of results

57 ProductsCountries

Category

- Die casting moulds (20)

- Copper and copper alloys (7)

- Casting, steel (5)

- Cast iron items (3)

- Copper sheets and bands (3)

- Lead sheets and bands (3)

- CAD/CAM Computer Assisted Design/Computer Assisted Manufacturing - software (1)

- Chemical catalysts (1)

- Copper wires and cables (1)

- Foundries - copper, bronze and brass (1)

- Foundries - machinery and installations (1)

- Iron and steel industry and foundries - machinery and installations (1)

- Lead and lead alloys (1)

- Metallurgy - machinery and installations (1)

- Moulds, foundry (1)

- Portable electrical pumps (1)

- Precision mechanics (1)

- Roadlaying materials (1)

- Rubber products (1)

- Silicones (1)