- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- gas nozzles

Results for

Gas nozzles - Import export

ALPHA LASER GMBH

Germany

You won’t get it more flexible. The mobile welding laser AL-ARM was developed to quickly and flexibly repair offset seams, pores and penetrations in the car body. The fiber laser system can be positioned quickly and has a long range. The 3D visualization with integrated laser safety glasses enables the user to observe his welding task as well as the surroundings. The welding process is shown enlarged and the process-relevant data is also visible in the image. The handpiece, which is used for welding, is equipped with an automated wire feed and an integrated shielding gas nozzle. It weighs just 1.5 kg and is easy to position. There is no set-up time for welding.

Request for a quote

OKS SPEZIALSCHMIERSTOFFE GMBH

Germany

Mould parting agent for entire range of plastics processing if an adhesion-dependent further processing requiring silicone-free parting agent is carried out Welding parting agent for arc welding and inert-gas arc welding As nozzle spray for extended service life of welding nozzle and keeping nozzle opening clear on automatic welding units As workpiece protection against baking and burning on of weld spatters Advantages and benefits Silicone free release agent with high effective substances from renewable primary products Prevents from burning in of spatters at welding nozzles, on workpieces and robots and increases the lifetime of the welding torch Builts up an evenly thin, nearly dry film, no creation of pores Enables the fast change and cleaning of the welding nozzle Easily washable with OKS 2650 Additional painting, metallising and printing after prior degreasing without any difficulties possible

Request for a quote

OKS SPEZIALSCHMIERSTOFFE GMBH

Germany

Protection of surfaces of all kinds and welding nozzles for oxyacetylene gas and inert-gas arc welding Prevents baking on of weld spatters on surface and welding nozzle Advantages and benefits Later painting over, metallising and printing following prior cleaning easily possible Environmentally friendly, non-combustible Silicone-free Can be removed residue-free OKS 1600 is also suitable for use with the refillable Airspray system Also available as spray version OKS 1601

Request for a quote

OKS SPEZIALSCHMIERSTOFFE GMBH

Germany

Protection of surfaces of all kinds and welding nozzles for oxyacetylene gas and inert-gas arc welding Prevents baking on of weld spatters on surface and welding nozzle Advantages and benefits Later painting over, metallising and printing following prior cleaning easily possible Environmentally friendly, non-combustible Silicone-free Can be removed residue-free

Request for a quote

OKS SPEZIALSCHMIERSTOFFE GMBH

Germany

Mould parting agent for entire range of plastics processing if an adhesion-dependent further processing requiring silicone-free parting agent is carried out Welding parting agent for arc welding and inert-gas arc welding As nozzle spray for extended service life of welding nozzle and keeping nozzle opening clear on automatic welding units As workpiece protection against baking and burning on of weld spatters Advantages and benefits Silicone free release agent with high effective substances from renewable primary products Prevents from burning in of spatters at welding nozzles, on workpieces and robots and increases the lifetime of the welding torch Builts up an evenly thin, nearly dry film, no creation of pores Enables the fast change and cleaning of the welding nozzle Easily washable with OKS 2650 Additional painting, metallising and printing after prior degreasing without any difficulties possible

Request for a quote

NOVELTY STEEL

Turkey

Plasma cutting operates by firing an electrically ionised heated gas (plasma) out of a nozzle at a high speed towards the metal. This will form an electrical ark within the gas. High level of heat is generated as electricity from the nozzle travels down this plasma. This heat melts the metal where cutting is achieved. Plasma cutters can cut stainless steel, aluminium, brass and copper along with mild steel. It’s particularly ideal for thick metal, up to 50 mm. If cutting highly reflective or very thick sheets of metal is required, plasma should be the ideal cutting method. Our modern steelwork fabrication shops have computer-aided design and detailing (CAD), which is linked directly to factory floor computer numerically controlled (CNC) machinery, creating a genuine seamless CAD/CAM environment. Novelty Steel has adapted EN 1090-2 standards into its manufacturing processes supervised by experienced quality management team.

Request for a quote

PEMAT S.C.

Poland

KIT SPARE PARTS FOR MIG WELDING TORCH MB15 - 20 PIECES KIT EQUIPMENT: Gas nozzle MB-15 - 4 pcs. Contact tip M6x25mm 0.8mm - 10 pcs. Tip holder with spring - 2 pcs Plastic insulator - 2 pcs. Spring - 2 pcs. 1. GAS NOZZLE (SCALE) Length: 53 mm Wed External basics : 18 mm Wed Outlet ext. : 12 mm 2. CONTACT TIP Hole diameter: Φ0.8mm Thread: M6 Length: 25mm 3. TIP HOLDER WITH SPRING Length: 42mm Thread for contact tip: M6 Torch mounting side thread: M8x1 left-hand thread 4. INSULATOR / SLEEVE PLASTIC

Request for a quote

BASAK LAZER

Turkey

Argon welding is the word “Tungsten Inert Gas” that gives the welding method its name. Welding is also called the initials of this word and is referred to as TIG welding. The heat to perform the welding process is generated between the electrodes made of tungsten metal, which has a very high melting point, and the parts to be welded. The welding zone is protected by argon or helium gas sent from a nozzle surrounding the electrode. The electrodes used in the Tig (argon) welding method allow to join the welded material by melting, without melting themselves. When deemed necessary, additional welding rods are delivered to the welding area by the welder or by automatic wire feeding devices, as in oxy gas welding. Argon gas is generally used as a shield in argon welding. Argon gas is a noble gas, so it does not react and provides strong protection. It optimizes the ignition characteristics and stability of the arc

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

BN is a material with non-wet feature. So molten metal won’t be sticked onto the nozzle. Additionally, Boron Nitride ceramic is a kind of refractory ceramic with low expansion and high thermal conductivity. These features make it to be an ideal choice as atomizing nozzles. It's very easy to be machined to custom design with precision and tight tolerance because of its machinability. Boron Nitride Ceramic BN Nozzles Performance: 1.The optimized formula and unigque process make it highly resistant to thermal shock and high-temperature creep.Maximum using temperature 1700°C. 2.Low thermal expansion coefficient,no cracking or deformation during use. 3.Strong erosion resistance,wear resistance and metal corrosion resitance.Long service life. 4.Good raw materials,process control,product stability. 5. It is used in Amorphous Ribbon Making and amorphous nozzles.

Request for a quote

GLOBAL GASES GROUP THAI CO LTD

Thailand

Fast Gas Cream Charger Cylinders Introducing the Fast Gas Nitrous Oxide cylinder the new and improved cream charger system which connects easily to your cream dispenser with a pressure adapter. Please note you should only use 500ml Metal Head dispensers or Stainless Steel Cream Dispensers with the Fast Gas system. Each tank contains up to 640g of high-quality food grade nitrous oxide, with purity of up to 99.9%. The Fast Gas system makes creating innovative food and beverages easy with the click of the connector hose to your dispenser whip up a treat in no time at all with no waste from each capsule. The cylinders are suitable for recycling once fully empty. You will receive a pressure release nozzle with each tank, the nozzle will allow you to be sure the tank is empty prior to recycling due to safety reasons. Please check with your local recycling authority prior to disposing. OVER 18’s ONLY: This product is not for sale to under 18’s.

Request for a quote

EWM AG

Germany

TIG welding torches, gas- or water-cooled from 150 A (gas-cooled) up to 400 A (water-cooled). — TIG welding torch with a highly flexible hose package — Ergonomic GRIP handle for a secure hold and ergonomic use — Excellent HF reliability — Ready to weld with tungsten electrode, gas nozzle and back cap

Request for a quote

K-TECH ELECTRONIC VERTRIEBS GMBH

Germany

In contrast to chamber devices, the vacuum sealer AZ450 from AIRZERO works with a suction nozzle. This principle offers advantages Since only the bag and not the entire chamber is emptied, the process is faster. Lower gas consumption when gassing (only the bag is gassed and not the entire chamber). The gas is blown into the bag in a targeted and controlled manner. No limitation of the bag length by the chamber. Bar goods can therefore also be processed. Compact desktop device. double sealing (up/down) ejektor vakuum pump (air pressure required) gas flushing digital vakuum display 4 programms can be saved housing of stainless steel

Request for a quote

EUROPEM

Belgium

Industries will generate Low CV waste gases, which are either difficult to burn or can contain insufficient energy to self-sustain the combustion process. For these applications, Europem developed the proprietary “ring-of-fire” Flare Tip. This tip has a ring of flame around the central waste gas tip thus ensuring complete oxidation of the low calorific waste gas. Both air assisted and non-assisted flare burners are available. Key features Proprietary design of HP sonic gas nozzle which maximises the entrainment of ambient air into the combustion zone Wind shield placed around the HP gas nozzles to prevent flame pull down Use of high grade alloys to enhance lifetime of the flare tip. Key advantages Smokeless operation at low heat radiation 100% smokeless turn down possible for air assisted HP flares Lower flare stack heights No need for any assist medium A low pressure flare can be integrated with the HP sonic flare to provide both HP and LP gas flaring in a single flare tip. Suitable for smokeless combustion of waste gas with entrained liquids Applications Upstream oil & gas sector Chemical and petrochemical industries including refineries Pipeline transport LNG and NG terminals and compressor stations

Request for a quote

EUROPEM

Belgium

High Pressure Flares use the actual pressure of the waste gas to create turbulence, entraining combustion air into the base of the flame to obtain smokeless combustion. Europem has a full range of high pressure flares including HP pipe fares, sonic flares and HP assisted flares. HP sonic flares are the ideal solution when low radiation along with smokeless operation are desired. Key features Proprietary design of HP sonic gas nozzle which maximises the entrainment of ambient air into the combustion zone Wind shield placed around the HP gas nozzles to prevent flame pull down Use of high grade alloys to enhance lifetime of the flare tip. Key advantages Smokeless operation at low heat radiation 100% smokeless turn down possible for air assisted HP flares Lower flare stack heights No need for any assist medium A low pressure flare can be integrated with the HP sonic flare to provide both HP and LP gas flaring in a single flare tip. Suitable for smokeless combustion of waste gas with entrained liquids Applications Upstream oil & gas sector Chemical and petrochemical industries including refineries Pipeline transport LNG and NG terminals and compressor stations

Request for a quote

EUROPEM

Belgium

In cases where waste liquid’s or suspension’s need to be incinerated, EUROPEM uses liquid fuel injection lances equipped with ultrasonic atomisation nozzles, resulting in very fine droplets and an almost gas-like combustion process. This nozzle uses an atomizing fluid such as superheated LP steam or compressed air. EUROPEM Natural Draft and Forced Draft Burners Different configurations for the atomization nozzle are possible, depending on the burner design, capacity range and the desired spray pattern in relation to the combustion chamber. The nozzle operates based on the Hartmann Generator principle and was originally developed the early 1970s. In 2007, the nozzle was optimized and now has a fuel turndown ratio of 10:1. Hartmann Generator principle: Through a jet nozzle (D), a gaseous fluid flows with supercritical pressure ratio – meaning sonic speed. According to Mach and Salcher a periodical structure will build up in the stream (dotted line). Graph K shows the pressure cycles along the length of the gas stream. Oscillations occur by filling (pressurizing) and deflating the hollow space H. This is the principle used for the Ultrasonic Nozzle. A Hartmann Generator is placed as a concentric ring around a central liquid fuel pipe. The high exit speed of the atomizing fluid (compressed air, steam or combustible gas) alone achieves a rough atomization, caused by the negative pressure. The ultrasonic effect created by the Hartmann Generator oscillates the pre-atomized droplets at a high frequency, and further fragments the droplets into a very fine mist. Advantages: Low and high viscosity fluids are atomized into smallest possible droplets. No limitation on ash content and other solid particles in liquid fuels. Various fuel types can be used in one nozzle, no limitation on fuel mixtures. High durability due to low operating pressure for fuel and atomizer. Different nozzle types to obtain different spraying paterns

Request for a quote

EP EHRLER PRÜFTECHNIK ENGINEERING GMBH

Germany

The test bench is designed for calibration with critically operated nozzles of domestic gas meters or others such as diaphragm gas meters, ultrasonic meters, thermoelectric gas meters. The test bench is specially designed for the calibration of domestic gas meters (bellows gas meters, ultrasonic meters, thermoelectric gas meters). The test bench is modular - 1x6 to 4x6 clamping positions for the gas meters can be combined. Due to the modular design 1 to 12 gas meters can be tested simultaneously. In parallel, up to twelve additional test pieces can be adapted, run in and leak tested. A magazine consisting of three critical nozzles is used as flow transmitter. Optionally, a nozzle drum with nine combinable nozzles can be used. This allows the generation of up to 512 different flow points with highest accuracy.

Request for a quote

IGM ROBOTERSYSTEME AG

Austria

igm gas nozzle searching - Tactile sensor for position detection This tactile sensor is used to determine the workpiece position or its components and individual parts by gauging the surface of the workpiece. In each case, the successional part of the program is shifted according to determined deviations. Sensor shifting may be applied for correction of an arbitrary amount of individual points, entire sections of a welding program or entire programs. Combination with arc seam sensing is feasible. The control system supports shifting, rotating, and tilting of a program, depending on position change. The gas nozzle itself is used as a sensor. This makes it possible - even on complicated workpieces and in confined spaces - to perform the required search steps on the reference surfaces of the workpiece, by which the position of the weld seams is determined. As soon as the gas nozzle gets into contact with the work piece, it is discharged and the robot stops immediately. This...

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

S.C. SERE TRANSILVANIA S.A.

Romania

The gas heaters are specially designed for the corrosive environment inside greenhouses and tunnels. These are machineries used by professionals in order to obtain the ideal climate for the crops. One may chose between nozzles for natural gas or for propane (GPL). The air admission is made from the exterior. The evacuation of the burnt gases is made through a stainless steel exhaustion system. A thermostat can be equipped on each device in order to regulate the needed temperature. For a more efficient use of the gas heaters, it is recommended to destratify the air inside the greenhouse using recirculation fans. Advantages: - the most efficient means of heating the greenhouse - the possibility of setting the necessary temperature - reduced maintenance costs - relatively low installation costs - zero operation costs (automation) The heater has additional accessories that can be viewed on our website, as well as other types of heating systems.

Request for a quote

THIELMANN ENERGIETECHNIK GMBH

Germany

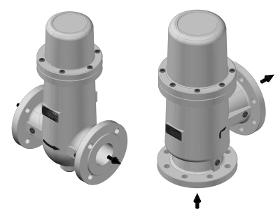

CHARACTERISTICS Efficient dust filtration High deposition rate (efficiency) Filter efficiency tested acc. SAE Fine Test Long service life of the filter elements Upstream coarse particle separation For all gases according to G260 For non-aggressive special gases OPTIONEN Customer-specific design for other regulations (ASME, EN 13445, SVTI, AS1210, PD5500, etc) Customer-specific approvals Customer-specific testings Application for sour gas (NACE) Design for low temperature down to -50 ° C Design pressure up to 300 bar Design temperature up to 250 ° C Customer-specific nozzle arrangement Leaflet (english version in progress): D-5025 Patronenfilter / Typ VPF General Cartridge filters are used to clean gas from dry solid dust particles. The design is carried out as a steel welded construction. FUNCTION The gas flows through the inlet nozzle into the filter housing.

Request for a quote

THIELMANN ENERGIETECHNIK GMBH

Germany

CHARACTERISTICS budget priced short installation length type VZF and ZFG high filtration rate (efficiency) replacable filter cartridges large dust collection area VZF / ZFG dust drain nozzle N3 upstream coarse particle separation 4-way differential pressure connections DVGW certified for all gases according to G260 for non-aggressive special gases many sizes in stock VARIANTS Silumin Cast (VZF/VZEF) Cast Iron (ZFG/ZEFG) Straight Through – VZF/ZFG | DN25 – DN150 Corner Type – VZEF/ZEFG | DN25 – DN100 PN16 | -10 / +70 °C PN16 | -20 / +70 °C PN16 | -40 / +70 °C PN16 | -10 / +150 °C zzgl. TÜV HTB (5 bar g) | -20 / +70°C PN40 | -10 / +70 °C DN25-DN80 PN40 | -20 / +70 °C DN25-DN80 PN40 | -40 / +70 °C DN25-DN80 DNV (maritime) DN25 – DN100, 10 bar g | 0 /+60°C Leaflet: E-5055 Cellular Gas Filter / Type VZF/VZEF/ZFG/ZEFG FUNCTION The gas flows through the inlet nozzle into the filter housing.

Request for a quote

A YANGIN GUVENLIK SIST. SAN. VE TIC. A.S.

Turkey

Automatic detection and activation management provides 24 hours protection. In addition of fire detection, you can activate the system manually thanks to a special system of manual activation. The most effective agent in fire extinguishing industry. Thanks to high pH formula it extinguishes fire and prevents reignition. Steel cylinders under pressure are always ready to discharge the fire extinguishing agent in case of fire. Pressure transducer on the cylinder of fire extinguishing agent provides visual control. 100 % installed and tested control block ensures safe operation of the input and output functions. Installation will be made without disturbing the workflow of your kitchen due to the flexible pipe configuration. Protective chrome cover protects nozzle from clogging by dirt and grease, providing discharge of gas without interruption. Nozzles’ cover are removing and don’t interrupt the discharge of fire extinguisher.

Request for a quoteResults for

Gas nozzles - Import exportNumber of results

22 ProductsCountries

Company type

Category

- Silicones (4)

- Welding work - steels and metal (2)

- Calibration equipment (1)

- Ceramics, industrial (1)

- Fire protection services (1)

- Gases, compressed and liquefied (1)

- Ice cream-making - machinery and equipment (1)

- Industrial sheet metal work (1)

- Laser - cutting and welding machines (1)

- Packing and packaging - machinery and equipment (1)

- Unit heaters (1)