- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- mining and quarrying - machinery and equipment

Results for

Mining and quarrying - machinery and equipment - Import export

ZWP ZAHNRADWERK PRITZWALK GMBH

Germany

ZWP is one of Germany’s largest independent gear, pinion and shaft manufacturers. We manufacture according to customer drawings and supply renowned customers from a wide variety of industries. We also supply renowned customers on an international level with our products for mining technology. Here is an overview of our production possibilities: Internal toothed rings hardened and grinded Module up to 20 mm Diameter 100 to 1,800mm Gears internal and external toothed hardened and grinded Module 2 – 50 mm Diameter 100 – 2,000 mm Interlocking shafts internal and external toothed hardened and grinded Module 1 – 50 mm Diameter 50 – 500 mm Length up to 1,500 mm Hardening and balancing inhouse possible We manufacture for different customers: mining, rail, wind power, shipping, industry and special machinery. Production is carried out according to customer drawings and standards. Further information in the first interview. We look forward hearing from you.

Request for a quote

ZWP ZAHNRADWERK PRITZWALK GMBH

Germany

ZWP is one of the leading independent manufacturer in Germany for gears, pinions and rim gears. We supply already well-known manufacturers for gear boxes, drive technology and are looking forward to new customers. Sectors of our (international) customers are: Mining, Oil, Offshore, rail and ship transmissions, industrial transmissions, and many more fields of applications. Overview about the capabilities for production: Gears internal and external toothed hardened and grinded Module 2 – 50 mm Diameter 100 – 2,000 mm Internal toothed rings / rim gears hardened and grinded Module up to 20 mm - more on request Diameter 100 to 1,800mm Pinions and shafts internal and external toothed hardened and grinded Module 1 – 50 mm Diameter 50 – 500 mm Length up to 1,500 mm Hardening and balancing inhouse possible Cooperation with companies for special manufacturing of gears and pinions etc We speak English. ZWP is looking forward hearing from you.

Request for a quote

NOVELTY STEEL

Turkey

A screw feeder is primarily designed for handling very low-tonnage outputs, with a critical requirement for positive and controlled material discharge. This type of feeder offers the advantage of easy enclosure, making it effective at preventing the release of dust. Consequently, it allows for a sealed hopper and chute arrangement from the hopper to the delivery point. The basic structure of a screw feeder includes a helical screw that rotates below the hopper outlet and is driven by an external power source. The screw can have a fixed pitch or a variable pitch with smaller spacings in the rear and gradual increases in pitch towards the discharge end. This design ensures that the material moves efficiently within the rear portion of the hopper. Novelty Structures supplies various type of Feeders for Mineral Processing Plants. * Belt Feeders * Screw Feeders * Apron Feeders * Rotary Table Feeders

Request for a quote

NOVELTY STEEL

Turkey

A belt feeder is comprised of an uninterrupted rubber belt that is supported by closely spaced idlers and propelled by end pulleys, commonly known as the head and tail pulleys. This entire assembly is enclosed within a single framework. The motor can be installed on the ground or on a separate frame and drive the feeder through the use of V-belts. Typically, the belt feeder is positioned beneath a hopper with a long, narrow slot-like opening. It allows the material to be fed along the length of the hopper. Belt feeders typically come in a range of widths from 0.6 to 1.8 meters and lengths spanning from 1.5 to 4.6 meters. The capacity of a belt feeder is determined by the width of the belt and the speed at which it moves. In practice, the capacity of belt feeders generally falls within the range of 4.5 to 2,270 tons per hour. Novelty Structures supplies various type of Feeders for Mineral Processing Plants.

Request for a quote

ZWP ZAHNRADWERK PRITZWALK GMBH

Germany

ZWP is one of the leading independent manufacturer in Germany for gears, pinions and ring gears. We supply already well-known manufacturers for gear boxes, drive technology and are looking forward to new customers. Sectors of our (international) customers are: Mining, Oil, Offshore, rail and ship transmissions, industrial transmissions, and many more fields of applications. Overview about the capabilities for production: Gears internal and external toothed hardened and grinded Module 2 – 50 mm Diameter 100 – 2,000 mm Internal toothed rings / ring gears hardened and grinded Module up to 20 mm - more on request Diameter 100 to 1,800mm Pinions and shafts internal and external toothed hardened and grinded Module 1 – 50 mm Diameter 50 – 500 mm Length up to 1,500 mm Hardening and balancing inhouse possible Cooperation with companies for special manufacturing of gears and pinions etc We speak English. ZWP is looking forward hearing from you.

Request for a quote

NOVELTY STEEL

Turkey

The distinctions among various jig types is related to the methods employed for generating pulsation and the manner in which the heavy fraction is extracted from the jig. The screen’s role is to provide support to the particle bed, and the space beneath it is referred to as the hutch. Typically, the tank is divided into two primary sections: one housing the support screen with the ore bed and another responsible for generating the fluid flow. The heavy discharge from the jig can exit in two ways: either passing through the screen or flowing over the screen. When employing jigging through the screen, every particle in the input is smaller than the screen openings, allowing them to potentially fall through the screen and gather in the hutch. Novelty Structures supplies Mining Jigs for various materials.

Request for a quote

NOVELTY STEEL

Turkey

Various minerals are found in nature either in a dispersed state, where they exist as separate entities, such as native gold particles in silica rock, or in a combined form, where they are bound within a host rock. Dry material separations using screens and sieves are typically attempted down to particle sizes of about 75 microns. Finer materials have a tendency to block the sieve openings. In such cases, screening in the presence of water can be helpful. Separating even finer-sized materials becomes challenging using traditional sieves. For such fine materials, alternative processes like classification need to be employed. Screen Types: * Grizzly Screens * Inclined Vibrating Screens * Horizontal Vibrating Screens * Dewatering Vibrating Screens Novelty Structures supplies various type of Screens for Mineral Processing Plants.

Request for a quote

MPN - MECÂNICA DE PRECISÃO DO NORTE, LDA.

Portugal

DESIGN - MANUFACTURE - INSTALLATION - COMMISSIONING COMPLETE INSTALLATIONS MINING - QUARRYING - RECYCLING

Request for a quote

XIAN HUAN-TAI TECHNOLOGY & DEVELOPMENT CO., LTD.

China

We focus on quality and consistency. Batch production are always consistent with sample. Our Quality assurance: 1. Non-destructive test (NDT): magnetic particle examination (MPE), ultrasonic examination (UE), liquid penetration examination (LPE), X ray. 2. Experienced inspector on dimensions, CMM dimension testing and other tools. 3. To maintain our reputation, we still have excellent return and claim policy even some rare defects. 4. Our prices are always competitive. 5. Spectrometers to assure the material.

Request for a quote

XIAN HUAN-TAI TECHNOLOGY & DEVELOPMENT CO., LTD.

China

Liner plates for jaw crusher, crusher parts wear resistant plates Xian Huan-Tai has been specialized in Custom heavy castings with machining include mantle, bowl liner, jaw plates, cone castings etc since 1996. Material options are carbon steel, stainless steel, gray iron, ductile iron, copper etc. to accommodate with different environment. Process include sand castings and vacuum castings. Our inspection: 1.Metal testing and analysis, mechanical properties, microstructure, spectrometer and furnace chemical composition analysis. 2.Non-destruction inspection: MPE, LPE, UE and RE 3.Dimension inspection: well experienced inspector team 4.Quality control 5.3rd party inspection 6.Special inspection method agreed by customers like hydraulic, pneumatic test, water tight test etc.

Request for a quote

XIAN HUAN-TAI TECHNOLOGY & DEVELOPMENT CO., LTD.

China

Xian Huan-Tai has been specialized in Custom heavy castings for cone crusher, jaw crusher include bowl liner, mantle, jaw plates, cone casting since 1996. Material options are carbon steel, stainless steel, gray iron, ductile iron, copper etc. to accommodate with different environment. Process include investment castings, sand castings and lost foam castings. Our inspection: 1.Metal testing and analysis, mechanical properties, microstructure, spectrometer and furnace chemical composition analysis. 2.Non-destruction inspection: MPE, LPE, UE and RE 3.Dimension inspection: well experienced inspector team 4.Quality control 5.3rd party inspection 6.Special inspection method agreed by customers like hydraulic, pneumatic test, water tight test etc.

Request for a quote

XIAN HUAN-TAI TECHNOLOGY & DEVELOPMENT CO., LTD.

China

We focus on quality and consistency. Batch production are always consistent with sample. Our Quality assurance: 1. Non-destructive test (NDT): magnetic particle examination (MPE), ultrasonic examination (UE), liquid penetration examination (LPE), X ray. 2. Experienced inspector on dimensions, CMM dimension testing and other tools. 3. To maintain our reputation, we still have excellent return and claim policy even some rare defects. 4. Our prices are always competitive. 5. Spectrometers to assure the material.

Request for a quote

CARBOMECH SP. Z O.O.

Poland

Pallet has been designed for transportation of various electrical devices as well as other machinery and equipment by means of tracks of suspended monorails operating in underground mining facilities, in both non-methane and methane fields. The pallet is to be assembled in transportation sets of equipment transportation units driven by self-braking shifting devices. It may also be coupled directly or in a transportation set with a diesel locomotive, a handling trolley and another driving unit admitted to operation in underground mining facilities.

Request for a quote

CARBOMECH SP. Z O.O.

Poland

Type 3-201 to 3-212 shaft cable clamps made of stainless steel are used to mount cables in mine shafts, and they have been designed for application in both non-methane and methane fields of underground mining facilities. A prerequisite of correct operation of self-locking clamps is the appropriate clamp choice depending on the cable diameter as well as proper setting of the cable clamping jaws. Type 3-201 to 3-212 clamps are available in an option enabling shaft bracket mounting.

Request for a quote

CARBOMECH SP. Z O.O.

Poland

The hydraulic unit is designed to power the self-locking shifting device as well as to power other devices and machines with hydraulic drive. The unit can be operated in underground mines in non-methane and methane fields, in workings classified as "a", "b" or "c" of methane explosion hazard and in workings classified as class "A" or "B" coal dust explosion hazard.

Request for a quote

CARBOMECH SP. Z O.O.

Poland

People's platforms are designed to enable safe boarding or alighting on or off the conveyor belt while transporting people by belt conveyors. The platforms are adapted to be installed on belt conveyors of any parameters. Additionally, with the platforms, a structure is used to install limit switches, sensors and elements of electrical equipment necessary to maintain safety.

Request for a quote

CARBOMECH SP. Z O.O.

Poland

The driving unit of the type 20-101-105 is a traction device designed to push or pull transportation trains on overhead monorails with the cross-section profiles of I-155, I140E or 140V. Typical applications include traction of energy trains with electric equipment, dust extraction appliances, cooling systems, etc. that are moved in pace with the coal face advance. The unit can be operated on running monorails made up of rails with the maximum longitudinal load to rail joints of 60 kN. The driving unit are installed in underground mines, in methane and non-methane areas.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

CARBOMECH SP. Z O.O.

Poland

The device for unwinding the conveyor belt type 12-180 (version I) is designed to unwind a 1400 mm wide conveyor belt from winding drums to the excavation floor. The device is intended for use in underground workings of mining plants, in non-methane and methane fields, in workings classified as "a", "b" or "c" of methane explosion hazard and in workings classified as class A or B of coal dust explosion hazard.

Request for a quote

CARBOMECH SP. Z O.O.

Poland

The light track is designed for manual transport with the use of R-150 or R-250 type trolleys with immediate braking, working individually or in sets (two trolleys connected by a 1400 mm long bar). The light runway can also be used to move a bundle of cables and electric or hydraulic lines suspended on trolleys type 1-604. Elements of the light runway may be used in underground mine workings, in non-methane and methane fields, in workings classified as "a", "b" or "c" methane explosion hazard and class A or B coal dust explosion hazard.

Request for a quote

CARBOMECH SP. Z O.O.

Poland

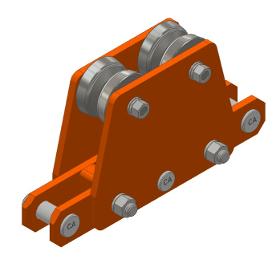

A manually operated trolley with immediate braking is designed for the transport of loads up to 150 and 250 kg, respectively, on the tracks of horizontally built suspended monorails. In the case of transporting long elements, a system of two trolleys connected by a folding rod can be used. The trolley can be used in underground mining plants, in non-methane and methane fields, in workings classified as "a", "b", or "c" of methane explosion hazard and in workings classified as class A or B of coal dust explosion hazard.

Request for a quote

CARBOMECH SP. Z O.O.

Poland

A transport trolley with a cable drum, type 12-156, is intended for the transport of ropes, cables and electric wires in mining excavations. The type 12-156 transport vehicle was made in two construction variants: 1. Version 12-156 - trolley with a drum frame with bearings, enabling 360 degrees rotation around the axis. Placing the drum frame on a ball bearing allows it to be rotated in the direction needed to stretch the cable or rope and to unwind it freely. 2. Version 12-156.1 - a trolley with a fixed drum frame, without the possibility of rotation. A transport trolley with a cable drum is adapted for transport on mine tracks with a rail spacing of 550 ÷ 900 mm. The construction of the cable drum allows it to be removed from the transport car and suspended under the transport set of the suspended railway.

Request for a quote

CARBOMECH SP. Z O.O.

Poland

The CP-20 belt link is intended for connecting trolleys for the transport of electric cables and wires as well as hydraulic lines. Single-layer belt slings type ZP 7.5 is intended for suspending and lifting loads, e.g. in transport sets of suspended monorails, loading hoists, etc.

Request for a quote

CARBOMECH SP. Z O.O.

Poland

Trolleys are intended for transporting loads on the tracks of suspended monorails built in underground mining plants in non-methane and methane fields. Trolleys are adapted for installation in the transport set of an apparatus train driven by a self-locking shifting device. They can also be connected directly or in a transport set with a diesel locomotive, maneuvering cart, and other drive approved for use in the underground of mines.

Request for a quote

CARBOMECH SP. Z O.O.

Poland

Pallet has been designed for transportation of various electrical devices as well as other machinery and equipment by means of tracks of suspended monorails operating in underground mining facilities, in both non-methane and methane fields. The pallet is to be assembled in transportation sets of equipment transportation units driven by self-braking shifting devices. It may also be coupled directly or in a transportation set with a diesel locomotive, a handling trolley and another driving unit admitted to operation in underground mining facilities.

Request for a quote

PLASMA COMPANY LLC

Ukraine

Mining machinery and equipment is mainly used for mining operations. But, at present, it is widely used not only in the mining industry but also in such industries as metallurgy, mechanical engineering, energy, chemical industry, etc. If we talk about the classification of mining equipment, it is divided into mine, quarry, mineral processing, and transport equipment. A list of the equipment used in the mining and mineral processing industry is extremely large, it is boring machines, machines, and systems for underground mining; mining systems and automatics; mining machines and systems for open mining operations; jetting means mining operations; transport machines; machine mine water, ventilation and compressed air systems; machine mine hoist and others. We manufacture: Electric Pulling Winches Electric Scraper Winches Bottom Dump Muck Cars Rocker Dump Muck Cars Air Mucking Machines Electric Mucking Machines

Request for a quote

OGGO TECH MAKINA TEKNOLOJILERI SAN. TIC. LTD. ŞTI.

Turkey

Mining Industry, S355J2N Material, 8244 Kilograms

Request for a quote

TEKNIK MAKINA

Turkey

Dimensions: 40*400 cm 50*600 cm 60*600 cm

Request for a quote

TEKNIK MAKINA

Turkey

Flotation Tank Capacity a: 0.25 m3 0.37 m3 0.65 m3 1.20 m3 2.00 m3

Request for a quote

TEKNIK MAKINA

Turkey

Ball Mill Dimensions: Labratuar φ90×150 Cm φ120×150 Cm φ120×300 Cm φ150×150 Cm φ150×300 Cm φ200×150 Cm φ200×300 Cm

Request for a quoteResults for

Mining and quarrying - machinery and equipment - Import exportNumber of results

70 ProductsCountries

Company type

Category

- Mining and quarrying - machinery and equipment (68)

- Mining, surface - machinery and equipment (11)

- Concrete preparing - machinery and equipment (5)

- Construction - Machines & Equipment (2)

- Underground railways - equipment and rolling stock (2)

- Bag filling machinery and equipment (1)

- Extraction machinery and equipment - minerals and ores (1)

- Rubber - industrial machinery and equipment (1)

- Turning - steels and metals (1)