- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- mixers for the food industry

Results for

Mixers for the food industry - Import export

KASAG SWISS AG

Switzerland

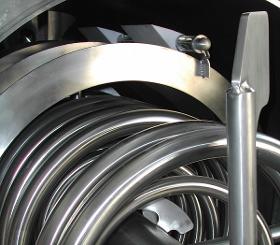

In order to prepare the fruit base, vegetables, jam, marmalade, jelly and sauces, horizontal or vertical mixing systems are used. Mixers are vital for attaining the highest product quality. The main aim is to ensure consistent mixing and temperature distribution by applying the lowest possible shear force on the pieces of the product. Since it is possible to thereby realise short process times along with the qualitatively high-value process apparatuses, KASAG has the ideal mixing technology for you. For the horizontal mixers, KASAG also has a special bearing and mechanical seal that has been tried and tested over many years. On an ongoing process to develop our mixing system and the bearing and mechanical seals further to attain optimal product quality and to enable smooth operation.

Request for a quote

GEPPERT RÜHRTECHNIK GMBH

Germany

NRK - Compact top-entry agitator The NRK series is a compact top-entry agitator that can be used to meet high requirements regarding both surfaces and cleaning inside and outside of the tank. Due to its’ compact design, agitator shafts with diameters of 25 mm and lengths of up to 1,200 mm can be realized, making the NRK the ideal mixer for small tanks in food and drug industry. GMP and FDA conform design. The NRK series agitator has an integrated bearing and coupling housing with flexible coupling to connect drives with shaft journals. The NRK can be supplied with radial shaft seal rings for non-pressurized operation or with liquid-lubricated mechanical seals on pressurized tanks. Explosion protection to ATEX 2014/34/EU for explosive zones 0 to 2 for gases and for explosive zones 20-22 for dusts (device group II, categories 1-3).

Request for a quote

GEPPERT RÜHRTECHNIK GMBH

Germany

The NRK series is a compact top-entry agitator that can be used to meet high requirements regarding both surfaces and cleaning inside and outside of the tank. Due to its’ compact design, agitator shafts with diameters of 25 mm and lengths of up to 1,200 mm can be realized, making the NRK the ideal mixer for small tanks in food and drug industry. GMP and FDA conform design. The NRK series agitator has an integrated bearing and coupling housing with flexible coupling to connect drives with shaft journals. The NRK can be supplied with radial shaft seal rings for non-pressurized operation or with liquid-lubricated mechanical seals on pressurized tanks. Explosion protection to ATEX 2014/34/EU for explosive zones 0 to 2 for gases and for explosive zones 20-22 for dusts (device group II, categories 1-3).

Request for a quote

BASE GROUP SP Z O.O.

Poland

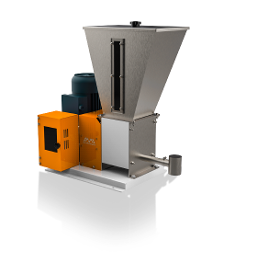

We have been manufacturing stainless steel machines and feeders constructions for food industry. The stainless steel structures are welded of different sizes and weight. Stainless steel feeders and mixers are among our currently manufactured products. We manufacture high quality steel constructions for food industry, which are customized to our customers’ individual needs and in accordance with the standards ISO-3834-2 and others international standards.

Request for a quote

GEBRÜDER LÖDIGE MASCHINENBAU GMBH

Germany

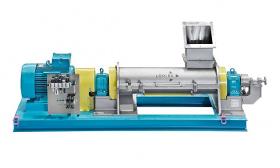

The CoriMix® is a high-speed, continuous mixer for high throughputs, especially developed for homogeneous mixing of liquid and pasty components into dry substances. The system is based on the high peripheral speed of the mixing shaft tools of up to 50 m/s. The product is moved through the mixing chamber in a plug-flow manner. The retention time is extremely short compared with a continuous ploughshare mixer. The mixing chamber is divided into zones with different mixing tools enabling different shear intensity by selecting and adjusting the mixing tools according to each application. Liquid components are introduced directly into the product ring layer – either via tangentially placed liquid pipes through the drum wall or via a hollow mixing shaft with specially perforated tools. However, moistening of the mixer wall and shaft is largely prevented. The liquid distribution is similar to a nozzle but avoiding any risk of clogging or disturbance of the spray.

Request for a quote

GEBRÜDER LÖDIGE MASCHINENBAU GMBH

Germany

The continuous ploughshare mixer uses the mixing and fluid process introduced to mixing technology by Lödige. The ploughshare shovels in special arrangement on a mixing shaft in a horizontal, cylindrical drum rotate. Their peripheral speed and geometric form are coordinated in such a way that the mix is moved out of the product bed against the centrifugal force and in axial direction at the same time. The mixing elements having a defined shape and a special arrangement on the shaft, they ensure not only a reliable product conveyance but also a sufficient back-mixing of the product. All the product is constantly involved in the process, ensures a maximum mixing intensity at even the highest throughputs and shortest residence times until the product is discharged out of the mixer via an outlet. The continuous process can be run at filling levels between 20 % and 50 % without influencing the mixing quality. Choppers can be additionally installed in the mixing drum.

Request for a quote

GEBRÜDER LÖDIGE MASCHINENBAU GMBH

Germany

The application range includes everything from processing of viscous components to paste-like products with poor flow. The range of food applications is exceptionally broad and there are also various applications for the pharmaceutical industry. The conical shape permits thorough residue-free discharge. The wet mixer system is a vertical mixing system for batch processes. The geometry of the conical or cylindrical mixing vessel, the arrangement and shape of the tools and their peripheral speed are adapted to each other in all sizes, resulting in effective mixing of all components. Depending on the process engineering tasks, the individual mixing tools are combined to form one tool both for material transport and for dispersion and disagglomeration processes. The installation height in the vessel is adjustable within a wide range. An adjustable deflector can be used to affect the product movement in a systematic fashion.

Request for a quote

GEBRÜDER LÖDIGE MASCHINENBAU GMBH

Germany

The laboratory model supplements the well-established Lödige mixing granulator range. The laboratory mixing granulator permits the same process steps as the production machines: — Mixing — Moistening — Granulation — Temperature control (using double jacket) The laboratory mixing granulator is delivered operation-ready with a CE conformity declaration. For the sizes, please refer to the machine flyer. A three-bladed impeller rotates at the bottom of the vertical, cylindrical mixing vessel, to create a vortex type of circulation for the material to be mixed. Very short mixing times and excellent mixing quality are achieved, even if the product components are extremely different. The separately driven chopper (only for the 5, 10 and 15 l vessel) is designed for breaking up of agglomerated material, for uniform moistening, wet granulation and streak-free mixing of dyes, as required.

Request for a quote

GEBRÜDER LÖDIGE MASCHINENBAU GMBH

Germany

The ploughshare mixer for batch operation uses the mixing and fluid process introduced to mixing technology by Lödige. The ploughshare shovels on the mixing shaft in a horizontal, cylindrical drum rotate to the wall. Their peripheral speed and geometric form are coordinated in such a way that the mix is moved out of the product bed against the centrifugal force and in axial direction at the same time. All the product is constantly involved in the process, ensures a maximum mixing intensity at even the highest throughputs and shortest residence times until the product is discharged out of the mixer via an outlet. Thanks to their form adapted to individual application and the speed adjustment, Lödige ploughshare mixers can be used for a wide range of applications. Choppers can be additionally installed in the mixing drum to increase the turbulence in the mixing process. This ensures the mixing of fine particles in small quantity and enables the dispersion of these products .

Request for a quote

WESTMARK GMBH

Germany

• with storage section • the self-adjusting spring-loaded mechanism holds the nutmeg against the blade with consistent force

Request for a quote

NORMIT

Slovakia

Drum coater provides easy operation and coating for snack. It’s used for seasoning, salting, adding sugar, adding various ingredients (cinnamon, vanilla, spice ...). Adjustable tilt frame assembly and design exposes each piece of product to the application of liquid and dry coatings. Depending on the application, the dosing of liquids may be through a dosing, perforated pipe and pump or hopper and conveyor system for dry materials. Depending on additional components, the system may be cyclical or continuous. Coating Drum Applications: •Different types of nuts •Chips •Pasta •Cereals •Meat Advantages •AISI 304 stainless steel cylinder. •Motor assembly with variable speed controller. •Variable tilt, stainless steel frame assembly. •Control panel. •Portable casters with brake assembly. •Equipped with paddles for even sprinkling •Drum rotation speed adjustment included •Adjusting the performance of the inclined installation •Possibility to change the height of the supporti

Request for a quote

NETZSCH MASTERMIX

United Kingdom

The NETZSCH Omega® Economic Dispersionizer is taking Dispersion One Step Further. Successful dispersion requires targeted force in order to separate agglomerated particles. The Omega® Economic Disperser applies dispersive forces then and there, where they are especially effective: in the Omega® disperser body, energy is transformed into very high speeds under pressure. Turbulence and cavitation in perfect combination with specifically-applied shearing forces ensure maximum dispersion results. In addition, the system can be easily adapted to different operating conditions or formulations thanks to the Omega® disperser body, which consists of a nozzle with infinitely adjustable flow properties. The optimum adaptation and increased efficiency not only lead to reduced energy consumption in the production process and thereby less heat development, but also to less wear as compared to traditional technologies. ** click to know more **

Request for a quote

NETZSCH MASTERMIX

United Kingdom

NETZSCH Alpha® is the next Generation of Agitator Bead Mills. Fresh creative standards were also set for the new Alpha® from the very beginning and a new expression of form was used that distinctly communicates the innovative strength of NETZSCH in the design as well. In place of the cast housing, external instruments and pipework there is a clear, dynamically-curved welded construction of heavy plating which also fulfills a load-bearing function. The ergonomic design of the machine stand was a primary consideration during the development phase. The Alpha® has a self-supporting grinding chamber, which ensures good accessibility to the grinding area during operation and maintenance. Thanks to the ergonomic mounting of the grinding chamber, changing products is quite easy, especially on the smaller models. The new Alpha® sets the standard when it comes to flexibility and handling and, thanks to its modularity, allows customer-specific solutions … ** click to know more **

Request for a quote

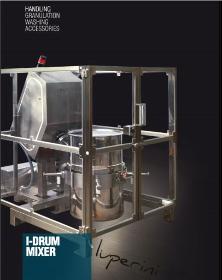

LUPERINI PRODUCTION SPA

Italy

Drum mixer machine is a compact and economical system for powder mixing in drums in all process where is required mixing and containment at the same time. The genlte rotation action provides higlhy effective blending results, very flexible from 50lt. to 300lt.

Request for a quote

MAKINSA BAKERY MACHINERY MFG & ENGINEERING

Turkey

Product is manufactured by international machinery industry standards and regulations.Innovative technology by high level engineering design has completed on this product. This is the laboratory type mixer and calling as table top mixer.For further information and pricing please feel free yourself to contact us

Request for a quote

HPM HIJYEN PROSES MAKINALARI

Turkey

Solution preparation systems and manufacturing vessels are the starting point of the production process. We produce Solution preparation mixer to provide efficient operation and desired Solution properties.

Request for a quote

MACHINES 4 FOOD LTD

United Kingdom

Dadaux Mixer Grinder Model TX114 ML Year 2012, in excellent condition Stainless steel construction ** In Stock - Ask for a quote **

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

REINASAN BV

Netherlands

Production processes often grind to a halt as pollution takes over. Daily cleaning is a necessary thing with relatively short effect. A momentary effect. To continue production processes, intensive and heavy alkaline chemical cleaners are used periodically to remove accumulated soiling. Reinasan has developed a system that ensures improved hygiene, less absenteeism, less waste, fewer process failures and it improves food safety, among other things. First, the 24/7 active protection agent is applied. Then one can clean or maintain daily with the pH neutral and environmentally friendly products. By measuring 'on the spot', you keep a grip on the cleaning and safety situation. We are also looking for distributors with their own B2B network. Let's become more sustainable together and leave the world cleaner behind than we found it!

Request for a quote

WEBER FOOD TECHNOLOGY GMBH

Germany

The Weber Slicer weSLICE 9500 is the new high-performance machine in the slicer portfolio, which once again set the standard with regards to quality and performance. On the one hand, the uncompromising slicing quality and performance is achieved using the new Weber DirectDrive technology. The product is precisely guided by the direct drive of all components, so that in addition to perfectly sliced, visually appealing slices, the highest portion weight accuracy is achieved while at the same time providing maximum protection for the product. On the other hand, equipment highlights such as the Weber Durablade Performance involute blade ensures the best slicing quality. Moreover, the Vario technology of the new slicer-flagship weSLICE 9500 contributes to this unique performance. If Weber vacuum gripper technology is used, the product yield is increased even further, as remaining end pieces are reduced by more than half.

Request for a quote

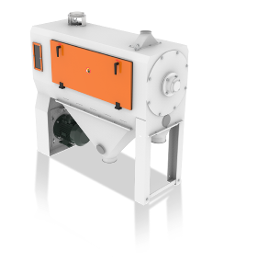

MAKENAS GRAIN MILLING TECHNOLOGY

Turkey

It is used to convey the granular and grinded products horizontally for collecting, distributing, mixing and tempering processes

Request for a quote

MAKENAS GRAIN MILLING TECHNOLOGY

Turkey

It is used to supply the vitamin as regularly at a suitable rate into ground flour by flour screw conveyor at flour mills

Request for a quote

MAKENAS GRAIN MILLING TECHNOLOGY

Turkey

It is designed to measure continuously material throughput rate and weight for monitoring of granular materials. The accurate information is obtained regarding mill yield by installing a group of scales on different product lines

Request for a quote

MAKENAS GRAIN MILLING TECHNOLOGY

Turkey

It is used to realize separating and grind process at the semolina passages in the flour diagrams, this process increases the yield of flour and consumes less energy comparing to other grinders

Request for a quote

MAKENAS GRAIN MILLING TECHNOLOGY

Turkey

It is designed to enrich and classify semolina in flour and semolina mills

Request for a quote

MAKENAS GRAIN MILLING TECHNOLOGY

Turkey

It is used in the grain processing plants, to ease the grain processing by neat and non-stop annealing and washing

Request for a quote

MAKENAS GRAIN MILLING TECHNOLOGY

Turkey

It is used to separate the flour particles, which are stuck and mixed with bran, contributing to the yield increase and preventing the waste of flour’s

Request for a quote

TRINMAK MACHINE ENGINEERING AND INFORMATION TECHNOLOGIES INDUSTRY

Turkey

The vertical vacuum packing machine is a specialized equipment used in packaging that removes air from a package or container, creating a vacuum environment. This equipment is commonly used across industries for preserving and extending the shelf life of perishable goods, protecting items from moisture and oxygen exposure, and maintaining product freshness.

Request for a quote

YONGMING MACHINERY MANUFACTURING CO., LTD

China

The 5XF-2000-80 Air-Screen Cleaner is a multi-purpose machine with pre-cleaning and sorting unit for mostly commercial crops. The operation of the machine is divided into two parts. In the first screening system with gravity separator, raw materials fall to the screen, then blight seeds are let to fall out using the eccentric shaft generated by the positive air pressure. Desired materials and larger impurities are moved forward to the top of the screen. Larger impurities are discharged from the outlet. Undersized contaminants and soil in materials fall by the next screen, while the desired materials continue to move ahead. Finally, all of the good materials are categorized into specific size dimensions i.e. big, medium and small sizes through grading screens. The cleaning system has elastic balls moving for preventing screen blockages. This product is the most sensitive screening and cleaning equipment with gravity separator and vibrating grader.

Request for a quote

PLANT OF TECHNOLOGICAL EQUIPMENT, LLC

Ukraine

We produce capacitive equipment of various purposes and designs, including stainless steels, and with weighting equipment, with a volume – from 1 to 50000 Equipment is provided with a frequency converter or fixed speed mixer, with a heating or cooling jacket, with the installation of electrical heating with temperature sensors and thermostat or according to your heating medium, cooler, vertically or horizontally standing, on the supports or on brackets for the overpass, with or without weighing equipment, with the number of hatches you need for maintenance and nozzles for supply and withdrawal of the product, with or without weight equipment. It is possible to complete with the cleaning heads and the flyover for maintenance.

Request for a quoteResults for

Mixers for the food industry - Import exportNumber of results

40 ProductsCountries

Company type

Category

- Mixers and grinders for the food processing industry (14)

- Food Industry - Machines & Equipment (9)

- Food industry packaging machinery (7)

- Lubricants, industrial (2)

- Washing systems for the food industry (2)

- Additives, food (1)

- Bakery - machinery and equipment (1)

- Bakery and confectionery industry - machinery and equipment (1)

- Chemical and pharmaceutical industry - machinery and equipment (1)

- Conveyor systems (1)

- Dairy products (1)

- Food industry - machinery and equipment (1)

- Mixers (1)

- Paint mixers and grinding machines (1)

- Pharmaceuticals – import-export (1)

- Wheels, castors and rollers (1)