JUKI AUTOMATION SYSTEMS GMBH

Germany

Manufacturer/ Producer

JUKI AUTOMATION SYSTEMS GMBH

Germany

Reflow Soldering Oven With its 10 heating zones and 2 cooling zones JUKI’s RS 1000 helps create even ambitious profiles and improve towards a high throughput of printed circuit boards respectively. Top flexibility is therefore guaranteed for future applications as well. In spite of a higher count of heating zones, the energy consumption is low.

Request for a quote

JUKI AUTOMATION SYSTEMS GMBH

Germany

Reflow Soldering Oven JUKI’s RS 800 8 zone reflow soldering oven embodies the best compromise between cost and effectiveness, floor space and energy consumption. With its 8 zones even complex soldering profiles can be constructed. 2 cooling zones ensure a suitable cooling down of the printed circuit boards after the soldering process.

Request for a quote

JUKI AUTOMATION SYSTEMS GMBH

Germany

Reflow Soldering Oven JUKI’s RS 600 6 zone reflow soldering oven is the space saving and inexpensive solution for the numerous standard SMT soldering tasks. Taking up a small amount of floor space and having low energy consumption, the machine has all the advantages of a larger reflow soldering oven such as perfect thermal properties as well as comprehensive equipment including useful features.

Request for a quote

JUKI AUTOMATION SYSTEMS GMBH

Germany

The provided software by JUKI encompasses individual modules for programme and production preparation, for the conversion of production data as well as for the optimisation of the complete production line – regardless of whether one is operating a single machine, a complete SMD production line or several lines. The software has a modular structure and is available in different licensing models to allow the greatest possible flexibility.

Request for a quote

JUKI AUTOMATION SYSTEMS GMBH

Germany

Handling Systems for Handling Printed Circuit Boards JUKI’s handling solution includes a wide range of reliable products to assure the secure handling of printed circuit boards involving SMT manufacturing conveyors; loaders and unloaders; buffers for PCBs; other systems such as turn units, stacker units; customised solutions for individual customer requirements etc. JUKI believes in durability and reliability. Our handling products are suitable for the requirements both of small and large production systems – while providing a highly attractive price performance ratio. Our partner Electro Design has more than 30 years of expertise in the development and manufacturing of handling systems for the electronic industry. In 1987, the company marketed its first conveyor belt and has since sold about 5,000 units to customers worldwide.

Request for a quote

JUKI AUTOMATION SYSTEMS GMBH

Germany

Visual Inspection of Surfaces This SE1000 Visual inspection measuring machine has been developed to automatically inspect the appearance of dirt, scratches, and other imperfections on various kinds of surfaces of your product. This 2D inspection technology can be used in production lines and is suitable for all kinds of industries that want to improve quality, reduce human involvement in inspection and reduce inspection time. Leveraging this fast, precise inspection machine will help you to improve the quality of your product dramatically.

Request for a quote

JUKI AUTOMATION SYSTEMS GMBH

Germany

Inspection of Surfaces 2D and 3D Regarding surface quality inspection for metal products such as cylinder head, gear tooth, it consumes a lot of time and human resources for the inspection. Since parts are inspected by bare eyes or slow speed inspection machines. With the inspection machine HE1000, inspection is much faster, more accurate and fully automated. In addition, there is a 3D laser sensor combined with our 2D inspection head to provide the most accurate result. This sensor is the first in the world to apply the Nobel Prize winning physics technology of optical frequency combs. It utilizes coaxial lasers and high precision range finders. There are some cases that our customers reduced over 90% of the inspection time. urthermore, if parts are inspected by humans, there might be different results by each person, because each of them has a different tendency and criterion.

Request for a quote

JUKI AUTOMATION SYSTEMS GMBH

Germany

This TM1000 Chain inspection machine has been developed to automatically inspect timing chains. It measures the coordinates of chain pins from the top and bottom surfaces. The machine also measures and quantifies the posture of pins relative to the position. A calibration certificate can be generated.

Request for a quoteManufacturer/ Producer

Neuburger Strasse 41

90451 Nürnberg - Germany

europages also recommends

A selection of companies related to the activity:

A selection of products that might interest you

LIVA GROUP ELECTRIC ELECTRONIC CONSTRUCTION

Turkey

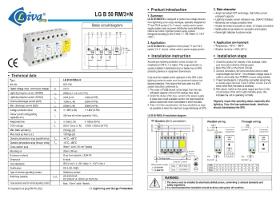

Adopt Hermetical GDT technology Lightning Impulse Current withstand max 250KA Extremely low voltage protection level Double terminals for parallel or series connection. Green lights indicates functional mode.

Request for a quote

XIAMEN NINESUN IMP. & EXP. CO., LTD

China

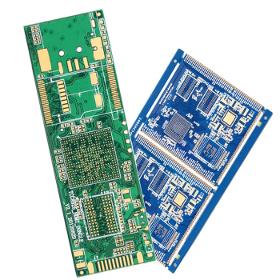

Place of Origin: China Base Material: FR-4 Copper Thickness: 1/2OZ 1OZ 2OZ 3OZ Board Thickness: 0.8mm Min. Hole Size: 0.1mm Min. Line Width: 0.065mm Min. Line Spacing: 0.065mm Surface Finishing: HASL Application: Electronics Device Type: Customizable Solder mask: Black Material: FR4 CEM1 CEM3 height TG Color: Red Blue Green Black Testing Service: 100% Supply Ability: 25000 Square Meter/Square Meters per Month

Request for a quote

LIVA GROUP ELECTRIC ELECTRONIC CONSTRUCTION

Turkey

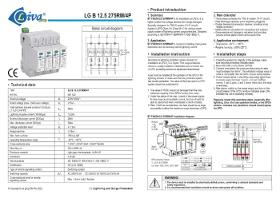

Three-phase protection for TNC-S System High discharge capacity ,quick response,pluggable Multifunctional conneciton for conductors and busbars Green window will change to red when fault and also provide remote alarm control at the same time

Request for a quote

NEWSUN PV TECHNOLOGY CO.,LTD

China

NSPV Solar fuse holder din rail 1000VDC NSDF38 type Features: Replaceable fuse; Flame retardant shell; A range of 10x38mm fuse links specifically designed for protecting photovoltaic strings; With mounting rails.

Request for a quoteRequest for quotes

Create one request and get multiple quotes form verified suppliers.

- Only relevant suppliers

- Data privacy compliant

- 100% free