- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- filling and sealing

Results for

Filling and sealing - Import export

FILLTECH GMBH

Germany

Costumer specific systems and Turnkey-Solutions Filltech designs, produces and implements fully automated gas filling solutions for the medical, consumer, industrial and special gas industry. All fully automated filling systems have been developed in close cooperation with the customer to ensure the best possible solution for their specific needs. Advantages Design of fully or semi-automated filling stations (in-house or in strong cooperation with your engineering team) One-stop-station for all necessary handling: emptying, cleaning, filling, weighing, leakage control, sealing and shielding In-house production of all filling stations Implementation at your premises Education at your premises 24/7 Back-up support available General capacity: 1000 CO 2 cylinders/hour IT-integration with your systems Track & Trace Ergonomic approach Conversions to AD2000 DIN/ISO 9001 ISO 22000 Module AI in accordance with RL 97/23/EG PED The following products might also be of interest to you: CO 2

Request for a quote

NHM LIMITED

Ukraine

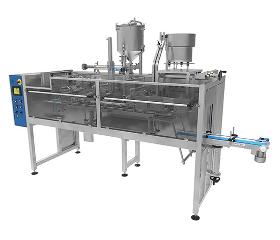

TECHNICAL DATAPARAMETER Speed, max.50 pouches/min. Filling volume, cm3100 – 1000 ml. (depending on filler) Type of packageready “”Doypack” pouch Packet width, max.200 mm Packet length, max.350 mm Electricals220 V, 50 Hz Power, kW1,5 Air consumption, l/min (0.6 Bar)460 Dimensions, mm2530x970x2190 Weight, kg850 WORKING PRINCIPLE Packaging machine grips empty “Doypack” pouch from a magazine, opens it, fills the product, prints date & seals the pouch. With the help of an orientator (optional) it can orientate and feed spouts to the sealing area and seal the spout vertically on to the pouch. Machine is equipped with parts for working with pouches of one width size. PRODUCTS TO BE PACKED: Food products: mayonnaise, condensed milk, jam, ketchup, tomato paste, sauces, tea, coffee, milk powder, rice, juices, cooking oil, etc. Non-food products: shampoo, liquid cleaning agents, fertilizers, cosmetic cream, window washer, toothpaste, washing powder, etc.

Request for a quote

NHM LIMITED

Ukraine

Automatic stacking system is an automatic system used for automatic counting and crating of polyethylene (LDPE) pouches in containers (polyethylene or carton cases). This system can be integrated into the working line with a Vertical Form-Fill-Seal (VFFS) packaging machine of any make. SPECIFICATIONVALUE PACKED PRODUCTPolyethylene pouches POUCH TYPEPillow pouch TYPE OF STACKINGIn bulk at 3 points PRODUCTIVITY*, MAXUp to 600 cases / hour RANGE OF POUCHES COUNTING IN A BOXFrom 1 to 99 pouches (depending on case and pouch dimensions) ELECTRICAL POWER (MAXIMUM)0.4 Kw, 380±4% V (3 phase), 50 Hz AIR CONSUMPTION~ 0.8 m3/hour WEIGHT~ 160 kg

Request for a quote

NHM LIMITED

Ukraine

TECHNICAL DATAPARAMETER Speed, max.*40 pouches/min. Packaging materialMultilayer film Pouch width, max.200 mm Pouch length, max.320 mm Roll diameter, max.500 mm Electricals220 V, 50 Hz Power, kW3,2 Air consumption, l/min (0.6 Bar)50 Dimensions, mm.3500x800x2000 Weight, kg., max.500 Automatic machine model ASP is designed to form empty “Doypack” pouches with open top from a roll of laminate film. These pouches are further used for filling various types of products and sealing manually or on packaging machine ADM. It is also possible to make “Doypack” pouches with ZIP-LOCK. ZIP-LOCK provides multiple opening and leak-proof closing of the pouch. “Doypack” pouch is a versatile type of package. It is possible to pack a wide range of liquid, viscous, solids, powders and small sized food, as well as non-food products in this packet.

Request for a quote

AHTPM

Turkey

Vertical Form Fill And Seal Machines BAG TYPES H/M series Continuous Model: Pillow Bags,Gusseted Bags H-Q/MQ Series : Quadro Bags, Pillow Bags, Gusseted Bags Series H6 SeriesContinuous Motion technology is highly used in a wide range of food and non-food packaging sectırs for its high-speed performance. Our H series are studied and designed carefully to avoid breaking fragile products while operating in a very high speed that can reach 200 rotation/ Minute M6 SeriesServo controlled intermittent motion system PLC and Servo System Technology are highly used in a wide range of food and non-food packaging sectors for their precise :Application: Food products : Powder, Granular, Sticky products, meat products, Frozen Food.....ect Non-food products: detergent, screws...ect GENERAL SPECIFICATIONS: 10” colored touch screen Stainless Steel Frame Servo controlled foil motion Servo controlled jaw motion P.I.

Request for a quote

AHTPM

Turkey

The G series packing machines work from reel to final bag. These machines are designed for forming, filling and sealing of doypack style pouches, 3 or 4 side sealed sachets, shaped pouches and pouches with spout. SPECIFICATIONS Full Servo Motion Control System 10’’ Hmi Lcd Touch Control Operating System Film Centering System Servo Controlled Scissors Servo Controlled Pouch Opening System With Vacuum Photocell Control System Heavy Duty Construction Servo Controlled Pouch Streching System No Open Bag No Fill System Zipper Aplication (Optional) Zipper Perforation And Opening System (Optional) Tear Notch System(Optional) Shaped Bag Molding System (Optional) Top Spout And Corner Spout Application System (Optional) Round Corner Application System (Optional) Euro Or Punch Hole Application System (Optional) Gas Flushing System (Optional) Inverter Controlled Roll Unwind System Printer Connection System (Optional) Stainless Steel M

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

Results for

Filling and sealing - Import exportNumber of results

6 ProductsCountries

Company type