- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- air cleaning

Results for

Air cleaning - Import export

SAMSYS GMBH

Germany

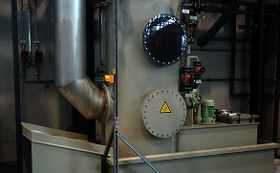

Oil mist separators are a must in order to ensure the extraction of oil mist from machine tools. With AOF filters we offer a whole series of extraction systems for effective extraction and filtration. The separator can filter emulsion mist, oil mist, smoke and odours. Oil mist filters can be installed on almost all turning machines– and milling machines and BAZ. In this way you can offer a healthy working environment for you and your employees. Heat and odours are effectively filtered and the emulsion separated from the exhaust air can be reused. The filters of the oil mist separators are equipped with multi-stage filtration. The elements are cleanable and reusable. Harmful emissions, dust and aerosols are removed from the air at almost 100%. Health hazards Oil mist and emulsion mist

Request for a quote

SAMSYS GMBH

Germany

Oil mist separators are a must in order to ensure the extraction of oil mist from machine tools. With AOF filters we offer a whole series of extraction systems for effective extraction and filtration. The separator can filter emulsion mist, oil mist, smoke and odours. Oil mist filters can be installed on almost all turning machines– and milling machines and BAZ. In this way you can offer a healthy working environment for you and your employees. Heat and odours are effectively filtered and the emulsion separated from the exhaust air can be reused. The filters of the oil mist separators are equipped with multi-stage filtration. The elements are cleanable and reusable. Harmful emissions, dust and aerosols are removed from the air at almost 100%. Health hazards Oil mist and emulsion mist

Request for a quote

SAMSYS GMBH

Germany

Oil mist separators are a must in order to ensure the extraction of oil mist from machine tools. With AOF filters we offer a whole series of extraction systems for effective extraction and filtration. The separator can filter emulsion mist, oil mist, smoke and odours. Oil mist filters can be installed on almost all turning machines– and milling machines and BAZ. In this way you can offer a healthy working environment for you and your employees. Heat and odours are effectively filtered and the emulsion separated from the exhaust air can be reused. The filters of the oil mist separators are equipped with multi-stage filtration. The elements are cleanable and reusable. Harmful emissions, dust and aerosols are removed from the air at almost 100%. Health hazards Oil mist and emulsion mist

Request for a quote

SAMSYS GMBH

Germany

Oil mist separator – extraction systems for vapours Oil mist separators are a must in order to ensure the extraction of oil mist from machine tools. With AOF filters we offer a whole series of extraction systems for effective extraction and filtration. The separator can filter emulsion mist, oil mist, smoke and odours. Oil mist filters can be installed on almost all turning machines– and milling machines and BAZ. In this way you can offer a healthy working environment for you and your employees. Heat and odours are effectively filtered and the emulsion separated from the exhaust air can be reused. The filters of the oil mist separators are equipped with multi-stage filtration. The elements are cleanable and reusable. Harmful emissions, dust and aerosols are removed from the air at almost 100%.

Request for a quote

MIKROPOR

Turkey

With more than 35 years of air filtration experience, Mia Air offers you the latest filtration technology. Mia Air has been designed to provide fresh clean air by trapping 99.999 % of ultra-fine particles in the air. It has 11 m2 filtration area and 100 m2 effective room coverage. By using HEPA filtration, which traps extremely small particles, Mia Air can transform polluted air into clean air in seconds.

Request for a quote

KLINEKS

Turkey

Klineks air conditioner and serpentine cleaner rips of all the oil, dirt, carbon and residues accumulated on cooling systems, air conditioners, honeycombs and apparatus on air conditioners, heating systems and aluminum metals. It creates a hygenic effect. Cleaning air conditioner is a recommendation for asthma and bronchitis patients. This product cleans and removes bacteria formed in filters and air conditioners over time.

Request for a quote

KLINEKS

Turkey

Klineks air conditioner and serpentine cleaner rips of all the oil, dirt, carbon and residues accumulated on cooling systems, air conditioners, honeycombs and apparatus on air conditioners, heating systems and aluminum metals. It creates a hygenic effect. Cleaning air conditioner is a recommendation for asthma and bronchitis patients. This product cleans and removes bacteria formed in filters and air conditioners over time.

Request for a quote

WESSEL-UMWELTTECHNIK GMBH

Germany

Exhaust air purification and heat recovery systems are generally not standard applications, even if individual assemblies are now modular. We have made it our goal to offer our customers the best solution for their task. To do this, we take a step back with our customers in order to gain an overview of the whole. Together we look at how the exhaust air is generated and try to start our concepts right at the point of origin. Only then can we decide which exhaust air system is the most economical when considering the total cost of ownership and compliance with the limit values. Should an extended consideration be necessary, we can accompany you from basic to authority to detail engineering. In addition, it is not uncommon for pilot tests to be offered, which lead to the later real scale of the systems by means of scaleup. With these consulting and engineering services, we offer you a manufacturerindependent package with which you can make the right decision for your company.

Request for a quote

WESSEL-UMWELTTECHNIK GMBH

Germany

In many incineration and industrial plants in various industries as well as in the municipal sector, dust emissions are produced during production processes. These emissions must be purified before they are released into the atmosphere. The dusts can be sticky, greasy, wet, dry or combustible and have different particle sizes. In general, they are between 0,1 and 1000 μm in size. Dust collection systems physically filter these dusts out of the exhaust air. WesselUmwelttechnik specialises in various methods of exhaust air cleaning, including industrial dust collector systems, to safely comply with legal requirements, e.g. the German TA Luft. In addition to dry filtering, the product range includes wet separators. This way, even humid and hot exhaust air as well as agglomerating dusts can be treated by the Wessel systems. The various exhaust air purification technologies allow the use of dust collecting systems in a wide variety of industries.

Request for a quote

WESSEL-UMWELTTECHNIK GMBH

Germany

Biological exhaust air cleaning is used whenever exhaust air has to be cleaned from volatile organic compounds (VOCs) and odours. Biofilters play a major role in this process. The polluted exhaust air is passed through a filter medium where the VOCs and odours are separated. Normally, this medium is an organic carrier material where microorganisms are grown on. They convert the VOCs and odours into noncritical components by means of their metabolism. Especially regarding the removal of odorous substances, biofilters are a very efficient and comparatively inexpensive way of biofiltration with an efficiency of up to 99 %. BIOCATbiofilters have a high degree of efficiency in a wide range of applications, even for exhaust air components that are difficult to dissolve in water.

Request for a quote

WESSEL-UMWELTTECHNIK GMBH

Germany

Biological exhaust air cleaning is always required if exhaust air needs to be purified of volatile organic components the socalled VOCs or odorous substances. The demand for biological procedures has increased in recent years. On the one hand, biological exhaust air cleaning does not generate any climaterelevant greenhouse gases. On the other hand, it meets all legal requirements for clean gas values. With over 200 biological exhaust air cleaning processes installed, Wessel has comprehensive practical knowhow and is the technology leader in the field of biological exhaust air cleaning. The biological exhaust air cleaning systems have been continuously optimised and further developed by WesselUmwelttechnik for decades. The modern cleaning systems from WesselUmwelttechnik work efficiently. Thanks to the continuous monitoring of the plant parameters, they require only a minimum of operating effort.

Request for a quote

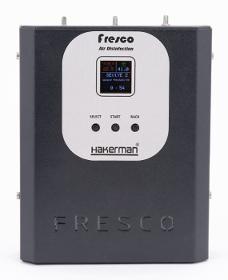

HAKERMAN CORP.

Turkey

Fresco hygienic air cleaning and disinfection device removes all kinds of bacteria, including corona, microbes, airborne pathogens, bad odors and other pollutants, in the air by periodically producing active oxygen and evaporating and spraying into the room in order to maintain indoor air quality during its operation. With ozone disinfection technology, it inactivates viruses by penetrating cellularly. TECHNICIAL SPECIFICATIONS Working Voltage: 12 Volt Ozonation Capacity: 200 mg/h Power Consumption: 8 Watts Display: 0.96 Inch Oled Body: Metal Operating Temperature: -33, +55 Degrees Celsius Feed Gas: Ambient Air Dimensions: 182.5 x 172.5 x 53 mm Weight: 2 Kg Extra Features Possibility to use in vehicle disinfection, Possibility of disinfection of fruits, vegetables, meat, fish in the kitchen Screw holes for wall hanger, 3M adhesive hook and loop tape for wall hanger, Ozone discharge holes made of stainless steel, long life corona discharge ozone generator, and so on..

Request for a quote

OZCON ENVIRONMENTAL

United Kingdom

1200i PRO is a Medical Grade Air Purifier with a Clean Air Delivery Rate of 1200 m3/h. 1200i PRO combines the most advanced 4-stage filtration technology currently available on the market. Medical-grade H13 HEPA NANO filters remove 99.97% of malicious particles from the air providing safe environments for both business and leisure. High efficiency in killing viruses (ie. Coronavirus) and bacteria, effective in removing unpleasant odours are ensured by the implementation of multiple filtering systems. 1200i PRO is an outstanding air purifier designed entirely for the comfort and health of you, your customers, your patients and your employees.

Request for a quote

RIEGLER & CO.KG

Germany

Compressed air preparation helps to prevent malfunctions on pneumatic components and increases their service life. Machine failures and downtimes are reduced. Whether compressed air preparation, regulation or cleaning, we have multi-part service units, from pressure regulators, filter controllers, oilers, condensate diverters and oil-water separators to system expansions and various accessories as well.

Request for a quote

RIEGLER & CO.KG

Germany

Compressed air preparation helps to prevent malfunctions on pneumatic components and increases their service life. Machine failures and downtimes are reduced. Whether compressed air preparation, regulation or cleaning, we have multi-part service units, from pressure regulators, filter controllers, oilers, condensate diverters and oil-water separators to system expansions and various accessories as well.

Request for a quote

RIEGLER & CO.KG

Germany

Compressed air preparation helps to prevent malfunctions on pneumatic components and increases their service life. Machine failures and downtimes are reduced. Whether compressed air preparation, regulation or cleaning, we have multi-part service units, from pressure regulators, filter controllers, oilers, condensate diverters and oil-water separators to system expansions and various accessories as well.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

RIEGLER & CO.KG

Germany

Compressed air preparation helps to prevent malfunctions on pneumatic components and increases their service life. Machine failures and downtimes are reduced. Whether compressed air preparation, regulation or cleaning, we have multi-part service units, from pressure regulators, filter controllers, oilers, condensate diverters and oil-water separators to system expansions and various accessories as well.

Request for a quote

RIEGLER & CO.KG

Germany

Compressed air preparation helps to prevent malfunctions on pneumatic components and increases their service life. Machine failures and downtimes are reduced. Whether compressed air preparation, regulation or cleaning, we have multi-part service units, from pressure regulators, filter controllers, oilers, condensate diverters and oil-water separators to system expansions and various accessories as well.

Request for a quote

RIEGLER & CO.KG

Germany

Compressed air preparation helps to prevent malfunctions on pneumatic components and increases their service life. Machine failures and downtimes are reduced. Whether compressed air preparation, regulation or cleaning, we have multi-part service units, from pressure regulators, filter controllers, oilers, condensate diverters and oil-water separators to system expansions and various accessories as well.

Request for a quote

RIEGLER & CO.KG

Germany

Compressed air preparation helps to prevent malfunctions on pneumatic components and increases their service life. Machine failures and downtimes are reduced. Whether compressed air preparation, regulation or cleaning, we have multi-part service units, from pressure regulators, filter controllers, oilers, condensate diverters and oil-water separators to system expansions and various accessories as well.

Request for a quote

RIEGLER & CO.KG

Germany

Compressed air preparation helps to prevent malfunctions on pneumatic components and increases their service life. Machine failures and downtimes are reduced. Whether compressed air preparation, regulation or cleaning, we have multi-part service units, from pressure regulators, filter controllers, oilers, condensate diverters and oil-water separators to system expansions and various accessories as well.

Request for a quote

SIA DV PELLET

Latvia

Hardwood Oak beams are designed primarily for construction purposes such as masonry wood construction. You can get the clean lumber beams, air dried as well as before or after planing, or rustic oak beam for construction and carpentry purposes in different sizes on demand.

Request for a quote

ROBINSON CO.

Turkey

The Air Channel is used for cleaning wheat, barley, legumes and soybeans. The machine removes all kinds of light materials different from cereal grains in terms of aerodynamic properties: garbage, straw and spike fractures, various seeds, peeled shell and dust from the product by means of air flow. While the grain products are distributed homogeneously in the width of the Air Channel with the feeding table of the machine or a vibrating feeder, the light particles in it are conveyed to the upper outlet channel with the air flow coming from the bottom, and the cleaned product falls down and transferred into the system. ◾ The lighting created by the window enables the separation to be seen clearly and thus all kinds of air adjustments can be made. ◾ Manufactured in two types, this machine with vibro motor is usually used with a Peeler machine, the non-motorized one is used with a Garbage Purifier machine.

Request for a quote

ROBINSON CO.

Turkey

It performs the task of separating the light grains and shells of the unwanted foreign substances from the grain with the air flow. The grain is spread over the bottom by a vibrating feeder and conveyed towards the air duct. It is washed by the air flow opposite the movement of the grain, which enters the air channel with a homogeneous distribution. In the meantime, unwanted light grains are separated from the grain by moving with the air. Applications Fields ◾ Food Industry ◾ Flour Mills ◾ Semolina Mills ◾ Feed Mills ◾ Grain Cleaning Plants ◾ Corn Processing Plants ◾ Oil Factories ◾ Plywood Factories ◾ Grain Storage Silos ◾ Corn Mills ◾ Corn, barley, rye, oats, and so on grain processing plants

Request for a quote

PARSMEGA MAKINA

Turkey

This type of filters are used to separate dust particles from dust-laden air, they can be used with positive or negative pressure, the filter bag is cleaned by 0.5 bar pressurized clean air that does not contain oil and water.

Request for a quote

PARSMEGA MAKINA

Turkey

It ensures the retention of dust and other light substances in the air coming from the cleaning machines. When the air containing dust coming from the dust aspirator is given tangentially to the cyclone, the dust in the air loses its speed as a result of cross-sectional expansion and falls by gravity, while clean air is discharged. Thus, the environmental impact of the air released outside the factory is minimized.

Request for a quote

PARSMEGA MAKINA

Turkey

The air purifies the flour dust mixture from flour dust, traps the flour dust and ensures that clean air is expelled from the chimney. Flour dust captured by specially woven bags returns to the system. Thus, flour loss is prevented. The filter section body is made of 2-6 mm sheet metal and the lower part is a cast iron plate. The transmission and engine parts are located on the cast plate. The gearmotor is mounted on the transmission as a battery. The transmission located in the filter section drives the steel plate arm also located in this section. There is an air suction cup on this steel arm. This air suction cup closes the filter bags on its upper part and located in the pipe section, one by one, at regular intervals (with the help of the transmission movement arm) and sucks the product inside. Meanwhile, the clean air included with the product

Request for a quote

ROBINSON CO.

Turkey

Jet filter cleans the air dust mixture from dust, keeps the dust and ensures that the clean air is discharged from the chimney. The circular filter body first performs the cyclone system purification, and ensures that all dust particles are retained through the bags. It is used to separate the particles in the air used for aspiration and transport in flour mills from the air. Air containing dust and flour enters the machine and this dust sticks to the filter bags in the machine. First purification is carried out thanks to the centrifugal power generated in the round filter body. These filter bags are whipped with compressed air and the dust goes down to the bottom of the filter. Blower or compressor is used for this cleaning process. A bottom scraper or rotoflow is used for throwing these dusts accumulated under the machine. Applications Fields ◾ Food industry ◾ Flour and semolina mills ◾ Feed mills ◾ Grain cleaning plants ◾ Corn processing plants

Request for a quoteResults for

Air cleaning - Import exportNumber of results

175 ProductsCountries

- Germany (61)

- Turkey (33)

- Netherlands (16)

- Italy (10)

- China (8)

- Belgium (6)

- Switzerland (6)

- United Kingdom (5)

- Austria (4)

- Ukraine (4)

- Poland (3)

- United States (3)

- France (2)

- Spain (2)

- Sweden (2)

- Thailand (2)

- Denmark (1)

- Greece (1)

- Latvia (1)

- Russia (1)

- Slovenia (1)

- South Korea (1)

- Taiwan R.O.C. (1)

- Viet Nam (1)

Company type

Category

- Air purification - equipment and systems (25)

- Filtering equipment and supplies (18)

- Air filtration equipment (11)

- Pneumatic systems and tools (9)

- Flour milling - machinery and equipment (6)

- Air conditioning, aeration and ventilation equipment (4)

- Oils, cooking - machinery and equipment (4)

- Sterilisation and disinfection - medical equipment (4)

- Agriculture - Machines & Equipment (3)

- Air treatment - equipment and systems (3)

- Electrical & Electronic Components (3)

- Ionisation equipment - air (3)

- Tableware (3)

- Ventilators and fans - domestic (3)

- Bird cages and aviaries (2)

- Bottling and filling - machinery and equipment (2)

- Car body repair shops - services (2)

- Food Industry - Machines & Equipment (2)

- Food Processing (2)

- Furniture for institutional kitchens (2)