- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- bottling lines

Results for

Bottling lines - Import export

TECHNIC MACHINES

Turkey

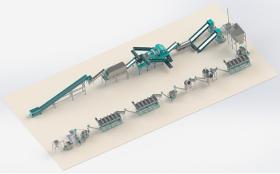

Our PET bottle recycle machine line is designed to give great recycling solution for PET bottle recycle process. We provide different solutions according to our customers PET bottle recycle machine demand, such as different capacity, dirtiness level, hot washing or cold washing system or etc. So we design our PET bottle recycle machine according to our customer's market requirements. Our PET bottle washing line can be designed for high level dirty PET bottles, with or without bales, Hot-Wash or Cold-Wash and etc. PET Bottles Recylce Machine Line Main Units, – Conveyor – Bale Opening Machine – Helezon – Cap and Label Remover – Sorting Belt – Drum Tromel – Conveyor Belt – Crusher Machine – Screw Loaders – Hot Washing Unit – Friction Washer – Flotation Tanks – Drying Units – Big Bag Filling Unit Just contact with us for your PET bottle recycling machine research, we will provide the optimum solution.

Request for a quote

SHANGHAI NPACK AUTOMATION EQUIPMENT CO., LTD.

China

Shanghai Npack offers the designing service, including the factory workshop construction, production packaging line layout, and turnkey projects.We not only designed the customized equipments, also providing the consulting service. After checking and confirmation the solution for the liquid, packagings, then we will offer you a details design.

Request for a quote

CMPLAST

Poland

We offer complete equipment for bottling, packaging lines, etc. among others snails, stars, guide tables, indexing wheels, complete systems for placing and positioning bottles, jars, cans, bottle closing heads, cap sorters, pouches, bottle closures, etc.

Request for a quote

SHANGHAI NPACK AUTOMATION EQUIPMENT CO., LTD.

China

when we receive an inquiry from customer, important to know the details about requirements, bottle or container samples and the factory layout, then we will offer a professional quotation, normally takes less 5 days.Npack made the liquid bottling equipment according to the confirmed solution which including the layout of the liquid bottling line,machine parameters, technical sheets, fetures,main components list,especially the layout of the line is very important. Confirmation the solution is a strict and important step to order packaging equipments, it can protect double benefits.Npack service some big brand companies, such as the GSK, KIMBERLY CLARK, we have much experience on these, it is a working attitude, also a working mothed to gurantee the customer profits.

Request for a quote

ENERCON INDUSTRIES LTD

United Kingdom

The benefits of induction technology in a capless sealing process. Successful sealing on both capless and non-screw-cap containers such as snap on caps is now possible with a pressure Sealer incorporating an Enercon Super Seal™ unit. Typically, pressure belt sealing is used to replace conduction sealing or to reduce the dwell-time needed in conduction sealing. Seals are either placed onto the capless containers or reside in the cap as inserted by the cap manufacturer. The capped container is then guided through the induction heating tunnel, where downward pressure is applied to the clip-on cap or foil by a non-metallic recirculating belt. This unique design automatically takes account of component variations and tolerances, such as bottle height variation, product overfill, line speed variation and bottle centres. Incorporates an Enercon Super Seal™ unit • Cap sizes up to 110mm diameter • Conveyor Speed up to 40 metres / minute

Request for a quote

SHANGHAI NPACK AUTOMATION EQUIPMENT CO., LTD.

China

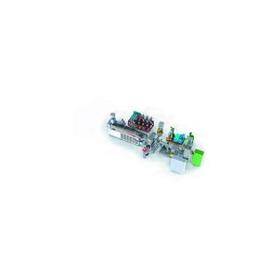

Press&snap capping machine is used for snapping press type caps, including three main parts: cap feeding system, cap loading system and cap snapping system. It is characterized by its simple structure and high qualification rate. Can be used alone or inline. Linear design makes it suitable for various caps & bottles with good adaptability, widely used for pressing jar cap, plastic bottle cap, can caps, in industries like food, beverages, cosmetics, chemicals,etc. The machine use the straight line into the bottle, automatically arrange caps, sleeving caps ,caps after sleeve and check will go into the gland system by the clamping belt. Due to the lid-cover flat belt design have a drop of slop, the caps after press will become more and more tightly.The machine has simple structure, convenient adjustment, production speed fast, high pass rate, after cap pressing has good performance, suitable for cap pressing of foodstuff, soy sauce, vinegar, vegetable oil’s bottle shape.

Request for a quote

BRINDES 360

Portugal

Natural line bottle, in a combination of stainless steel materials with a matt finish and bamboo. 750ml capacity, with safety cap and presented in an attractive eco design box. 750 ml

Request for a quote

BRINDES 360

Portugal

Natural line bottle of 500ml capacity. Made of glass body and bamboo screw cap, with practical braided handle in natural color. It includes a natural cork pouch and is presented in an attractive eco-design box. 500 ml. Individual Presentation. Natural Cork Bag Included

Request for a quote

KARATSIALIS BROS & CO

Greece

Can supply: PET BOTTLES with PVC label (approx. 100% CLEAR ) BALES SCRAP. Post consumer from sorting line. Bottles did not contain liquid inside due to the big pressing force of our baler machine. We have one of the strongest baler machine in Europe. Can load in 1x40HC container aprox. 26 - 28 MT net. Ready for shipment. Photos available upon request. If you are interested kindly contact us for more information (price, available quantity etc.). You are welcome to visit our company premises and supervise our materials. Best Regards, Karatsialis G. Athanasios, Sales Manager, Tel: +30 2310 681103 - Skype: Karatsialis.Athanasios . info(at)karatsialis.gr - www.karatsialis.gr Certificate ISO: 9001, ISO: 14001, OHSAS 45001, AQSIQ and CCIC.

Request for a quote

RAYUEN PACKAGING CO.,LIMITED

China

30ML thick bottom flint glass cosmetic dropper bottle made of various materials on each part, and each part of flint glass dropper bottles are indicated in the following table, it is the best skincare packaging source for decorated thick bottom flint glass dropper bottles with a pipette, the bottom of the dropper container is thick which is the unique feature among all the flint glass dropper bottles product line, the design of the dropper is special and beautiful, it is suitable for common skincare and personal care product as well as pharmaceutical products. Use for mainly used for skincare and personal care products, pharmaceutical products, lotion, essential oil, fragrance and essences and etc. Decoration available customized color, matte/glossy spraying, frosted, electroplating, printing and foil hot stamping.

Request for a quote

KARATSIALIS BROS & CO

Greece

Can supply: PET BOTTLES (aprox. 95% CLEAR - 5% COLORS) BALES SCRAP/WASTE. Post consumer from sorting line. Bottles did not contain liquid inside due to the big pressing force of our baler machine. We have one of the strongest baler machine in Europe. Can load in 1x40HC container aprox. 26 - 28 MT net. Ready for shipment. Photos available upon request. If you are interested kindly contact us for more information (price, available quantity etc.). You are welcome to visit our company premises and supervise our materials. Best Regards, Karatsialis G. Athanasios, Sales Manager, Tel: +30 2310 681103 - Skype: Karatsialis.Athanasios . info(at)karatsialis.gr - www.karatsialis.gr Certificate ISO: 9001, ISO: 14001, OHSAS 45001, AQSIQ and CCIC.

Request for a quote

CDA

France

The CDA Regionale stands out as a dedicated linear automatic labelling machine meticulously crafted for the wine industry. Its precision is assured by a timing system, ensuring swift and accurate labelling with a capacity of up to 1500 bottles per hour. Designed for the unique requirements of the wine sector, this automatic linear adhesive labelling machine is adept at applying up to four labels (main label, counter-label, neck label, and medal) to wine bottles. Additionally, it facilitates the crimping of both metal and PVC capsules. The Regionale is acclaimed for its user-friendly operation and its seamless adaptability to various wine bottle formats, including half-bottles, 75 cl bottles, magnums, and more. Its effortless integration into both existing and future bottling lines makes it an ideal choice for wineries.

Request for a quote

TASK ITALY SRL

Italy

The machine can handle pallets measuring 1000 x 1200, with a maximum height of 2000, with flat separators between layers of plastic or rigid cardboard containers or trays. It's a stationary platform depalletizer; with this system, it's possible to load the pallet into the machine already without the cardboard hood, using a pallet truck or forklift on the dedicated centering frame ensuring correct positioning. The machine features a robust and compact structure with linear guides to ensure movement precision. It utilizes inflatable rubber gripping heads for 3 rows of bottles, suitable for bottling lines with production rates up to 3,000 b/h. Alternatively, there's a version with gripping heads for picking up an entire layer of bottles. Magnetic gripping heads are also available for depalletizing metal cans. Format changeovers are simple and very fast by adjusting the position of the rubber according to the format. The machine is equipped with an electrical panel and control panel.

Request for a quote

CDA

France

The CDA R1000 Foils stands out as an automatic linear labelling machine meticulously crafted for Champagne bottles and sparkling wines. This automatic linear adhesive labelling machine excels at applying up to four labels (main label, back label, medal, and neck label) on Champagne bottles and sparkling wines, along with the added capability of crimping foils. Capable of labelling and crimping up to 800 bottles per hour, the R1000 Foils earns praise for its precision in labelling, user-friendly operation, and swift adaptability. This automatic linear labelling machine is ideally suited for bottles of various types (Champagne, CAVA, sparkling wine, etc.) and volumes (37.5 cl – 75 cl – Magnum – etc.). Effortless integration into both future and existing bottling lines further enhances the appeal of this versatile labelling machine.

Request for a quote

CDA

France

CDA's R1000/R1500 series encompasses automatic linear labelling machines specifically tailored for the wine industry. These machines are equipped to affix up to four labels—main label, back label, medal, and neck label—onto wine bottles, providing the added functionality of crimping metal or PVC capsules. With a commendable level of labelling precision across wine bottle sizes, the R1000/R1500 labelling machines boast a labeling capacity of up to 1500 bottles per hour. Setting themselves apart with user-friendly features, these machines in the R1000/R1500 series demonstrate seamless adaptability to diverse bottle formats (25 cl, 37.5 cl half bottle, 75 cl bottle, magnum, etc.) without the need for additional equipment. An automatic linear labeller from the CDA R1000/R1500 series can be effortlessly integrated into a comprehensive bottling line.

Request for a quote

TASK ITALY SRL

Italy

Washing machine for external cleaning of glass bottles and jars. The Lab-10 model is designed for integration into bottling lines with productions of up to 1200 bottles/hour (for higher productions, other models are available up to 10,000 bottles/hour). Thanks to its integrated traction motor and compact dimensions, its installation is simple and possible in any condition. The machine is equipped with a series of devices for the thorough washing of all parts of the bottle: - Adjustable-height upper brush for cap washing - Lower brush for bottom cleaning - High-speed rotating central vertical brush for washing the entire bottle surface Once the bottle washing is completed, two stainless steel blowing blades, powered by a high-pressure fan, ensure the drying of the entire surface for labeling.

Request for a quote

CDA

France

The CDA Lea machine stands as an automatic labelling solution meticulously crafted for the wine industry. This specialized machine adeptly applies up to four labels (front label, back label, neck label, and medal) to wine bottles and facilitates the crimping of metal and/or PVC capsules. With a pacing system in place, the Lea machine ensures swift and efficient bottle labelling, boasting a capacity of up to 2000 bottles per hour. Noteworthy for its user-friendly operation and seamless adaptability, this automatic labelling machine can swiftly adjust to various wine bottle sizes, ranging from half-bottles to Magnum, without requiring additional equipment. Ideal for integration into bottling lines, the CDA Lea machine is a versatile choice for the wine industry.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

TASK ITALY SRL

Italy

Automatic rinsers respectively with 4 and 6 positions operate using a water injection system with continuous flow. An optional recirculation kit with an integrated filtration system allows the use of a sterilizing or rinsing solution. An 'air blowing' version is also available. These machines allow the internal rinsing of new containers before filling, without wetting the exterior, using water previously filtered through a 0.35µm filtration cartridge. They do not require equipment for additional formats: format change is achieved through a few simple adjustments. The machines are entirely constructed in AISI 304 Stainless Steel and with plastic materials compliant with relevant directives. Machines provided in this manner are ready for integration into bottling or food packaging lines. Production: 800 bottles/hour for 4 positions - 1500 bottles/hour for 6 positions.

Request for a quote

FINN-KORKKI OY

Finland

Crown caps for your customised need. We manufacture crown cork bottle caps with different lining materials and colour options to meet your needs. Crown caps are suitable for glass, plastic, and aluminium bottles, and can be used for all kind of beverages. Crown caps are possible to get with standard Pantone PMS colours, plain one colour printing or multicolour CMYK printing. Also, it is possible to apply customer designed printing, including inside printing. For printing we use the offset printing method. Inside printing gives you more opportunities for product differentiation and marketing. Our crown caps are made of tinplated steel (TP, electrolytically coated or lined with tin) or tin free steel (TFS, chromium plated steel). We use BPA-free lacquers. A range of crown caps are available in standard stock colours. Plain stock colours of crown caps are available by the box.

Request for a quote

GENERAL VAPEUR S.R.L.

Italy

The Steam Master Wine is a machine for cleaning and sanitizing wine and oil cellars whose equipment can be cleaned optimally and effortlessly with the action of steam. It is an ecosustainable solution for cleaning and regenerating barrels, barriques and tonneaux, cleaning and sanitizing steel tanks, bottling lines, filters and housings, fittings and pipes. two versions of machines with 10 kW (6 lt boiler) and 19.5 kW (16 lt boiler) power pump with VITON components for mains hot water> 80 ° C two steam powers with L / selector H 1.3 bar pressure for barriques and wooden barrels 6 bar at 165 ° C for steel tanks and various applications soft wheels for nonplanar floors ease of handling inside the cellar

Request for a quote

EUROCORK

Belgium

Our wirehoods for sparkling wine, champagne, beer, cider and other sparkling beverages are produced from high-end raw materials to ensure the highest quality and flawless performance on bottling lines.

Request for a quote

PUNTO CURVATURA S.R.L.

Italy

Handling systems often require high-precision curves to follow a well-defined handling pattern. Punto Curvatura can bend all major monorail or two-rail transport lines in packaging equipment, sorting systems, airport baggage conveyor belts, production lines, bottling plants, food handling plants, treadmills and automated transportation.

Request for a quote

CL MACHINERY GMBH

Germany

Closure Systems International’s Series 900T capping machines are designed for reliability, low maintenance and flexibility. The machines’ high performance and flexibility allow bottlers to apply plastic closures for a wide variety of applications at the highest possible speeds. The capper’s stainless steel construction and easy-maintenance features help reduce bottlers’ total cost of operations. Best Reliability & Robustness Robust, durable construction for long-lasting performance Proven headset designs for consistent application and torque control Full stainless steel design Direct integration with any filler: various custom drive systems and pitch diameters to match filler, sorter, and other bottling line equipment choices Integrated PLC with touch screen to monitor application conditions and provide effortless user interface Auxiliary closure buffer for unexpected interruptions Quick, Easy Maintenance & Changeovers Simplified low maintenance requirements to reduce...

CL MACHINERY GMBH

Germany

Closure Systems International’s Series 200E capping machines are recognized as the "workhorse" of the capping industry for their reliability and low maintenance. The proven performance and flexibility allows bottlers to apply plastic and aluminum closures for a wide variety of applications at the highest possible speeds. Best Reliability & Robustness Robust, durable construction for long-lasting performance Proven headset designs for consistent application and torque control Corrosion-resistant materials in product zone; full stainless steel option Direct integration with any filler: various custom drive systems and pitch diameters to match filler, sorter and other bottling line equipment choices Integrated PLC with touch screen to monitor application conditions and provide effortless user interface Auxiliary closure buffer for unexpected interruptions Quick, Easy Maintenance & Changeovers Simplified low maintenance requirements to reduce downtime Totally enclosed washable...

CL MACHINERY GMBH

Germany

Closure Systems International’s Series 200 bottle cappers are the ultimate for aluminum roll-on applications. CSI's custom-engineered and precision built Series 200 cappers have been the preferred choice of the beverage and beer industry for decades. Industry’s Best TSROPP Performance Two cams provide independent control of top seal and thread forming, allowing precise control for specialty aluminum / roll-on packaging Perfect for roll-on closures requiring top/side sealing Robust, durable construction for long-lasting performance Corrosion-resistant materials in product zone; full stainless steel option Direct integration with any filler: various custom drive systems and pitch diameters to match filler, sorter and other bottling line equipment choices Open design for ease of cleaning Easy removal spindle assembles for quick maintenance Industry leader in Alumitec Application High-Speed, Consistent Application Industry-leading throughput at 50 BPM / 3,000 BPH per head Proven...

PROTEC POLYMER PROCESSING GMBH

Germany

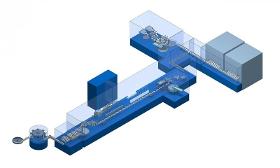

ProTec designs and supplies innovative solid-state polymer post-condensation lines and complete PET bottle flake recycling lines. The batch tumble reactor which combines homogeneous mixing with short processing times is the keystone of the line. The IV value (intrinsic viscosity as a yardstick for molar mass) of polyesters (PET, PBT, PTT etc.) and of polyamides (PA6, PA66 etc.) can be purposefully increased by precise control of temperature, vacuum and processing time, with or without defined addition of auxiliaries.

Request for a quote

GNEUSS KUNSTSTOFFTECHNIK GMBH

Germany

The MRS extruder processes undried PET bottle flake without any pre-treatment directly into pellets. The polymer melt is intensively and rapidly exchanged in the multiple screw section of the extruder. The huge surface area is exchanged at an unparalleled rate so that even with a moderate vacuum level of 25 to 40 mbar in the degassing section, contaminants are efficiently evaporated out of the melt. A letter of Non Objection (LNO) from the FDA underlines the decontamination efficiency. If, in order to boost the intrinsic viscosity (IV) a downstream solid state polymerisation system (SSP) is used, this can be specified far shorter than otherwise necessary as the extruder has already carried out the decontamination of the bottle flakes. The end product is of especially high quality with regard to transparency and yellowness.

Request for a quote

OPTIMA PHARMA GMBH

Germany

Aseptic fields of application Gently objective handling Dosing system: Rotary piston system, peristaltic pump system, time/pressure dosing system with or without CIP / SIP optional Statistical In-Process-Control (IPC) Optima with headquarters in Schwaebisch Hall, Germany, teams with its subsidiaries to design and build packaging equipment for pharmaceutical, consumer, nonwoven and life science products – from single standard machines to complete complex turnkey systems. Whether custom solutions or modular standard units, functions are consistently tailored to the specific needs of the customers and their industries. Optima is the worldwide leader in packaging technologies for many fields. Founded in 1922, the family owned and operated business is in its third generation and employs a workforce of 2,050 at its sites in Germany and 13 locations abroad. An export share of more than 80% is indicative of the company’s international standing.

OPTIMA PHARMA GMBH

Germany

100% In-Process-Control (100% IPC) ATEX model optional Gently objective handling Dosing system: Mass flow with CIP/ SIP optional Dosing system: Rotary piston system, peristaltic pump system Optima with headquarters in Schwaebisch Hall, Germany, teams with its subsidiaries to design and build packaging equipment for pharmaceutical, consumer, nonwoven and life science products – from single standard machines to complete complex turnkey systems. Whether custom solutions or modular standard units, functions are consistently tailored to the specific needs of the customers and their industries. Optima is the worldwide leader in packaging technologies for many fields. Founded in 1922, the family owned and operated business is in its third generation and employs a workforce of 2,050 at its sites in Germany and 13 locations abroad. An export share of more than 80% is indicative of the company’s international standing.

Results for

Bottling lines - Import exportNumber of results

34 ProductsCountries

Category

- Labelling machines (5)

- Bottling and filling - machinery and equipment (3)

- Bottles, metal (2)

- Pharmaceutical industry - machinery and equipment (2)

- Plastics - recovery and recycling (2)

- Scouring and pickling machines (2)

- Washing systems for the food industry (2)

- Bending - steels and metals (1)

- Beverage industry - machinery and equipment (1)

- Caps, metal (1)

- Cosmetics (1)

- Food Industry - Machines & Equipment (1)

- Food industry packaging machinery (1)

- Foundry machines - centrifugal (1)

- Lubrication equipment and machinery (1)

- Packaging (1)

- Palletising machinery (1)

- Plastic material processing (1)

- Plastics - machines and material for industry (1)

- Recycling - machines and installations (1)