- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- emergency stop buttons

Results for

Emergency stop buttons - Import export

SHANGHAI NPACK AUTOMATION EQUIPMENT CO., LTD.

China

Some key features of the IBC weighing filling machine may include: High-precision load cells Automatic tare and gross weighing functions Product-specific filling programs Easy-to-use touchscreen interfaces Automatic valve control for precise filling Automatic IBC positioning and clamping A range of safety features, such as emergency stop buttons and safety guarding Overall, the IBC weighing filling machine is an excellent investment for any business that requires accurate and efficient filling processes for intermediate bulk containers.

Request for a quote

SHANGHAI NPACK AUTOMATION EQUIPMENT CO., LTD.

China

Automatic drum liquid weighing filling machines are designed to fill drums with liquids using weight sensors and speed control technology. Some of the features of these machines include: Accuracy: These machines use weight sensors to ensure the accurate and consistent filling of drums with liquids. Speed control technology: The machines are equipped with speed-control technology, which allows for the precise and efficient filling of drums with liquids. Ease of use: The machines are designed to be user-friendly, with easy-to-use controls and quick changeover times. Versatility: These machines can handle a wide range of liquids from oils, solvents, chemicals, and other high-value liquids. Safety: The machines have built-in safety features, such as emergency stop buttons and guarding, to ensure operator safety. Low maintenance: Automatic drum filling machines are often designed for low maintenance

Request for a quote

SHANGHAI NPACK AUTOMATION EQUIPMENT CO., LTD.

China

Accurate weighing system: This machine is equipped with a highly accurate weighing system that ensures precise filling of liquids into drums. Easy to operate: The semi-automatic filling machine is user-friendly and easy to operate. It requires minimal training for operators to handle it. High filling speed: The machine has a high filling speed that helps save time and increase productivity. Durable construction: The robust construction of the machine ensures its longevity and stability. It is made of high-grade stainless steel, which makes it resistant to corrosion. Flexible design: This semi-automatic machine is highly adaptable to different sizes and shapes of drums. It can accommodate a wide range of container sizes and volumes. Low maintenance: The machine is designed for ease of maintenance and requires minimal upkeep. The components are easily accessible for routine cleaning and maintenance. Safe and reliable: With safety features such as emergency stop buttons and door sensors

Request for a quote

FERPLAST SNC

Italy

PNEUMATIC CENTERING DEVICE WITH MOTORIZED ROLLERS (MOD. CP-FM) MANUFACTURERS VERSION Feeder - centering device useful for centering boxes max width mm. 650 and max weight kg. 50. Can be combined with automatic taping and labeling machines. The box centering machine mod. CP-FM consists of a motorized roller conveyor and two pneumatically operated side guides. The metal parts are painted with epoxy powder while the other components are galvanized. The pneumatic centering device with motorized rollers is a module for builders to be completed and adapted to an automatic line. It is available in two versions: Manufacturers version and "plug and play" version: In the "manufacturers" version, the centering device is supplied complete with: - Motorized roller conveyor with start and stop button and emergency mushroom, at a fixed speed of 15 meters / minute - Pneumatic tail lifts and compressed air system up to the gate movement management valve.

Request for a quote

RM2M

France

The pendant push-button boxes of the RBAB range are the result of extensive ergonomics studies. They are extremely resistant to shocks that may occur in the industrial, logistics, or construction sectors. RM2M offers these push-button boxes with 2 to 12 control elements including: single speed button, double speed button, emergency stop (optional 2 NC contacts), 2 or 3 position fixed selector, key selector 2 or 3 fixed positions. Electrical contact life of 3 million cycles. Stock versions for control of hoists, hoist trolleys, and overhead cranes.

Request for a quote

TECSUP

France

All-terrain mobility: robust design, telescopic handle, pneumatic wheels, IP 65, IK 08 Control interface: on/off button, digital display with remaining operating time, emergency stop button Dimensions: H 625 x W 500 x L 297 mm Weight: 40 to 46 kg depending on model Equipment designed and manufactured in France, CE certified 2-year manufacturer's warranty

Request for a quote

GZ GUANGLI EFE CO., LTD.

China

GL1-N series automotive paint booth is a non-pitted paint booth offered in a standard configuration that includes exhaust fan and but excludes intake fan and heating system. It is typically used as sanding booth, primer booth and quick repair booth. Standard Configurations -Lighting system: upper lights are 8*4*18W LED light tubes, no lower lights; -A tool cabinet and an electric control panel are integrated in to the rear wall of this paint booth. The tool cabinet is designed to add extra storage capacity to keep supplies and tools which are commonly used for sanding and painting. And the electric control panel contains emergency stop button, single-phase & three-phase sockets, compressed air quick release couplings, etc. This greatly increases paintwork efficiency while avoiding unnecessary entering and exiting the paint booth; -Infrared paint curing lamp is optional;

Request for a quote

JING HENG SING TECHNOLOGY CO., LTD.

Taiwan R.O.C.

SUS304 material prevents steel rust from polluting food and working environment. (Option: SUS316 for food contact surfaces) SUS304 control box includes: mixing speed adjustment, timer, temperature, on/off button, hydraulic emergency stop, lift, lower, tilt and return to position. Food grade scraper blades, double jacketed bowl, leak proof design. Cooking vessel volume: from 100L to 500L. Power: 220V~415V (depends on request) Steam heating

Request for a quote

BERNSTEIN AG

Germany

The aluminium pressure die-cast protective shroud (F3: aluminium sand casting) fully shields the pedal at the top and sides while the wide base provides a high degree of stability. It reliably prevents accidental operation from above by falling objects or careless operation from the side. Due to its robust construction the protective shroud withstands a drop of 20 kg from a height of 1 m. The foot switch is uniquely designed to allow inclusion of additional equipment: — Emergency Stop button — Contactor on DIN rail as main power switch — Customized installations (e.g. light indicators)

Request for a quote

KEDY

Turkey

Introducing the KEDY K25000 Aluminium Anodizing Crane: the ultimate solution for handling and transporting aluminum parts during the anodizing process. The K25000 is designed specifically for the unique requirements of anodizing, with a lifting capacity of 4 tons, allowing you to easily handle and transport even the heaviest of aluminum parts. Powering the K25000 is an energy-efficient electric motor, providing the crane with the power it needs to get the job done. The crane's control system is computerized, ensuring that you have full control over the crane's movement and speed at all times. The crane also comes with a remote control option, allowing you to operate the crane from a safe distance. Safety is a top priority at KEDY, and the K25000 is no exception. The crane is equipped with emergency stop buttons, load limiters, and anti-collision systems to ensure that accidents and injuries are prevented. Invest in the KEDY K25000 Aluminium Anodizing Crane now!

Request for a quote

KEDY

Turkey

Introducing the K3100 Electric Roll Lifting and Handling Equipment from KEDY – the ultimate solution for safe and efficient handling of rolls of material in your facility. With a maximum load capacity of 1100 kg, the K3100 is able to handle even the heaviest of rolls with ease. Its state-of-the-art clamping system, featuring jaws and arms, can easily adjust to accommodate rolls of different sizes and weights, ensuring a secure grip and safe movement every time. It also features a user-friendly control system that allows for easy operation and automation, increasing productivity and reducing the risk of operator error. Safety is of the utmost importance to KEDY, and the K3100 is no exception. It is equipped with a range of safety features including emergency stop buttons, load limiters, and sensors, ensuring the safety of the operator and those around the equipment at all times. Upgrade your material handling operations with the K3100 Electric Roll Lifting and Handling Equipment!

Request for a quote

KEDY

Turkey

Introduce the K5200 Sheet Metal Tong & Sheet Lifter from KEDY. The ultimate solution for safe and efficient handling of large sheets of metal. With a maximum load capacity of 20 tons, it can easily handle even the heaviest sheets of metal. Equipped with remote control, it allows the operator to easily extend and retract the arms of the tong from a distance, making it a convenient and efficient tool for handling large sheets of metal. The sheet metal tong is also designed with safety in mind, it has an emergency stop button, programmable memory, auto-grip and overload protection, ensuring that the operator is always in control. It's compact, lightweight and easy to transport, making it ideal for worksites of all sizes. Upgrade your metal handling operation today with the K5200 sheet metal tong and sheet lifter from KEDY. Contact us today to place your order and experience the benefits of the K5200 sheet metal tong and sheet lifter for yourself!

Request for a quote

GUNDEM SAGLIK VE GIDA URUNLERI SAN. VE TIC. A. S.

Turkey

It meets the requirements of the World Health Organization (WHO) guideline as well as the current guideline of the World Federation of Hospital Sterilization Sciences (WFHSS). CE Certified, provides verifiable sealing according to EN ISO 116072 and international guide ISO/TS 16775 • Body All Stainless White oven painted • Display Adjustable constant temperature system with digital display • Control With Microprocessor • High speed Capacity to process pouches at 11 m/min • Sealing type and width MultiLine sealing, 14mm. • Special coating on heaters New technology system without Teflon® fabric on heaters, which is old technology and requires frequent replacement, Technical Service and Spare Parts • StandBy If no pouch is supplied to the device, 15 seconds. after mechanism stop, mechanical protection • Device safety Emergency Back, Emergency Stop and Emergency Back buttons. If the pouch gets stuck in the device, it prevents it from melting inside and disrupting the work.

Request for a quote

GUNDEM SAGLIK VE GIDA URUNLERI SAN. VE TIC. A. S.

Turkey

It meets the requirements of the (WHO) guideline as well as the current guideline of the (WFHSS). CE Certified, provides verifiable sealing according to EN ISO 116072 and international guide ISO/TS 16775 • Body All Stainless White oven painted • Display Adjustable constant temperature system with digital display • High speed Capacity to process pouches at 11 m/min • Sealing type and width MultiLine sealing, 14mm. • Special coating on heaters New technology system without Teflon® fabric on heaters, which is old technology and requires frequent replacement, Technical Service and Spare Parts • Device safety Emergency Back, Emergency Stop and Emergency Back buttons. If the pouch gets stuck in the device, it prevents it from melting inside and disrupting the work. • Easy serviceability easy access to parts thanks to modular device structure • Maintenance periyod 1 time per year • Warranty 2 Years • Lifespan >15 years.

Request for a quote

PROXOMED® MEDIZINTECHNIK GMBH

Germany

Technical data Dimensions (L/W/H) 210/82.5/140 cm Total weight approximately 178 kg Rise 0% – 20% Equipment High-definition touchscreen Integrated chip card system in series Emergency stop function button Safety line with magnetic emergency stop Training programmes Quick start, pulse-controlled programmes, performance-controlled programmes, performance-sensitive programmes, various profiles Options Med. RS-232 Isolator including cable Medical LAN isolator Pulse receiver, polar-coded Polar Sender Set T 31, uncoded Polar Sender Set, T 31, coded 3-year warranty extension proxotrain software, IPN-Test Suite

Request for a quote

MAKSAN INDUSTRIAL KITCHEN EQUIPMENTS

Turkey

GENARAL FEATURES · 18/10 304 AISI Stainless steel chasis construction · Modern and stylish design · Magnetic door switch · High quality stainless steel heaters · Cycle start at door closing · Digital temperature display · Individual pre-wash and wash tank · Pre-heated boiler tank system · Conveyor system with dual-stage speed · Safety switches · User-friendly control interface · Height-adjustable legs · Possibility of attaching the drain and rinse pump (optional) Emergency stop button for safety

Request for a quote

FMH CONVEYORS INTERNATIONAL LIMITED

Germany

The Mobile Loader is designed specifically for use in premises without a raised loading dock, which makes it ideal for loading vans and other smaller vehicles. Using this unit makes your vehicle loading/unloading operation faster, safer and more efficient, and helps you comply with manual handling regulations. Construction Heavyduty construction and supporting framework make Mobile Loaders one of the most robust units of its type on the market. Shrouded Buttons To limit the damage to emergency stops, FMH Conveyors add fabricated steel shrouds to the exposed emergency stop buttons. Fully Guarded All moving or rotating parts are fully guarded to prevent entrapment and injury. Mobile Mobile Loader units are fully mobile utilising 200mm heavy duty castors.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

ROTAKEM

Turkey

Technical specifications : 1. Origin: Russia 2. Renovation year: 2020 3. roll diameter: 660 mm 4. Roller length: 1500 mm 5. Front roll liner speed: 15 rpm 6. speed ratio of rolls: 1: 1,15 7. Roller opening range: 1-30 mm 8. Motor power: 160 kW 9. Engine-transmission transmission type: belt / pulley system 10. Transmission type between gearbox shaft: Direct coupling 11. Bearings: Ball Bearing 12. Lubrication: Automatic 13. Cooling system: Central cooled with water head 14. Visor: Fixed 15. Safety: - 4 emergency stop buttons - 2 emergency stop bars - 2 emergency stop pedals - Return - Engine brake 16. New chassis 17. Shafts ground 18. New electrical and control panel 19. Optional: - Stock blender - Automatic on / off - Motor drive

Request for a quote

ROTAKEM

Turkey

Technicial Specifications 1. Year of construction: 2006 2. Revision Year: 2020 3.Cylinder diameter: 660 mm 4. Roller length: 2135 mm 5. Front roller speed: 13 rev / min 6.Friction ratio: 1 - 1.22 7.Cylinder opening range: 1-15 mm 8.Motor power: 280 kW 9. Reducer: Jahnel 450 kW 10. Engine-gearbox transmission type: Direct coupled 11. Transmission type between gearbox and mills: Direct coupled 12. Bearings: Bronze 13. Lubrication: Automatic 14. Cooling system: Central cooled with rotary joint 15. Visor: Fixed 16. Security: - 4 emergency stop buttons - 2 emergency stop bars - 2 emergency stop pedals - Return - Engine brake 17. New chassis 18. Mills grinded 19. New electrical and control panel 20. Optional: - Stock blender - Auto turn on / off - motor driver *** All pictures are before revision

Request for a quote

ROTAKEM

Turkey

Technicial Specifications : 1. Manufacturer: Farrel 2. Renovation year: 2020 3.Cylinder diameter: 660 mm 4. Roller length: 2135 mm 5. Front roller speed: 12 rpm 6.Friction ratio: 1: 1,2 7.Cylinder opening range: 1-15 mm 8.Motor: 250 kW DC 9. Engine-gearbox transmission type: Direct coupled 10. Transmission type between gearbox and mills: Direct coupled 11. Bearings: Bronze 12. Lubrication: Automatic 13. Cooling system: Central cooling with rotary joint 14. Visor: Fixed 15. Security: - 4 emergency stop buttons - 2 emergency stop bars - 2 emergency stop pedals - Return Engine brake 16. New chassis 17. Mills are grinded 18. New electrical and control panel 19. Optional: - Stock blender - Auto turn on / off - Motorcycle driver *** All pictures are before revision

Request for a quote

ROTAKEM

Turkey

Technicial Specifications: 1. Revision year: 2020 2.Cylinder diameter: 660 mm 3.Cylinder length: 2130 mm 4. Roller opening range: 1-15 mm 5. Motor power: 200 kW 6. Engine-gearbox transmission type: Direct coupled 7.Transmission between gearbox and mills: Flywheel gear 8. Bearings: Bronze 9. Lubrication: Automatic 10. Cooling system: Closed circuit water cooling system with rotary joint 11. Visor: Fixed 12. Brake system: - 4 emergency stop buttons - 2 emergency stop bars - 2 emergency stop pedals - Return - Engine brake - Automatic on / off 13. New chassis 14. Mills grinded 15. New electrical and control panel 16. Optional: - Stock blender - Motor driver *** All pictures are before revision

Request for a quotePOUGET

France

The POUGET VT.3 Vibrating Tamping Set is supplied with : 1 Generating Set (petrol or diesel) three phase 220/380 V-50 Hz with an automatic safety brake, mounted on 2 rubber wheels. Fuel Motor Power (KVA) Weight (Kg) Essence HONDA LOMBARDINI 6 7 100 106 Diesel HATZ LOMBARDINI 6 112 4 Portable Vibrating Tampers at individual drive with automatic safety brake switch, and 10 meters insulated protective cable. . - Multiple vibrating directions - Unit power = 0,77 KW - Vibrations/min. : 50 Hz - Vibrating strength of tamping-blade : 660 Kg - Hardeness of tips = 63/68 Rockwell C - Unit weight of each tamper : 32 Kg The Portable Vibrating Tamping Machine is equipped with an operating adjustable handle in height and one safety brake switch. 1 Distributor Panel with : - 1 cable reel comprising 50 m. - 1 emergency stop button - 4 security connection - 1 general brake - weight = 32 Kg Noise level for the Workmen in operation : 90 dB (A) Vibrating level on Workmen handles : 5 m/s² IMPORTANT :

Request for a quote

JAY ELECTRONIQUE

France

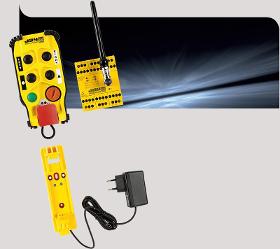

Wireless emergency stop 4 function buttons + start/stop Light-weight, compact and ergonomic transmitters IP65 tightness, protective foams Integrated rechargeable battery Transmitter support charger Wireless emergency stop with safety PL e EN13849 and SIL 3 EN61508 6 static outputs + 2 safety relays 64 frequencies in 433MHz Infrared start-up option

JME LTD

United Kingdom

JME design and manufacture digital radiography systems to meet customers specific inspection requirements. All JME (DR) Systems are built with an integrated safety system, which includes emergency stop buttons and monitored door interlocks, audible pre-warning and fail safe warning lamps. All JME (DR) systems meet all the statutory requirements of the current Ionising Radiation Regulations (IRR99). Wet film radiography has been accepted and used as a NDT technique for many years. However new X-Ray imaging techniques are now available and offer many advantages over film. As a leader in the field of advanced inspection equipment JME can offer Digital radiography (DR) to our customers. JME can provide advice on choosing and using our DR systems, radiographic techniques and safety requirements. Conduct feasibility studies and trials. Design and manufacture turn key solutions. Supply X-Ray sources. Supply assessor and image manipulation software. Provide after sales service and repair.

Request for a quote

TAŞMAK METAL MACHINERY LTD.

Turkey

-RPM selection for different materials with the 2-speed motor -45° right hand to 45° left hand saw positioning, accurate and precise cutting in two directions -Coolant circulation to remove materials' chips and to cool the disc -Adjustable gear according to the size of the material -Comes with a stop rod for repeatable cuts -24 V low voltage system -Emergency stop button -Safety regulations,according to CE Standards -Moving saw protection guard -Motor protection kit -Burr-free cutting -Hassle-free performance

Request for a quote

TAŞMAK METAL MACHINERY LTD.

Turkey

-RPM selection for different materials with the 2-speed motor -45° right hand to 45° left hand saw positioning, accurate and precise cutting in two directions -Coolant circulation to remove materials' chips and to cool the disc -Adjustable gear according to the size of the material -Comes with a stop rod for repeatable cuts -24 V low voltage system -Emergency stop button -Safety regulations, according to CE Standards -Moving saw protection guard -Motor protection kit -Burr-free cutting -Hassle-free performance

Request for a quote

TAŞMAK METAL MACHINERY LTD.

Turkey

-RPM selection for different materials with the 2-speed motor -45° right hand to 45° left hand saw positioning, accurate and precise cutting in two directions -Coolant circulation to remove materials' chips and to cool the disc -Adjustable gear according to the size of the material -24 V low voltage system -Emergency stop button -Moving saw protection guard -Motor protection kit -Burr-free cutting -Precise cutting by centering the material with the double-sided pneumatic vice control -Comes with a stop rod for repeatable cuts

Request for a quote

TAŞMAK METAL MACHINERY LTD.

Turkey

-RPM selection for different materials with the 2-speed motor -45° right hand to 45° left hand saw positioning, accurate cutting in two directions -Coolant circulation to remove materials' chips and to cool the disc -Adjustable gear according to the size of the material -24 V low voltage systems -Emergency stop button -Safety regulations, according to CE Standards -Moving saw protection guard -Motor protection kit -Burr-free cutting -Automatic cutting by centering the material with the double-sided pneumatic vice control -Comes with a stop rod for repeatable cuts -Process counter -Hassle-free performance

Request for a quote

TAŞMAK METAL MACHINERY LTD.

Turkey

-RPM selection for different materials with the 2-speed motor -45° right hand to 45° left hand saw positioning, accurate and precise cutting in two directions -Coolant circulation to remove materials' chips and to cool the disc -Adjustable gear according to the size of the material -24 V low voltage system -Emergency stop button -Moving saw protection guard -Motor protection kit -Burr-free cutting -Precise cutting by centering the material with the double-sided pneumatic vice -control -Comes with a stop rod for repeatable cuts -Hassle-free performance

Request for a quoteResults for

Emergency stop buttons - Import exportNumber of results

36 ProductsCountries

Company type

Category

- Cutting - steels and metals (6)

- Forming, rubber - machinery (4)

- Bottling and filling - machinery and equipment (3)

- Conveyor systems (2)

- Package sealing machinery (2)

- Switches (2)

- Batteries (1)

- Beauty salons - equipment (1)

- Bending machine tools (1)

- Cranes and gantries (1)

- Dishwashing machines for institutions (1)

- Electricity generators (1)

- Foods, precooked and gourmet (1)

- Laser - cutting and welding machines (1)

- Lifting equipment (1)

- Lifting equipment - accessories (1)

- Painting machinery and equipment (1)

- Pneumatic conveyor equipment (1)

- Production and operational inspection (1)

- Stackers (1)