- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- measurement - equipment & instruments

Results for

Measurement - equipment & instruments - Import export

FLUKE PROCESS INSTRUMENTS GMBH

Germany

The Raytek MI3 infrared temperature thermometer is a two-piece system with a miniature sensing head and separate communications electronics. The OEM version allows direct digital communication with the host machine controller without the need for an additional communication box. The innovative multiple sensing head interface, which can support up to 8 individually addressable heads per communication box, reduces sensor cost, simplifies sensor installation and applications troubleshooting, and provides the lowest cost per measurement point. Raytek MI3 ATEX/IECEx certified sensors can be used safely to monitor the right temperature of hazardous areas / processes with explosive atmospheres. All standard MI3 and MI3100 heads can be ordered with optional ATEX/IECEx certification. One specifically provided Ex-proof power supply can be used with 2 sensing heads.

Request for a quote

FLUKE PROCESS INSTRUMENTS GMBH

Germany

Raytek GS150 thermal imaging systems enable automated quality control in glass bending, forming, annealing, and tempering processes. The GS150LE variant is especially designed for Low-E (low emissivity) glass / one-side coated flat glass. It features automatic emissivity correction. The systems are based on the Raytek MP150 infrared line scanner, which has a max. resolution of 1024 points per line, a max. 150 Hz scanning frequency, and an up to 90° wide field of view. SYSTEM PROPERTIES • Automated temperature monitoring • Visualization on PC • Ethernet TCP/IP interface integrated in the line scanning system • PC-independent alarm output • PC-independent analog outputs 3 x 4 – 20mA BENEFITS • Improve profitability and product quality • Reduce set-up time • Detect defects quickly • Automate quality monitoring for ISO9000 • Reduce scrap • Efficiently manage the heat balance in the oven • Automatically adjust the emissivity value when changing glass types or coatings

Request for a quote

FLUKE PROCESS INSTRUMENTS GMBH

Germany

Thermalert 4.0 infrared temperature sensors provide accurate temperature measurement from -40 °C to 2250 °C (-40 °F to 4082 °F) for a wide variety of process control applications. • Durable stainless steel IP65 / NEMA4 enclosures designed to withstand ambient temperatures from -20 °C to 85 °C (-4 °F to 185 °F) • Integrated laser sighting • Galvanically insulated outputs • Plastic lens option for food applications • Analog input for ambient compensation and adjusting emissivity setting • Multiple interfaces – 2-wire loop powered for analog and digital communication – 12 wires M16 and 6-pins terminal block for digital communication (RS485) • USB for easy setup • Simple, two-wire or digital installation • Advanced signal processing • Wide choice of focus distances • 2-year guarantee The program includes various models and accessories. The DataTemp® Multidrop software enables easy configuration and process monitoring on a real-time graphical display.

Request for a quote

FLUKE PROCESS INSTRUMENTS GMBH

Germany

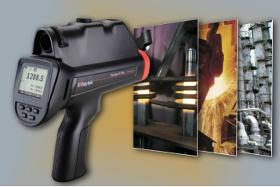

The Raytek Raynger 3i Plus handheld infrared thermometer is designed to meet process performance requirements in industrial applications, including highly demanding hot environments in primary and secondary metal processing, as well as petrochemical and power plant operations. The rugged pyrometer withstands a 1m (3.2ft) drop test and provides a longer operational cycle for up to 24 hours when powered with rechargeable batteries. Its intuitive user interface enables easy parameterization and ‘on-site’ display of data analysis and trending, as well as fast and easy data transfer to a PC or smartphone using USB or Bluetooth. It features a high 250:1 optical resolution, which ensures accurate temperature readings at longer distances. Heat resistant “Red Nose” warning detector ensures operator safety and efficiency. Dual laser and scope sighting, visible even against "red hot" backgrounds, make this IR thermometer a perfect choice for hot temperatures applications.

Request for a quote

FLUKE PROCESS INSTRUMENTS GMBH

Germany

ThermoView TV40 is a high-performance industrial thermal imaging system for fixed installation designed for factory automation applications. It integrates a visible-light camera and software for temperature control, monitoring, and data archiving. • Wide temperature range: -10 to 1200 °C (14 to 2192 °F) • Rugged aluminum housing, IP67 (NEMA 4) • Ambient temperatures to 200 °C (392 °F) with high-temperature enclosure • Air purge and accessories available • IR-Fusion technology: simultaneous thermal and visible sighting • Remote motorized focus • 320 x 240 and 640 x 480 focal plane array • 9 or 60 Hz models available • GigE Vision interface • LAN/Ethernet with PoE for communication with the camera provides access to Ethernet, Web server and ThermoView Software • Multiple field interchangeable lens options • 2-year warranty

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

FLUKE PROCESS INSTRUMENTS GMBH

Germany

The IRCON ScanIR3 infrared linescanner provides real-time, thermal imaging of continuous sheet and web-based processes as well as discrete manufacturing processes. The robust housing includes built-in provisions for water-cooling and air-purge, and features built-in laser sighting. A rugged processor box provides universal input and output capabilities in the field without the need for an external computer. The versatile ScanView Pro software allows for custom configuration of operating parameters and display of thermal images and temperature profiles on a standard PC. Features: Fast scan speed up to 150 lines per second Up to 1024 measurement points per line High optical resolution up to 200:1 (allows for installation further from the measured process with excellent precision) Reliable Ethernet communication (optional fiber optics) Brushless scanning motor Field-replaceable window One bundled sensing head cable with one-click connector to the scanner

Request for a quote

FLUKE PROCESS INSTRUMENTS GMBH

Germany

DATAPAQ temperature profiling systems comprise data loggers, thermocouples, thermal barriers, and analysis software. The DATAPAQ TP3 logger is used with DATAPAQ Furnace Tracker, DATAPAQ Kiln Tracker, and DATAPAQ Oven Tracker systems. Features: 10 or 20 thermocouple channels Reset/download via Bluetooth with short range telemetry capability (up to 5 meters) High accuracy: ±0.3 °C (±0.5 °F) Onboard memory service log for remote diagnostic and rapid on-site service Standard USB data cable available in local markets Radio frequency (RF) telemetry or hardwired data acquisition for monitoring in real time Three user-replaceable battery types for operation in normal and high ambient temperatures ‘Multiple events’ allows variable sampling intervals during a run – ideal for water and gas quench processes Multiple run capability allows storing up to 10 runs before downloading into separate .paq files Sampling intervals down to 0.1 seconds to collect maximum data

Request for a quote

FLUKE PROCESS INSTRUMENTS GMBH

Germany

Thermal imaging system based on the Raytek MP150 infrared linescanner. Detailed web temperature profile based on 40,000 measurement points per second Automated temperature monitoring Automated quality monitoring for ISO9000 Ensures proper web temperatures for strong film-to-substrate adhesion Enables plant operators to reduce scrap and improve profitability and product quality Quick and automatic detection of “wavy” or “running” edges, gaps, and torn edges Define product-specific configurations (recipes) Automatically analyze “automatic sector” temperature distributions Visualisation on PC Playback stored files as “movie” Multiple language support Integrated OPC server for remote system control Ethernet TCP/IP interface integrated in the line scanning system PC-independent alarm output Analog outputs 3 x 4 – 20mA Analog or digital output modules For sheet extrusion see the Raytek ES150 system.

Request for a quote

FLUKE PROCESS INSTRUMENTS GMBH

Germany

Kiln shell temperatures are monitored along the entire length of the kiln. The infrared line-scanning system detects kiln hot spots due to refractory loss, damage, or wear. Data from up to 4 scanners or individual point sensors (optionally used to monitor the burning zone and tire slips) can be seamlessly integrated into one complete thermal image. Detect abnormal operating conditions such as faulty flame position and shape! Optimize and manage kiln maintenance! Extend the operational life of kiln and refractory! Automated kiln and refractory monitoring Visualisation on PC Ethernet TCP/IP interface PC-independent alarm output Analog outputs 3 x 4 – 20mA To ensure reliable operation in even the harshest kiln environments, the MP150 linescanner, which is used in the CS210 thermal imaging system system, is designed with a rugged cast aluminum housing and mounted in a robust stainless-steel enclosure.

Request for a quote

FLUKE PROCESS INSTRUMENTS GMBH

Germany

Thermal imaging system based on the Raytek MP150 infrared linescanner Automatic temperature and quality monitoring in continuous web processes Detect thermal problems early Faster product changes and reduced setup time Communicate with process control system via OPC Reduce scrap APPLICATIONS Plastics, metals, paper, and building industries, combustion prevention, hotspot detection, flat and float glass production, automotive, food processing and numerous other industrial applications FEATURES Onboard Ethernet TCP/IP communication Product specific configurations or “recipes” Custom measurement sectors Optional analog and digital outputs for each sector Analog outputs 3 x 4 – 20mA PC-independent alarm output Visualisation on PC Software supports English, German, French, Finnish, Dutch and Italian languages

Request for a quote

FLUKE PROCESS INSTRUMENTS GMBH

Germany

• Real-time thermal imaging, scan speed up to 300 Hz • Up to 1024 measurement points per line • Wide choice of spectral and temperature ranges • High-quality brushless motor (MTBF 40,000 h) • Built-in Ethernet TCP/IP communications • PC independent alarm output • PC independent 4-20 mA interfaces (3 outputs) • I/O module support for up to 10 sectors/zones (PC independent) • Internal Line Laser for accurate alignment • Rugged, waterproof IP65 enclosure • Air purge keeps window free of dirt and condensation • Built-in water cooling for ambient up to 180 °C (356 °F)

Request for a quote

FLUKE PROCESS INSTRUMENTS GMBH

Germany

Dedicated temperature profiling solutions for — Anti-reflection coating & Thin-film deposition — Silicon PV manufacturing: contact drying, contact firing — Lamination Benefits — Measure product temperature uniformity across the process chamber(s) — Optimize the process by reducing energy costs and/or increasing throughput — Troubleshoot the process quickly and easily — Track process stability

Request for a quote

FLUKE PROCESS INSTRUMENTS GMBH

Germany

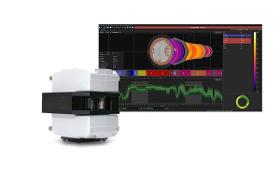

The CS400 Kiln Shell Imaging System relies on the MP Linescanner, which provides continuous, accurate and real-time thermal images and temperature measurements for moving processes. With the ability to scan up to 1024 data points in a single scan, the MP Linescanner can provide a complete picture of even the highest speed manufacturing processes, ensuring an accurate temperature reading. Key Features: — Polar charts highlighting coating thickness and brick thickness — Envelope profiles – including alarm functionality – over the entire kiln — Built-in, on-network storage to store historical data — Free scalable AOIs (areas, line and slice) including temperature trend analysis — Virtual 3D walkthroughs across the entire kiln — 3D views available per each defined kiln zone — Easy-to-use software configurations that showcase the scanner position relative to the kiln — Flexible image sizing and configurable orientations of rotation — Fail-safe “hot spot” alarm outputs

Request for a quoteResults for

Measurement - equipment & instruments - Import exportNumber of results

14 ProductsCountries

Company type