- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- fillings

Results for

Fillings - Import export

VISCOTEC PUMPEN- U. DOSIERTECHNIK GMBH

Germany

The compact 3VPHD8 Pharma Dispenser enables precise and reliable dosing of a wide variety of materials. Thanks to the special rotor-stator-geometry, no valve is required to prevent the medium from flowing out independently. Alternating opening chambers ensures gentle product transport and pulsation-free output. The VPHD series was specially developed for applications in the pharmaceutical, biotechnology, medical and food industries. Your advantages: - Interior with optimised dead space - Design according to EHEDG guidelines - FDA-compliant design/development - hygienic and pharmaceutical design - Works certificate 3.1 (DIN EN 10204) - all surfaces for pharmaceutical applications Ra ≤ 0.8 μm - retraction option (no dripping or thread pulling) - absolutely linear relationship between rotor speed and spread rate - long service life due to media-specific component selection

Request for a quote

WHITE STEEL GMBH

Germany

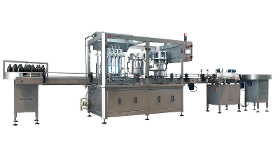

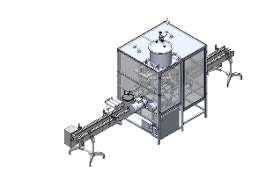

DESCRIPTION High stability on high capacity. Can handle multiple bottles size, types and shapes Type of metal used S.S 316 / 304 Certifications ISO 90012015, OHSAS 180012007, ISO 500012011, ISO 450012018 SPECIFICATION 2 heads diving filling nozzles Star capping and closing system Herma Labeling machine 1 heads One collecting table HMI and SCADA system with touch screen integrated user friendly and simplified software. Available certification up on your request UL, CE, GMP, FDA, ASME. Available documents up on your request I.Q (Installation qualification), O.Q Operational qualification), P.Q Performance qualification.

Request for a quote

WHITE STEEL GMBH

Germany

DESCRIPTION High stability on high capacity. Can handle multiple bottles size, types and shapes Type of metal used S.S 316 / 304 Certifications ISO 90012015, OHSAS 180012007, ISO 500012011, ISO 450012018 SPECIFICATION 2 heads diving filling nozzles Star capping and closing system Herma Labeling machine 1 heads One collecting table HMI and SCADA system with touch screen integrated user friendly and simplified software. Available certification up on your request UL, CE, GMP, FDA, ASME. Available documents up on your request I.Q (Installation qualification), O.Q Operational qualification), P.Q Performance qualification.

Request for a quote

WHITE STEEL GMBH

Germany

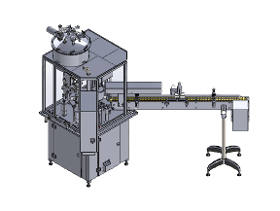

DESCRIPTION the machine has been made with a compact design. Machine can handle multiple bottles type and size. Capping and closing star system (for compact design). Servo star system. Servo closing system. Bottles Sterilization system SPECIFICATION 2 Filling nozzles Servo conveyor system included Type of metal used S.S 316 for all product contact metal parts & S.S 304 for all uncontacted product parts HMI and Scada system. Certifications ISO 90012015, OHSAS 180012007, ISO 500012011, ISO 450012018 Available certification up on your request UL, CE, GMP, FDA, ASME. Available documents up on your request I.Q (Installation qualification), O.Q Operational qualification), P.Q Performance qualification.

Request for a quote

WHITE STEEL GMBH

Germany

DESCRIPTION High stability on high capacity. Can handle multiple gallon size, types and shapes Type of metal used S.S 316 Certifications ISO 90012015, OHSAS 180012007, ISO 500012011, ISO 450012018 SPECIFICATION One gallon feeding turn table One collecting table HMI and SCADA system with touch screen integrated user friendly and simplified software. Available certification up on your request UL, CE, GMP, FDA, ASME. Available documents up on your request I.Q (Installation qualification), O.Q Operational qualification), P.Q Performance qualification. Linear filling system. 4 heads filling nozzles Sealing and capping star section.

Request for a quote

WHITE STEEL GMBH

Germany

DESCRIPTION High stability on high capacity. Can handle multiple gallon size, types and shapes Type of metal used S.S 316/304 Certifications ISO 90012015, OHSAS 180012007, ISO 500012011, ISO 450012018 SPECIFICATION Pneumomechanical Barrel feeding system Volumetric filling system One head Diving nozzles filling technology Servo conveyor system with multiple speed technology. Low to high viscosity Cut and seal system Multiple roll types can be handled. MechanicPneumatic capping system HMI and SCADA system with touch screen integrated user friendly and simplified software. Available certification up on your request UL, CE, FDA. Available documents up on your request I.Q (Installation qualification), O.Q Operational qualification), P.Q Performance qualification.

Request for a quote

WHITE STEEL GMBH

Germany

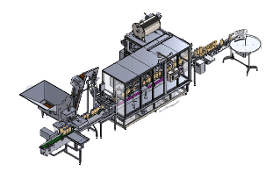

DESCRIPTION: High stability on high capacity. Can handle multiple Jar and caps size, types and shapes Type of metal used: S.S 316 / 304 Certifications: ISO 9001:2015, OHSAS 18001:2007, ISO 50001:2011, ISO 45001:2018 SPECIFICATION: 6 diving filling nozzles Customizable jar filling spaces HMI and SCADA system with touch screen integrated user friendly and simplified software. Available certification up on your request: UL, CE, GMP, FDA, ASME. Available documents up on your request: I.Q (Installation qualification), O.Q Operational qualification), P.Q Performance qualification. Linear filling system Caps feeding section with vertical conveyor system Capping system Closing system. Servo conveyor system.

Request for a quote

WHITE STEEL GMBH

Germany

DESCRIPTION compact design. made up to our German technology, to meet all the international and the European standards. One side labeling machine with coding, dating system Our machine can handle a large type of label, Bottles, and caps Types, size and shapes. SPECIFICATION Pneumatic paddle Volumetric filling system Type of metal used S.S 316 Labeling head. Pneumatic capping gun Drawer feeding caps Label coding system Mechanical weight adjustment system Certifications ISO 90012015, OHSAS 180012007, ISO 500012011, ISO 450012018 Available certification up on your request UL, CE, GMP, FDA, ASME. Available documents up on your request I.Q (Installation qualification), O.Q Operational qualification), P.Q Performance qualification.

Request for a quote

WHITE STEEL GMBH

Germany

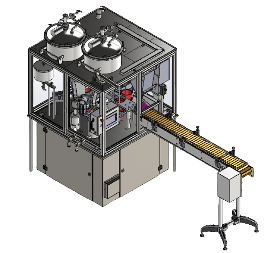

DESCRIPTION High stability on high capacity. Can handle multiple bottles size, types and shapes Type of metal used S.S 316 / 304 Certifications ISO 90012015, OHSAS 180012007, ISO 500012011, ISO 450012018 SPECIFICATION 4 diving filling nozzles One bottles feeding rotary table Star capping system Caps feeding system One collecting table HMI and SCADA system with touch screen integrated user friendly and simplified software. Available certification up on your request UL, CE, GMP, FDA, ASME. Available documents up on your request I.Q (Installation qualification), O.Q Operational qualification), P.Q Performance qualification.

Request for a quote

WHITE STEEL GMBH

Germany

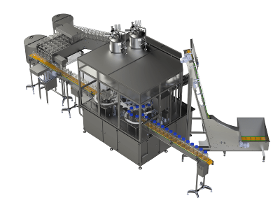

Flow meter system “ Krohne “ Double conveyor system 8 diving nozzle filling system Caps transferring vertical conveyor Vibrator caps feeder Herma double head labeling system HMI and SCADA system with touch screen integrated user friendly and simplified software. Available certification up on your request: UL, CE, GMP, FDA, ASME. Available documents up on your request: I.Q (Installation qualification), O.Q Operational qualification), P.Q Performance qualification. Linear system. Filling capping labeling machine .

Request for a quote

WHITE STEEL GMBH

Germany

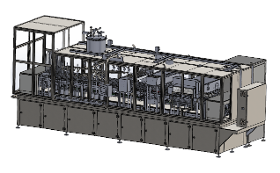

DESCRIPTION: High stability on high capacity. Can handle multiple ointment viscosity and types Type of metal used: S.S 316 / 304 Certifications: ISO 9001:2015, OHSAS 18001:2007, ISO 50001:2011, ISO 45001:2018 SPECIFICATION: Volumetric filling system SCADA and HMI with a touch screen system 2 head filling nozzle Cups feeder system Sealers feeding system Sealing system Caps feeder system Capping system UV sterilizer system Servo conveyor system Compact design Available certification up on your request: UL, CE, GMP, FDA, ASME. Available documents up on your request: I.Q (Installation qualification), O.Q Operational qualification), P.Q Performance qualification.

Request for a quote

WECKERLE MACHINES

Germany

The MultiStick is able to tailor up to 6 different forms and capable of filling up to 6000 lipsticks per hour in 24/7 operation. Thanks to the new Plug & Play Technology with the rail mounting system for process stations, the machine can be easily upgraded without major frame rework. It also offers an optimized footprint with integrated compounding. The MultiStick assures the ultimate process flexibility in the whole filling technology.

Request for a quote

NAUMANN STEPPDECKENFABRIK GMBH

Germany

Each fleece consists of many, very fine layers of gauzy material which ensure that air and thus warmth can be stored and moist can evaporate.

Request for a quote

NAUMANN STEPPDECKENFABRIK GMBH

Germany

We have different concepts to match different sleeping habits and preferences. These vary by type of filling, type of shell fabric or quilting pattern.

Request for a quote

BIZERBA SE & CO. KG

Germany

The professional filling system FSL-PRO M for companies where to-the-gram weighing and safe packaging even of flammable, foaming or corrosive liquids as well as gentle dosing are of importance. This semi-automatic machine reliably fills your already palletized containers. With a multi-interval scale you also achieve exact weighing results for large measuring ranges. The professional filling system FSL-PRO M is specifically designed for companies filling large quantities. Canisters, pails and drums are equally suitable. For easy handling, the containers are filled and weighed while standing on a pallet. The FSL-PRO M with optional additive tare allows filling of all containers with a uniform small interval from the first to the last container.

Request for a quote

BIZERBA SE & CO. KG

Germany

The fully automatic filling system optimizes your product quality by to-the-gram weighing, safe packaging even of flammable, foaming or corrosive liquids and through gentle dosing. By means of a multifunctional offset slide you benefit from maximum flexibility for container types and sizes as well as from efficient handling without retrofitting time. The fully automatic machine FSL-EVO S facilitates quick and reliable filling of high quality and sensitive products in different containers. Products can be fully automatically closed and labeled with variable data, if desired. By means of a set up buffer section the filling system largely works autonomously.

Request for a quote

BIZERBA SE & CO. KG

Germany

Filling system FSL-ECO S is the optimal entry level model for small companies who want to fill high-quality, uncritical and non-flammable liquids. With automatic filling as accurate as 1 gram this practical system lets you save time and money. FSL-ECO S offers particular advantages for companies where filling of liquid products is a firm part but not the main task in their production process. This system is the first step from manual to automatic filling. The semi-automatic system safely and reliably fills all common containers such as canisters, pails, drums or IBCs. Products are handled manually and the automatic filling provides to-the-gram results. You avoid over or underfilling and save valuable time.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

CHALLENGER INDUSTRIAL SOLUTIONS GMBH

Germany

The 200A is linear filling solutions for high and fast production needs. This heavy beast is designed to fulfill heavy-duty needs for big factories and production lines up to 24,000 unit/hour. The machines can be adjusted according to the need of the customer and may serve liquid, paste and molasses in all size ranges.

Request for a quote

CHALLENGER INDUSTRIAL SOLUTIONS GMBH

Germany

Full Automatic Machine For Filling and sealing and capping Tahini or any liquid or semi pasty products in plastic jars it’s seven working stage

Request for a quote

CHALLENGER INDUSTRIAL SOLUTIONS GMBH

Germany

the 888 is a rotary filling solutions for high and fast production needs. This heavy beast is designed to fulfill heavy-duty needs for big factories and production lines 1400-2100 unit/hour. The machines can be adjusted according to the need of the customer and may serve liquid, paste all size ranges

Request for a quote

CHALLENGER INDUSTRIAL SOLUTIONS GMBH

Germany

Challenger 506D is fully automatic mechanical linear system It’s designed for filling liquid or pasty products in plastic bucket With five work stations: Adding buckets, filling, adding covers, pressing cover, Exiting

Request for a quote

CHALLENGER INDUSTRIAL SOLUTIONS GMBH

Germany

A full automatic packaging machine that fills in plastic containers and thermally welds them. It consists of five work stages that start with pulling the empty containers, then packing, then coverings, then welding and taking out. Suitable for medium products, with a production capacity of 1500 packages per hour.

Request for a quote

CHALLENGER INDUSTRIAL SOLUTIONS GMBH

Germany

an automatic filling and packaging machine that operates in a circular system to fill liquid or semi-liquid materials with plastic containers of different sizes and shapes on demand. It consists of five stages of work, starting with pulling the empty containers, then filling them, then placing the aluminum or nylon cover, then welding with cutting and taking out through the conveyor belt. It is suitable for medium production with a productivity of 1500 packages per hour.

Request for a quote

BEHN + BATES MASCHINENFABRIK GMBH & CO. KG

Germany

For the smooth processing of your big bags we offer different machine variants allowing to fill powders & flours as reliably as grains & granules. Furthermore our delivery programme includes a large variety of accessories, e. g. automatic pallet separator, cover sheet dispenser or full pallet transport systems.

Request for a quote

BEHN + BATES MASCHINENFABRIK GMBH & CO. KG

Germany

Bag filling with the BEHN + BATES impeller packer is achieving best filling results due to low-air filling and high filling pressure

Request for a quote

BEHN + BATES MASCHINENFABRIK GMBH & CO. KG

Germany

The continuous product flow from the filling chamber is ensured by the fluidization air quantities being adjustable to your product. For compact bag shapes the special BEHN + BATES filling de-aeration nozzle removes the air from the bag already during filling.

Request for a quote

BEHN + BATES MASCHINENFABRIK GMBH & CO. KG

Germany

The continuous product flow from the filling chamber is ensured by the fluidization air quantities being adjustable to your product. For compact bag shapes the special BEHN + BATES filling de-aeration nozzle removes the air from the bag already during filling.

Request for a quote

RIEGLER & CO.KG

Germany

Pressure gauge and thermometer are suitable for the various pressure and temperature measurement applications. We offer solutions for gas and liquid measurements. The range covers capsule, plate or Bourdon-tube pressure gauges and measuring instruments made from various materials with versions extending from standard models to stainless steel versions, for use in corrosive environments, and electronics measuring equipment.

Request for a quote

SCHMITTER HYDRAULIK GMBH

Germany

Universal test - and filling equipment For bladder - , piston - and diaphragm accumulator Test - and filling equipment for filling, regulating and testing for different types of hydro ... Category Hydraulic systems, valves and components / Accumulators / Fill-in accessories Product number supplier 461101

Request for a quoteResults for

Fillings - Import exportNumber of results

172 ProductsCountries

- Germany (172)

- Bonn, Düsseldorf and North Rhine and Westphalia (25)

- Frankfurt am Main and Hesse (21)

- Hamburg and region (4)

- Hannover and Lower Saxony (6)

- Kiel and Schleswig-Holstein (3)

- Mainz and Rheinland-Pfalz (2)

- Munich, Nuremberg and Bavaria (26)

- Potsdam and Brandenburg (14)

- Saarbrücken and Saarland (1)

- Stuttgart, Freiburg and Baden-Wurtemberg (58)

- Weimar and Thuringia (12)

Company type

Category

- Bottling and filling - machinery and equipment (31)

- Automation - systems and equipment (11)

- Food industry - machinery and equipment (9)

- Bag filling machinery and equipment (8)

- Packing and packaging - machinery and equipment (8)

- Passive electronic components and printed circuits (8)

- Laboratory equipment and instruments (7)

- Pumps (7)

- Chocolates, filled (5)

- Gas extraction - systems and equipment (5)

- Cosmetics industry - machinery and equipment (4)

- Quality control and certification (4)

- Cakes and pastries, factory-baked (3)

- Condensers (3)

- Dosing pumps (3)

- Cans, drums, casks and barrels, plastic (2)

- Chemical and pharmaceutical industry - machinery and equipment (2)

- Concrete forms (2)

- Dosing - machines and equipment (2)

- Films for packaging (2)