- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- heat exchangers

Results for

Heat exchangers - Import export

ANTHERMO GMBH

Germany

Temperature control of gaseous and liquid media Flat tube heat exchangers are generally used as air / air or air / liquid heat exchangers. Flat tube heat exchangers are used where the (exhaust) air is polluted and the installation space is limited. In heat recovery in particular, there are numerous applications for flat tube heat exchangers as so-called exhaust gas / exhaust air heat exchangers. Little installation space and less pressure loss While the rows of tubes in smooth tube heat exchangers consist of round tubes, the rows of tubes in flat tube heat exchangers have a special profile (see illustration). This special tube profile offers advantages over the round profile in certain applications. Flat tube heat exchangers require less installation space than smooth tube heat exchangers with the same exchange area and are therefore also lighter.

Request for a quote

ANTHERMO GMBH

Germany

Temperature exchange between a gas and a liquid In the case of air-water heat exchangers (also called gas-water heat exchangers), there is a temperature exchange between a gas (usually air) and a liquid. Finned heat exchangers can cover various areas of application: - heating and evaporating, - cooling and condensing as well as heat recovery. In this context, lamellar heat exchangers are also called air heaters or air coolers. Air-water heat exchangers are often also used as exhaust gas heat exchangers or flue gas heat exchangers in order to recover the energy from warm or hot exhaust gases. Lamella packs for a large exchange area In order to achieve the largest possible exchange surface between the air and the medium (liquid) within the heat exchanger, lamellas or lamella packs are attached to the pipe system.

Request for a quote

ANTHERMO GMBH

Germany

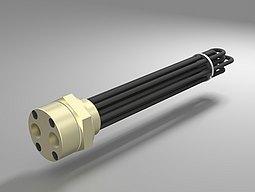

Temperature control of liquids Tube coil heat exchangers (so-called tube cooling coil heat exchangers) are generally used to control the temperature of liquids. This system can also be used to heat or cool liquids in a controlled manner. Due to their special shape, pipe coil heat exchangers are sometimes also called hairpin heat exchangers. Inexpensive applications The simple and solid structure enables it to be used in cost-effective applications. Coiled tube evaporator systems are ideally suited for brine and glycol applications. Classic variant Coiled tube evaporator systems are a classic and proven variant in the field of heat exchanger systems. Coiled tube heat exchangers are often used in ice storage systems or in the production of cold water units. In ice storage systems, coils can be used to achieve an even build-up of ice around the coils.

Request for a quote

ANTHERMO GMBH

Germany

Finned tubes for efficient heat exchange Large exchange area in a small space By using finned tubes (also known as corrugated rib tubes), optimal heat exchange can be achieved in a small space. By applying so-called ribs to smooth tubes, the exchange area of the tubes is increased considerably. Finned tubes are usually used where an optimal temperature exchange between gaseous media and liquids is to be achieved. Different designs for every purpose In many cases, finned tubes are built into production machines as a component in machine and apparatus construction. Finned tubes can be designed for a variety of special application conditions. The length, the design and the ribbing can be individually adapted.

Request for a quote

ANTHERMO GMBH

Germany

Generate cold water / flake ice continuously Proven use Falling film chillers have been used in various industrial sectors for many years. Water runs over the heat exchanger plates from a trough arranged above the heat exchanger plates. This enables a continuous heat transfer between the water and the cooling medium. Outstanding advantages The arrangement of holes in the upper tub enables targeted water distribution on the heat exchanger plates. The construction using a perforated tub has the further advantage that no contamination occurs and the liquid to be cooled is evenly distributed. Made of stainless steel The trickle cooler is made entirely of stainless steel. You can choose between different materials (see data sheet). Low boiling delay Our trickle coolers are characterized by the fact that the boiling delay is low in flooded operation, whereby overheating can be selected in dry expansion operation.

Request for a quote

ANTHERMO GMBH

Germany

Universal use for a wide range of applications Ice stores are used in more and more areas of technology. In addition to the classic areas of application in refrigeration, air conditioning and commercial kitchen technology, ice storage systems and cold water systems are increasingly being used in process engineering systems. Cold water for subsequent production processes is generated with ice storage tanks. Ice storage systems thus provide stored cold. Use of cheap night electricity tariffs With the help of ice storage technology, cheap nighttime electricity tariffs can be used. During the night, ice is continuously built up on the plates or on the pipe coils. This ice is then available during the day as stored cooling capacity. This can significantly reduce energy costs. The cooling units can also be made smaller when using ice storage systems.

Request for a quote

ANTHERMO GMBH

Germany

Know-how for special applications There are applications with very special requirements for the heat exchanger. Due to its decades of experience, Anthermo GmbH has the necessary know-how to be able to build special heat exchangers for special applications. So every year we build numerous heat exchangers that are a bit off the standard. Dimensioning with EDP programs With the help of EDP programs, Anthermo GmbH is also able to dimension and technically design special heat exchangers. The technical design and dimensioning is strictly based on the specifications and requirements of the customer. After the design, a three-dimensional CAD model is created. The CAD drawing approved by the customer forms the basis for production with the most modern IT-supported production systems.

Request for a quote

ANTHERMO GMBH

Germany

Air-water / air-air heat exchanger as smooth tube heat exchanger up to 1,000 ° C Smooth tube heat exchanger as an air / water heat exchanger In the case of air-water heat exchangers (also called gas-water heat exchangers), a temperature exchange takes place between a gas (usually air) and a liquid. As a rule, the liquid medium flows inside the pipes, while the gaseous medium flows around the pipes outside the pipes. Smooth tube heat exchangers can cover various areas of application: heating, cooling and condensing as well as heat recovery. Smooth tube heat exchanger as air-to-air heat exchanger Smooth tube heat exchangers are also often used as air-to-air heat exchangers. In this application, a gas (e.g. exhaust air or exhaust gases) flows inside the pipes and a gas (e.g. fresh air) outside the pipes around the pipes.

Request for a quote

ANTHERMO GMBH

Germany

Tubes wound into a spiral shape Coaxial heat exchangers consist of two or more pipe coils, which are routed into one another and wound up in a spiral shape. The primary medium runs in countercurrent to the secondary medium. Fast temperature exchange This countercurrent design achieves a very rapid temperature transition with high efficiency between the liquids. Due to the spiral shape, the rapid temperature exchange between the liquids is achieved in a very small space. No cleaning or maintenance required Another advantage is the encapsulation of both liquids from environmental influences. There is practically no cleaning or maintenance effort due to pollution from the environment. The coaxial heat exchanger also does not require any seals that require maintenance. Condenser or evaporator function Coaxial heat exchangers can be used for both condenser and evaporator functions.

Request for a quote

ANTHERMO GMBH

Germany

Efficient use of waste heat (up to 1.000 °C) In many production processes waste heat occurs in form of hot air which is put out to the environment without any use. Very often these hot gases are contaminated air. On the other side clean (cold) air must be warmed up for the production process. In these cases cross flow heat exchanger can reduce the energy costs. The hot air stream will be conducted in the cross or counter flow method over the cold air inside the cross flow heat exchanger. Though both air streams are strictly separated because of the construction of the heat exchanger and they don´t get mixed (leakage less than 0,5 %). Only the energy of the hot waste stream is transferred to the cold clean stream.

Request for a quote

ANTHERMO GMBH

Germany

Temperation of fluids Pillow plates are used everywhere where liquids must be temperated. In dependence of application the liquids can be cooled or heated. Cause of this wide range of applications pillow plates are used in the process industry, in the cooling industry and in a lot of other industries. Pillow plates are also know as heat exchanger plates, evaporator plates, cooling plates /sheets and thermo plates / sheets. Pillow plates as air-/water-heat exchanger Additionally to the temperation of liquids pillow plates are also used as air-/liquid heat exchangers. In case of polluted or wasted air and if there are high demands for cleaning, more and more pillow plates are used as air-/water-heat exchanger. The large exchange surface and the good possibilities for cleaning are important features for this type of heat exchanger.

Request for a quote

ANTHERMO GMBH

Germany

Air heat exchangers as finned tube heat exchangers Heat transfer between a gaseous media and a liquid Finned tube heat exchangers are often called air/water heat exchangers or gas/water heat exchangers. Heat transfer between a gas (for ex. air) and a liquid (for ex. water) takes place in the air-/water heat exchangers. To improve the thermal output transfer from the gas to the liquid, fins made of well heat transferring materials are put on the tubes. Very often air-/water heat exchangers are used as exhaust heat exchanger to gain the energy out of warm or hot exhaust fumes. Finned tube heat exchangers can also be used as air heater, air cooler or condenser.

Request for a quote

ANTHERMO GMBH

Germany

Customized air-water heat exchangers for industrial use Three types of air-water heat exchangers Three different designs o air-water heat exchangers The Anthermo GmbH delivers three different designs of air-water heat exchangers: Finned tube heat exchangers Lamella heat exchangers Straight tube heat exchangers These heat exchangers are designed in a way, that inside the tube water or another liquid circulates. The air flows around outside the tubes or the fins/lamellas. The connection between the fins and the tube is used to enlarge the space for heat transfer between the liquid and the gas fluid. The technical figures (for ex. amount of air, temperature, pressure, waste of air) can be different for the air-water heat exchanger. Also the operating conditions and the environment conditions can vary from application to application.

Request for a quote

ANTHERMO GMBH

Germany

Heat recovery with the help of heat exchangers In industry, waste heat occurs at many points in the production process, which is often released into the environment without being used. In many cases, energy is even used to cool the waste heat flows from production so that they can be released into the environment. Heat exchangers (also called heat exchangers) are used for heat recovery so that the waste heat generated in the production process can be used again in the company. Gaseous or liquid media Waste heat can be in the form of gaseous media (e.g. warm exhaust air, steam, exhaust gases, etc.) or in the form of liquid media (e.g. hot water or other liquids). With the help of heat exchangers, the waste heat can be recovered from both gaseous and liquid media and then made available to the production process at a suitable point as energy in gaseous or liquid media. This process is known as energy recovery or also as heat recovery.

Request for a quote

ANTHERMO GMBH

Germany

Customized air-air heat exchanger for the industry (up to 1.000°C) Hot outgoing air and cold incoming air Very often hot exhaust gas gets out in the environment without any use. On the other hand cold incoming air must be lead into the production process and shall be warmed. This occurs for example very often within drying technology. In this case air-air heat exchangers can be used very efficient in heat recovery. As result you have great potential to save energy expenses. Three types of air-air heat exchangers The Anthermo GmbH delivers three types of different air-air-heat exchangers: cross-flow heat exchanger straight-tube heat exchanger flat-tube heat exchanger The technical figures (for ex. amount of air, temperature, pressure, waste of air) can be different for the air-air heat exchanger. Also the operating conditions and the environment conditions can vary from application to application.

Request for a quote

APROVIS

Germany

* High-temperature heat exchangers * Gland steam condensers

Request for a quote

R+L HYDRAULICS GMBH

Germany

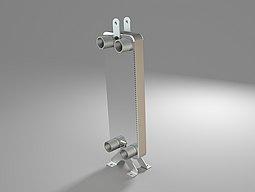

Efficient cooling Extremely compact Inexpensive solution Cooling surface 0,15 0,43m2 Easy assembly

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

APROVIS

Germany

What you can expect from APROVIS high-temperature heat exchangers: - Transfer to water / thermal oil / air - Abrasion protection for abrasive components in the flue gas or product gas (e.g. wood gas) - Implementation of individual solutions (e.g. with regard to available space, thermal performance) - Use of various high-temperature stainless steels according to the application in question - Own measurements on site

Request for a quote

APROVIS

Germany

What you can expect from APROVIS exhaust gas heat exchangers: - Efficient hot water generation in combined heat and power plants - Heating of thermal oil as an energy source - Individual solutions and compact designs - All the main components for the exhaust gas section and gas treatment are combined under one roof: proprietary products developed in-house - Cost-saving and reliable operation of the systems - Maximum functionality, safety and service - Temperature ranges: up to 600°C on the exhaust gas side or up to more than 1,000°C in the high-temperature range - Maximum functionality, safety and service - Temperature ranges: up to 600°C on the exhaust gas side or up to more than 1,000°C in the high-temperature range - Certifications: PED 2014/68/EU, ASME Code, EAC - Can be used in all plants with exhaust gases from hydrogen, natural gas, biogas, sewage gas and special gases, plus diesel and other liquid fuels - Geared to international standards and directives

Request for a quote

APROVIS

Germany

* Exhaust gas heat exchangers * Steam generators * Silencers * Oxidation and three-way catalytic converters * SCR catalytic converters/Diesel SCR catalytic converters * Diesel particulate filters * Chimneys

Request for a quote

WOMA GMBH

Germany

This high pressure water jetting unit is extremely flexible due to its usage as a trailer. Three versions of the MK3 with operational pressure of up to 2500 – 3000 bar are available and is ideal for the removal of coating and concrete refurbishment, as well as for the separation and cutting of various materials. The easy to understand WOMATIC 4Control with operational status monitoring, pressurerpm regulation and pressureless circulation ensures high operational safety, low wear and tear, long service life, and last but not least, minimal fuel consumption.

Request for a quote

WOMA GMBH

Germany

The EcoMaster D 1502 Classic is ideally suited to the external cleaning of tanks up to the removal of dirt and corrosion, for example, as well as the removal of coating. All Classic devices are fitted with robust, low maintenance and strong performance WOMA high pressure pumps. The compact design with stable frame construction enables easy usage in difficult areas. Fitted with crane hooks a simple transportation is guaranteed. Effortless regulation via optional manual pressure control or Dump Gun is possible and the large water tank ensures a calm water cycle. The Ecomaster Clasicseries brings a very good price performance ratio thanks to functional construction and proven mechanical components combined with low operational costs due to high service life, minimal maintenance costs and simple servicing.

Request for a quote

WOMA GMBH

Germany

The EcoMaster D 2502 Classic is ideally suited to the external cleaning of tanks up to the removal of dirt and corrosion, for example, as well as the removal of coating. All Classic devices are fitted with robust, low maintenance and strong performance WOMA high pressure pumps. The compact design with stable frame construction enables easy usage in difficult areas. Fitted with crane hooks a simple transportation is guaranteed. Effortless regulation via optional manual pressure control or Dump Gun is possible and the large water tank ensures a calm water cycle. The Ecomaster Clasicseries brings a very good price performance ratio thanks to functional construction and proven mechanical components combined with low operational costs due to high service life, minimal maintenance costs and simple servicing.

Request for a quote

WOMA GMBH

Germany

The EcoMaster D 150M Classic offers the optimal equipment for the refurbishment and removal of concrete or coating, as well as for the separation and cutting of various materials. All Classic devices are fitted with robust, low maintenance and strong performance WOMA high pressure pumps. The compact design with stable frame construction enables easy usage in difficult areas. Fitted with crane hooks a simple transportation is guaranteed. Effortless regulation via optional manual pressure control or Dump Gun is possible and the large water tank ensures a calm water cycle. The Ecomaster Clasicseries brings a very good price performance ratio thanks to functional construction and proven mechanical components combined with low operational costs due to high service life, minimal maintenance costs and simple servicing.

Request for a quote

WOMA GMBH

Germany

The application fields of the EcoMaster D 150Z Classic are the internal cleaning of tanks, containers or autoclaves, as well as the cleaning of large pipes. All Classic devices are fitted with robust, low maintenance and strong performance WOMA high pressure pumps. The compact design with stable frame construction enables easy usage in difficult areas. Fitted with crane hooks a simple transportation is guaranteed. Effortless regulation via optional manual pressure control or Dump Gun is possible and the large water tank ensures a calm water cycle. The Ecomaster Clasicseries brings a very good price performance ratio thanks to functional construction and proven mechanical components combined with low operational costs due to high service life, minimal maintenance costs and simple servicing.

Request for a quote

WOMA GMBH

Germany

For particularly stubborn dirt and residue in the industry, which is often found in heat exchangers, sieves, filters and pipes, the EcoMaster D 250Z Classic is proven to operate with up to 1500 bar. All Classic devices are fitted with robust, low maintenance and strong performance WOMA high pressure pumps. The compact design with stable frame construction enables easy usage in difficult areas. Fitted with crane hooks a simple transportation is guaranteed. Effortless regulation via optional manual pressure control or Dump Gun is possible and the large water tank ensures a calm water cycle. The Ecomaster Clasicseries brings a very good price performance ratio thanks to functional construction and proven mechanical components combined with low operational costs due to high service life, minimal maintenance costs and simple servicing.

Request for a quote

R+L HYDRAULICS GMBH

Germany

Working pressure up to 30bar Temperatur up to 195 °C Maximal 300 plates Various brackets Special versions on demand

Request for a quote

BORSIG GMBH

Germany

BORSIG has been producing scraped surface exchangers for more than 90 years. Modern design, orientated towards practical application, state-of-the-art manufacturing and testing methods and the staff‘s expertise add up to a high-quality scraped surface exchanger that fulfils all requirements in terms of stability, operating reliability and long service life. Scraped surface exchangers are supplied almost exclusively as compact units, so that installation work on site is reduced to a minimum.

Request for a quote

BORSIG GMBH

Germany

Transfer Line Exchangers (tunnelflow and linear quench coolers) from BORSIG are used in plants producing ethylene, an important starting material for plastics manufacturing. In these ethylene plants our transfer line exchangers are rapidly cooling down the so-called cracked gas in order to obtain the optimum yield of ethylene. BORSIG Transfer Line Exchangers are the result of more than 50 years experience and about 7,500 units have been supplied worldwide between 1965. BORSIG Process Heat Exchanger GmbH has developed two design types of quench coolers, reflecting the customer`s plant concept: 1. "Tunnelflow" transfer line exchangers (shell & tube design) 2. BORSIG "Linear" transfer line exchangers (double-pipe design)

Request for a quoteResults for

Heat exchangers - Import exportNumber of results

104 ProductsCountries

Category

- Heat exchangers (82)

- Gas and oil - exploitation (20)

- Oiling - machines and systems (7)

- Refrigeration plants and equipment, commercial and industrial (7)

- Diesel engines (6)

- Boilers, industrial (2)

- Heat recovery systems (1)

- Aluminium alloys (1)

- Construction machinery (1)

- Cooling tanks (1)

- Food industry - machinery and equipment (1)

- Testing equipment (1)

- Waste water recycling (1)