- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- handling - machines & equipment

Results for

Handling - machines & equipment - Import export

OTTO BIHLER MASCHINENFABRIK GMBH & CO. KG

Germany

Specifications: Part size: max. 50 x 50 x 50 mm Part weight: max. 80g / part Bunker volume: 10 – 50 litres (depending on parts) Feeding speed: max. 30 m/min. (depending on part geometries)

Request for a quote

ZS-HANDLING TECHNOLOGIES GMBH

Germany

With the LeviWafer-Gripper Transport system it is possible, to lift and transport sensitive Wafers contactless. In combination with the transport, (un)loading of stacks and cassettes is also possible. The gripper uses ultrasonic bearing technology to keep the wafer at a distance, thus enabling contactless transport. In addition to micro-scratches and -cracks, contamination by particles is avoided since without compressed air no air turbulence is created. Therefore, the gripper is also very suitable for clean rooms. The LeviWafer-Gripper can be designed with a single or double paddle. Features of the LeviWafer-Gripper: - Contactless pickup - No micro-scratches, micro-cracks, or particles - Suitable for standard cassettes - Low energy consumption - Customizable according to customer specifications

Request for a quote

ZS-HANDLING TECHNOLOGIES GMBH

Germany

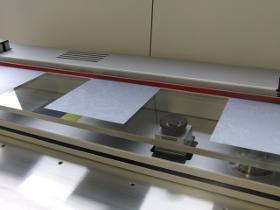

The LinearLevi-Conveyor enables the contactless transport of sensitive materials and prevents micro-scratches as well as contamination. With the LinearLevi-Conveyor, the workpieces can be guided along defined lines, without any points of contact and without the use of compressed air. Due to the Ultrasonic Suspension Technology, the substrate is kept at a distance, which prevents micro-scratches and contamination. During the transport, a high flatness also on flexible substrates is provided. Features of the LinearLevi-Conveyor: - High flatness of the workpiece - Possibility of heating or cooling sections - No compressed air necessary - Available in different lengths - Customizable according to customer specifications

Request for a quote

ZS-HANDLING TECHNOLOGIES GMBH

Germany

The LinearLevi-Inspectionmodule enables the inspection of substrates during the contactless transport. It is possible to check the quality of battery cells, foils, packaging, as well as wafers and chips without interrupting the transfer process. There is the opportunity to subsequently sort the substrates according to the inspection results. The application can be delivered in different versions. For example, combinations with the UltraLevi-Desk for contactless transport are possible. Features of the LinearLevi-Inspectionmodule: - Extendable - Various sizes - No particles due to no air turbulence - Double-sided inspection possible - High flatness, also for flexible substrates - Customizable according to customer specifications

Request for a quote

ZS-HANDLING TECHNOLOGIES GMBH

Germany

With the LinearOverhead-Transportsystem it is possible to lift and transport sensitive materials contact-free from above. The LinearOverhead-Transport-System uses negative pressure together with ultrasound, which enables contactless linear transport of components on the top side. With this system, the workpieces can be lifted from above and guided along defined lines. Besides the linear transport, the topside conveyor can be combined with other systems to provide inspecting and sorting, as well as singulation of the substrate. Features of the LinearOverhead-Transportsystem: - Contactless overhead lifting - No damage of the substrate - No air turbulences - Available in different lengths - Customizable according to customer specifications

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

ZS-HANDLING TECHNOLOGIES GMBH

Germany

The OptoMicroMed-Gripper supports the medical technology, especially the manufacturing of lenses. Our product is able to grip and deposit intraocular lenses without contact. Lifted by a combination of vacuum and ultrasound, the lens is held contactless on the bottom of a special designed sonotrode tip. This prevents micro-scratches and contamination. Besides from gripping and (un)loading, the gripper can be used for sorting and singulating. Features of the OptoMicroMed-Gripper: - Suitable for different diopters - Customizable according to customer specifications - Compatible with all robot systems - Suitable for clean rooms

Request for a quote

ZS-HANDLING TECHNOLOGIES GMBH

Germany

With the RobotOverhead-Gripper it is possible to lift sensitive materials contactless from above by means of a robot. Besides from gripping, it can be used for (un)loading, sorting and singulating. The RobotOverhead-Gripper uses a combination of negative pressure and the Ultrasonic Suspension Technology to enable topside gripping of the workpiece. The substrate is kept at a distance, which enables contactless transport and prevents micro-scratches and contamination. Our technology allows a high flatness of the substrate during the handling process. The RobotOverhead-Gripper is suitable for battery cells, glasses, foils, lenses, packaging, wafers and other sensitive materials. It can be supplied in various versions, for example for the contactless transport of glass components in the manufacture of flat screens. Features of the RobotOverhead-Gripper: - Contactless topside gripping - High flatness of the substrate - Different dimensions - Safety hooks can be fitted as an option

Request for a quote

ZS-HANDLING TECHNOLOGIES GMBH

Germany

With the Levi RollToRoll-Transport Lines it is possible to lift, redirect and transport sensitive and flexible glass, foils and packaging. Our technology generates a thin air film between the substrate and the surface of the roll, which allows the contactless roll-to-roll transport of workpieces. Therefore, micro-scratches and contamination can be prevented. The application can be delivered in different versions. For example, combinations with the UltraLevi-Desk for contactless transport are possible. The system also allows the inspection of substrates. Features of the LeviRoll: - Contactless transport - Different lengths available - Adjustable web tension - Customizable according to customer specifications, for example with inspection systems

Request for a quote

ZS-HANDLING TECHNOLOGIES GMBH

Germany

With the UltraLevi-Desk it is possible to transport and (un)load substrates without contact. Our patented technology makes the workpieces float on the surface of the ultrasonic table. The substrate is kept at a distance, which prevents micro-scratches and other damage. By avoiding compressed air and thus air turbulence, particle contamination can also be prevented. Furthermore, high flatness of the substrate is guaranteed, also for flexible materials. The UltraLevi-Desk can be combined with other systems and can be realized with or without additional drive. Features of the UltraLevi-Desk: - No damage or particles - High Flatness of the substrate - Extendable - Recesses for inspection systems or cutting units - Customizable according to customer specifications

Request for a quote

MICRO-EPSILON

Germany

Laser distance sensors are designed for non-contact distance measurements: laser gauges for measuring ranges up to 10m, laser distance sensors for up to 270m. These sensors are used for positioning and type classification in machine building and handling equipment.

Request for a quote

VISCOTEC PUMPEN- U. DOSIERTECHNIK GMBH

Germany

▪ Automated emptying system for containers up to approx. 30 liters ▪ Volumetric conveying progressive cavity pump based on the endless piston principle ▪ Pulsation-free and precise emptying and material supply to 1C and 2C dispensing systems ▪ In redundant dosing systems applicable ▪ For medium to high viscosity materials ▪ For structure sensitive, filled, abrasive materials ▪ Application for cylindrical or slightly conical metal and plastic containers ▪ Housing for machine safety and protection against dirt contamination ▪ Automatic retraction and venting the container as well as detection of media surface ▪ 4“-Touch panel with function keys for comfortable setting and parametrization of the system ▪ Externally controllable via Profinet interface ▪ Continuous determination of the position of the follower plate and level monitoring ▪ Adjustable pressure reduction for longer pauses

Request for a quoteResults for

Handling - machines & equipment - Import exportNumber of results

12 ProductsCompany type