- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- machines and equipment

Results for

Machines and equipment - Import export

VISCOTEC PUMPEN- U. DOSIERTECHNIK GMBH

Germany

The ViscoTec dosing and filling pump RD-Hygiene for food and cosmetics is a volumetric pump based on the continuous piston principle. It is ideally suited for discontinuous or continuous pulsation-free dosing of viscous, structure-sensitive and solids-laden media. Thanks to the high-quality ViscoTec dispensers, high-precision dosing applications can be realized in the food and cosmetics sector. The systems are used e.g. in the bakery and confectionery sector for decoration. Typical doses are icing or fondant, but also fillings such as vanilla or chocolate cream. Your advantages: - Specially adapted filling tubes for a wide variety of filling applications - Application and dosing in automated systems - Low to high viscosity as well as abrasive, shear-sensitive or lumpy media - hot and cold filling - Optimum results for CIP/SIP (Cleaning in Place/Sterilisation in Place) cleaning

Request for a quote

VISCOTEC PUMPEN- U. DOSIERTECHNIK GMBH

Germany

The ViscoMT-L 3 / 18 barrel emptying system offers a modern way of emptying containers.The connection with the ViscoTec VMP dispenser series for the removal of the medium offers the following advantages: - container sizes from approx. 50 l to 300 l - viscosities of approx. 80,000 - 2,000,000 mPas - very low shear stress of the medium - very low pressure load of the medium (max. 18 bar) - removal of materials loaded with fillers - no backflow within the sampling pump - electrical control of the pump with pressure control - valve-free pump system - no material pressure reducer necessary due to electronic pressure adjustment - very good residual emptying (less than 1% residue) - electronic "empty" and "almost empty" message Application: Removal of materials directly from the delivery container, e.g. silicones, adhesives, resins, greases, colour pastes, metal-filled pastes (Cu and Ni solder pastes, Al and Ag pastes) - supply of media to dispensers

Request for a quote

VISCOTEC PUMPEN- U. DOSIERTECHNIK GMBH

Germany

The ViscoMT-XM barrel emptying system with volumetric pump based on the endless piston principle. Your advantages: - for medium to high viscosity products (up to 7,000,000 mPas) - suitable for abrasive, shear-sensitive or lumpy materials loaded with fillers - clean wiping of the inside wall of the barrel due to follower plate with special sealing lip - suitable for cylindrical, ribbed or slightly conical barrels, plastic containers or containers with inliners - no lateral squeezing of the medium, as the follower plate is guided almost without pressure - discharge speed electronically adjustable - easy handling - pulsation-free conveyance/discharge - Residual quantity in the barrel: < 1% - compact design Application: Withdrawal of products directly from the delivery or storage container, e.g.: Tomato paste, honey, fats, icing, mascara and much more. pressure-controlled or level-controlled feeding of the products to filling machines or mixing processes.

Request for a quote

VISCOTEC PUMPEN- U. DOSIERTECHNIK GMBH

Germany

▪ Modular setup with five different available dispenser sizes on each side ▪ Static mixing of two materials with same or different viscosities ▪ Adjustment of the desired mixing ratio by adjusting the speed ratio of both dispensers ▪ Volumetric dosing, regardless of viscosity ▪ For low to high viscosity materials ▪ Particularly suitable for abrasive, filled or shear sensitive materials ▪ Continuous dosing, pulsation free ▪ Interior non-stick coated ▪ Linear relation between dosing volume and rotation speed ▪ Programmable suck-back prevents dripping or stringing of product ▪ Different rotor and stator materials available as standard ▪ Long service life due to application-specific rotor-stator combinations ▪ Easy cleaning and maintenance due to quick assembly and disassembly options ▪ Mixing ratio 1:1 - 100:1 ▪ Volume flow of 0 - 1,300 ml/min (depending on mixing ratio, material and dispenser combination)

Request for a quote

MAHLO GMBH & CO. KG

Germany

Keeps web safely on track Drifting of the product web lateral to the running direction of product is unavoidable in some stages of textile finishing. The Ceremat system brings the product back on the right path. Applicationspecific variants are available.

Request for a quote

MAHLO GMBH & CO. KG

Germany

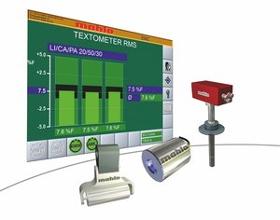

Portable moisture meter The Textometer DMB is a mobile handy device for measuring moisture on textile webs and bobbins on a wide variety of versions. It determines the moisture content of raw materials, semi-finished products and finished products precisely and quickly.

Request for a quote

MAHLO GMBH & CO. KG

Germany

Pattern and distortion control The leading pattern detection system using camera technology. The repetitions of printed, woven or tufted patterns are evaluated according to certain algorithms and are used for measuring, correcting and evaluating distortions and patterns. The system uses one or two cameras, depending on the width of the product, to detect the position of the pattern and automatically and continuously determine the pattern repeat, as well as the product width, and together with a straightening machine align the product distortion based on the recognized pattern.

Request for a quote

MAHLO GMBH & CO. KG

Germany

Infrared pyrometer The Thermosense HP270 is used for non-contacting temperature measurement in driers and stenters and records the temperature of running product webs. The sensor is temperature-resistant up to 270 °C. It can therefore be mounted inside driers.

Request for a quote

MAHLO GMBH & CO. KG

Germany

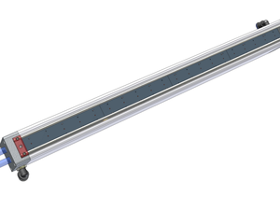

Ionisation of the air The Antistat AMW ioniser for trouble-free processing of synthetic materials and of textiles with high charge separation. By ionising the ambient air, the electrostatic charge is diverted from the product sheet. Antistat AMW can be used at high or low speeds.

Request for a quote

MAHLO GMBH & CO. KG

Germany

Condensate temperature control The Atmoset SMT regulates the residual moisture of the tissue with steam-heated cylinder dryers. The deviation of the condensate temperature from a preset setpoint is used to directly calculate the amount of energy required for drying. The heating output is optimised according to the product. The Atmoset SMT enables a stable and effective drying process. The optimal degree of drying is always reached, regardless of the weight of the product or the web speed.

Request for a quote

MAHLO GMBH & CO. KG

Germany

Reflexion of infrared light Automatic width measurement on a running product web. IR LEDs used in reflective mode continuously and precisely determine the product width. The sensor module only needs to be attached on one side of the product. The compact design allows it to be installed even in the tightest mounting spaces. Retrofitting is possible virtually anywhere.

Request for a quote

MAHLO GMBH & CO. KG

Germany

Control of thread density / course density / basis weight The Famacont PMC determines the thread density by means of a non-contacting, optoelectronic or imaging process. With the optoelectronic process individual threads or courses pass the sensor and are projected onto the photocell using a precision optical lens. The resulting frequency is proportional to the thread count. A high-resolution camera is used with the imaging process. The image is analysed with using suitable software (FFT analysis). Both, the thread count in weft and warp direction can be determined here with maximum precision.

Request for a quote

MAHLO GMBH & CO. KG

Germany

Optimizes drying The Ecopac EMC uses the state of the art microprocessor technology to ensure product quality and optimise the energy balance for drying processes. The modular system for monitoring and controlling residual moisture, product temperature, dwell time and exhaust air humidity can be flexibly adapted to current production. Up to three of the same or different modules may be used as needed. This increases quality while saving resources and energy. The modular design of the system allows its flexible adaptation to all applications. Both, standard requirements and highly customized demands are thus met.

Request for a quote

MAHLO GMBH & CO. KG

Germany

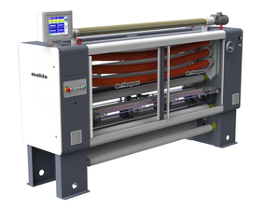

Removing all types of distortions The fusion of pin wheel and roller straightening technology perfectly combines the advantages of both technologies and provides amazing straightening results. It provides reliable, quick distortion correction also for asymmetric web distortion. An infinitely variable unclipping roller minimises residual bow and edge distortions. The intelligent drive station with special voltage control for smallest product distortion activates or deactivates automatically (e.g. in case of blockages). A bypass function is available at the push of a button for products that cannot be straightened with the pin wheel.

Request for a quote

MAHLO GMBH & CO. KG

Germany

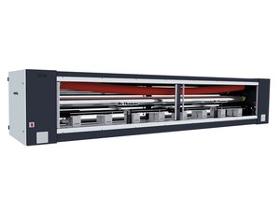

When the going gets rough ... The Orthopac CRVMC is especially designed for high mechanical load. Thanks to reinforced components, it is ideal for processing very heavyweight and wide materials. The arc of contact of the straightening rollers thereby depends on the desired straightening effect. With products without skews and bows, the straightening rollers are not enveloped unnecessarily. When the straightening rollers engage with the product, the uniform contact of the straightening rollers with the product is ensured over the entire width. This becomes possible through our innovative and unique roller positioning drive.

Request for a quote

MAHLO GMBH & CO. KG

Germany

Heavy-duty weft straightening The heavy duty version. High demands due to large product widths (e.g. carpet) or dimensionally stable textiles with defined skew settings (e.g. denim) require a more solid configuration. The frame, bearings and rollers are designed for high loads. Available with up to 5400 mm working width.

Request for a quote

MAHLO GMBH & CO. KG

Germany

Fine-tune straightening for heavyweight fabrics The special strength of the Orthopac GMFRC is the extremely high straightening accuracy at relatively small distortions. Thanks to reinforced components, it is ideal for processing really wide, heavyweight materials such as denim. The compact straightening unit is equipped with a skew and bow roller as standard. This arrangement allows for very fine adjustment of the straightening effect while permitting small device dimensions.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

MAHLO GMBH & CO. KG

Germany

Bow and skew detection and control The Orthopac FMC automatic straightener is the heart and core of the Orthopac. The device consists of an optical scanning system and electronic control for distortion correction. It is used primarily to detect and log residual distortions in the exit end of a system, e.g. with the stenter. Thread density can be determined at the same time. It can also be connected to external straightening machines then serving them as control unit.

Request for a quote

MAHLO GMBH & CO. KG

Germany

Weft straightening the way it should be ... The Orthopac RVMC is the universally employable straightening system from Mahlo for the correction of web distortions for nearly all applications. Available with hydraulic or electrical straightening roller adjustment. The modular construction allows the system to be configured to meet the demands of changing conditions and requirements.

Request for a quote

VISCOTEC PUMPEN- U. DOSIERTECHNIK GMBH

Germany

▪ Continuous volumetric and pulsation-free dosing regardless of viscosity ▪ For low viscosity and self-levelling materials (e.g. trickle resins) ▪ Low wear solution due to avoidance of material contact at shaft seal ▪ Uninterrupted production thanks to material reservoir with up to 350 ml usable volume ▪ Pressure and temperature sensor including sensor holder at pump outlet ▪ Level programmable using analog level sensor ▪ Filling under atmospheric pressure ▪ Optional connection for process gas (max. 0.2 bar pressure) ▪ Dispenser holder for easy and stable installation ▪ Increased process reliability due to integrated safety device ▪ Dividable rotor assembly for easy & fast replacement and low spare part costs

Request for a quote

VISCOTEC PUMPEN- U. DOSIERTECHNIK GMBH

Germany

▪ Automated emptying system for containers up to approx. 30 liters ▪ Volumetric conveying progressive cavity pump based on the endless piston principle ▪ Pulsation-free and precise emptying and material supply to 1C and 2C dispensing systems ▪ In redundant dosing systems applicable ▪ For medium to high viscosity materials ▪ For structure sensitive, filled, abrasive materials ▪ Application for cylindrical or slightly conical metal and plastic containers ▪ Housing for machine safety and protection against dirt contamination ▪ Automatic retraction and venting the container as well as detection of media surface ▪ 4“-Touch panel with function keys for comfortable setting and parametrization of the system ▪ Externally controllable via Profinet interface ▪ Continuous determination of the position of the follower plate and level monitoring ▪ Adjustable pressure reduction for longer pauses

Request for a quote

VISCOTEC PUMPEN- U. DOSIERTECHNIK GMBH

Germany

Our ecoPEN XS is a true volumetric dispensing system that applies the smallest amounts of singlecomponent fluids – for highprecision dispensing technology. Thanks to the proven endless piston principle, watery to pasty liquids are perfectly dispensed. A clean, processreliable dosage is achieved regardless of fluctuations in viscosity. - Dimensions (without cartridge and holder): length 178 mm, width 22 mm, depth 65 mm - Weight (without cartridge and holder): 175 g - Operating pressure: 0 - 6 bar - Max. dispensing pressure: 20 bar - Self-sealing: Approx. 2 bar - Viscosity: watery to pasty - Volume flow: 0.0044 - 0.35 ml/min - Min. dispensing quantity: 0.25 µl - Dosing accuracy: ± 1% - Stator material: vidur-C1 - Material inlet: Luer-Lock adapter for cartridge (cartridge can be rotated 360°) / Adapter for hose connection (Ø - 3mm) - Material outlet: Luer-Lock (patented) - Wetted parts: POM / vidur-C1 / stainless steel / HD-PE - Repeatability: > 99 %

Request for a quote

VISCOTEC PUMPEN- U. DOSIERTECHNIK GMBH

Germany

▪ Intermittent recording and storage of one or two pressure signals ▪ Evaluation of pressure signals using previously defined limit curves/ranges (“teach in”) ▪ Easy and intuitive operation ▪ 5” colour touch screen ▪ Voltage signal processing (0 – 10 V) ▪ Compatible with flowplus16 and flowplus-SPT M6 ▪ Easy assembly (plug & play and start up) ▪ Data backup with USB stick possible

Request for a quote

MAHLO GMBH & CO. KG

Germany

Removing irregular distortions Asymmetrical distortions (wavy, S-shaped, etc.) in textiles have always represented a huge challenge in the textile industry. A special straightening approach is needed particularly when the straightening process does not take place in combination with a stenter (e.g. before decatizers, digital printing systems, etc.). To restore the warp and weft threads to their original state, the Orthofact RMB generates a defined lateral tension using freewheeling, inclined pin wheels. This cross-tension stretches the warp threads. The resultant force controls the freewheeling pin wheels, since the weft threads will always seek out the shortest path from selvedge to selvedge. Distortion, no matter whether wavy or S-shaped, will be corrected.

Request for a quote

MESUTRONIC GMBH

Germany

TUNNEL METAL DETECTOR WITH INTEGRADTED EVALUATION ELECTRONIC -USED IN BELT CONVEYORS FOR QUALITY CONTROL OR MACHINE PROTECTION. Detects all metals encapsulated or as loose parts. The new performance benchmark! imagePHASE visualizes your product and is a synonym for highly accurate metal detection at maximum reliability. Impressive simple operation. Minimal floor space required (reduced metal-free area) due to mesuCAGE technology. Compliant with quality assurance according to HACCP, IFS, BRC, SQF. Specifically tailored system solutions with reliable conveying technology and selected accessories.

Request for a quote

K-TECH ELECTRONIC VERTRIEBS GMBH

Germany

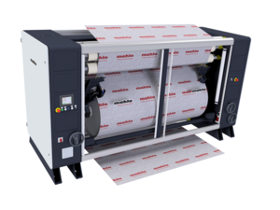

Counting and marking the components of an open reel allows inventory management with maximum accuracy. The enormous advantage of printing on the cover t ape lies within the lack of necessity for more than one counting per reel. Never recount another reel. SMARTcount is a reliable, fast, easy to operate machine with high performance. SMARTcount is designed to code reels of SMD components to enable stores personnel to quickly and accurately gauge the quantity of product remaining on a reel. The machine is used to unwind a reel of components, then rewind it printing a component count onto the cover tape as it rewinds. Increase stock count accuracy with the elimination of manual counts Reduce material handling and machine changeover times Eliminate disruptions in daily production line operation

Request for a quote

BAUSHOP EXPRESS GMBH

Germany

The Husqvara K 770 is a powerful all-round cut-off machine with features that make it one of the best cut-off machines on the market.The semi-automatic SmartTension ™ system enables optimal power transmission, minimal wear and maximum belt life. The light weight, outstanding power-to-weight ratio, reliable starting mechanism and exceptionally low vibration mean less stress and maximum productivity. SPECIFICATIONS: ENGINE: Output power: 3.7 kW Max. recommended speed: 9,300 rpm Speed at max. output: 9,000 rpm Cylinders: 1 Number of strokes: 2-stroke engine Exhaust emissions (CO2 EU V): 711 g/kWh Power source: Petrol CUTTING EQUIPMENT: Max. Cutting depth: 125 mm Max. Cutting disc diameter: 350 mm Pick up diameter: 20/25,4 mm Max. Cutting disc thickness: 5 mm Max. speed: 90 m/s Coolant: Wet

Request for a quote

BAUSHOP EXPRESS GMBH

Germany

The F-Line - the perfect compulsory mixer for every application, meeting your requirements optimally and economically. Advanced technology, for performance and environmentally friendly operation. The standard gearbox runs at 32U/m, with the Vario gearbox the revolutions can be varied between 9 - 55 U/m. The highlights at a glance: - Powerful and very robust motor/gearbox. - Optimal performance and easy handling - Easy cleaning and maintenance - Fast, effective mixing with large capacity - Optimal mixing functions BARON F-120: - Safety circuit when lid is opened - Position bolt for lid safety during use - Motor protection prevents contamination - Simple and efficient operation - Adjustable mixing blades - Optional rubber blades Attention!!! In order to be able to connect the unit to a normal Schuko socket, the CEE to Schuko adapter must also be ordered under the Optional accessories tab.

Request for a quote

BAUSHOP EXPRESS GMBH

Germany

Bomag BT 65 rammer for frequent use Fields of application: - Earthwork and asphalt construction. Pipe and conduit construction - Trench and canal construction, backfilling, foundations and repair work on asphalt. For frequent use with the highest demands on compaction results and efficiency. - Most powerful rammer in its class - Proven Honda 4 -stroke engine - Optimized full engine protection - Double air filter system - Hour meter and tachometer - On/Off safety switch for simultaneous switching on and off of engine and fuel supply in one hand movement Incl. 3-2-1 original Bomag warranty!

Request for a quoteResults for

Machines and equipment - Import exportNumber of results

53 ProductsCompany type

Category

- Textiles - Machines & Equipment (20)

- Construction - Machines & Equipment (11)

- Handling - Machines & Equipment (10)

- Dosing - machines and equipment (8)

- Dosing pumps (4)

- Metals - Machines & Equipment (2)

- Bottling and filling - machinery and equipment (2)

- Food Industry - Machines & Equipment (1)

- Paper - Printing - Machines & Equipment (1)