- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- textile finishing

Results for

Textile finishing - Import export

MAHLO GMBH & CO. KG

Germany

Compressed air blade To monitor the progress of certain processes, there is no alternative but to take frequent samples at the machine itself. This is normally possible only while the product is either moving slowly or stopped, and often results in complicated work-arounds to enable continual production (continuously running winders, etc.). The Samplecut FSC is the solution to the problem. The tried and tested sample cutter Samplecut FSC takes samples from fast running product.

Request for a quote

MAHLO GMBH & CO. KG

Germany

Keeps web safely on track Drifting of the product web lateral to the running direction of product is unavoidable in some stages of textile finishing. The Ceremat system brings the product back on the right path. Applicationspecific variants are available.

Request for a quote

MAHLO GMBH & CO. KG

Germany

Control room application mPilot is a control room application for Mahlo equipment. The software allows the user to configure up to ten Mahlo devices with one control centre. Individually selected data of several devices are clearly arranged. The innovative control tool supports production and shift managers in handling their daily business as efficiently as possible. Key elements Display of running processes of up to ten Mahlo machines Job control (configure jobs and recipes) Configuration of product lines and machines Alarm management (current and historical warnings) Various communication protocols (OPC UA, OPC DA, Modbus TCP, Profibus, Profinet, Ethernet/IP) Start of predefined jobs (only with mCockpit)

Request for a quote

MAHLO GMBH & CO. KG

Germany

Optimizes drying The Ecopac EMC uses the state of the art microprocessor technology to ensure product quality and optimise the energy balance for drying processes. The modular system for monitoring and controlling residual moisture, product temperature, dwell time and exhaust air humidity can be flexibly adapted to current production. Up to three of the same or different modules may be used as needed. This increases quality while saving resources and energy. The modular design of the system allows its flexible adaptation to all applications. Both, standard requirements and highly customized demands are thus met.

Request for a quote

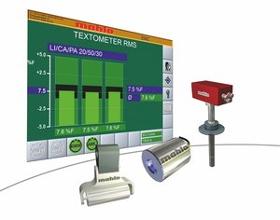

MAHLO GMBH & CO. KG

Germany

Optimizes finishing The Orthopac VMC is a modular process control system for textile refinement. It optimises drying or fixing processes as well as the processes all about the stenter. The system measures, logs and controls critical process parameters over the entire working width like temperature, dwell time, residual moisture, exhaust air moisture, thread density, basis weight and more. This increases quality while saving resources and energy. The modular design of the system allows its flexible adaptation to all applications. Both, standard requirements and highly customized demands are thus met. The system can also be integrated into an Orthopac straightening system. It thereby combines the functionality of a weft straightener with that of a process control system in one compact device.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

DEKORTECH GMBH

Germany

Discover the TURBOTRAN 6.1, the fully automatic heat transfer machine for textile printing with up to 600 pcs./hour. ✔ Efficiency and speed: The machine does it all, from transfer placement to pressing, peeling and giving out the finished textile ✔ Reliable support: Dedicated service team by phone, email or on-site. ✔ Features: Automatic start, a panic button, membrane platens, laser guides, and more This fully automatic heat transfer carousel is the most modern heat press in the market. With 1 operator you can decorate up to 600 t-shirts per hour. Even the application of several transfers at once is possible. The easy to change platens come in any size you need. The TURBOTRAN can be used to apply any kind of transfer but works best with hot peel DTF or screen-printed ones. An outfeed conveyor belt allows an easy integration into your process. Speed up your textile printing business for work wear, sportswear, t-shirts, hoodies, bags and more.

Request for a quote

BRÜCKNER TEXTILE TECHNOLOGIES GMBH & CO. KG

Germany

The stenter is the heart of textile finishing. It develops more and more into a multipurpose line for the production of technical textiles and other webshaped materials. Several thousands of BRÜCKNER stenters are in use all around the globe. Every day they are stentering, drying, heatsetting, functionalizing and coating incountable meters of the most different fabric types. Since many decades BRÜCKNER stenters stand for highest quality and performance and are producing sustainably and energyefficiently. The most important benefits of these stenter frames are highest drying performance and process control matching any type of fabric due to the technically mature and proven splitflow air circulation system, very homogeneous air flow and temperature distribution due to alternately arranged thermo zones, very low specific energy consumption, extremely robust chains, chain rails, pin bar carriers and clips, needing only little maintenance.

Request for a quoteResults for

Textile finishing - Import exportNumber of results

8 ProductsCountries

Company type