- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- lift motor

Results for

Lift motor - Import export

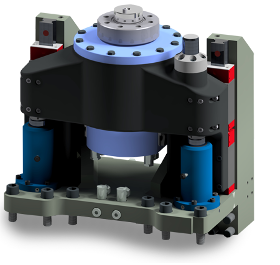

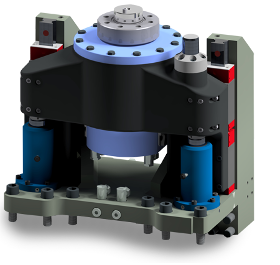

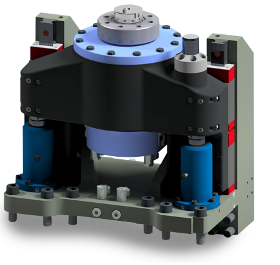

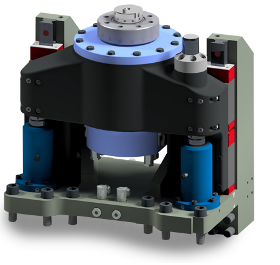

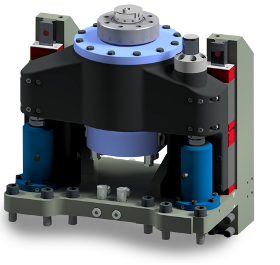

HENSE SYSTEMTECHNIK GMBH & CO. KG

Germany

In principle, in the parallel arrangement, the vertically aligned rotary drive axis (swivel motor) is placed next to the linear drive axis, which is also vertically aligned and preferably consists of two linear cylinders. The swivel motor is inserted and lifted in a motor support mounted separately in linear guides. The pallet holder is mounted directly on the shaft of the swivel motor or in a separate pivot bearing in the motor support. Tilting moments caused by large asymmetrical loading conditions are thus safely absorbed. We offer customized solutions for various applications. Our qualified team will be happy to advise you.

Request for a quote

FOCQUET

Belgium

"Slip ring motors are often used in applications where the maximum transient torque must be greater than a conventional cage induction motor, such as quarries. SLIP RING MOTORS (OUR CODE: MB) - Three-phase wound rotor motors - Standard cast iron housing - Stored in IP55 protection and on request in IP23 - Stored in 230/400V from 22kW to 315kW , 400/690V to 560kW - Operating in 50/60hz - Other special voltages or insulation class H on request - Form B3-B5-V1- B35-V15 - Stored in S1 service or S3 service (6 starts per hour) - On request, we can supply motors for lifting applications with 1 or 2 cylindrical or conical axes - Standard motors equipped with PTC sensors - Equipped with roller bearings for belt drive - Electrolytic starters are stocked to start these motors"

Request for a quote

FERPLAST SNC

Italy

FP SPA 800-DE-1V DOUBLE PANTOGRAPH PLATFORM - ELECTRICAL FEEDING AND ELECTRO-HYDRAULIC LIFTING Double pantograph wheeled lifting platform, completely electric with motorized advancement and lifting. The platform is equipped with: - Driving tiller with feed and lift controls - Two pivoting steering wheels - Two traction wheels - Geared motor for feeding - 24 V electrohydraulic power unit - Chrome cylinder for lifting - 2 long-lasting batteries of 12V / 60Ah each - Single-phase 220 V battery charger supplied

Request for a quote

PRESSTA EISELE GMBH

Germany

Collects swarf and chips in a 1000 litre container can be dumped easily by fork lift. Motor-driven top opens automatically 2 hoods Ø 100mm – without pipe Powered by 4,0 kW, 400 V, 50 Hz motor Performance 4.300 m³/Std. incl. ventilating worm casing above the extractor Large filtre with big surface and external filtre shaker for long durability Steady-state performance or controlled by saw Noise level: 80 db/A Dimension 180 x 320 x 165 cm Weight 380 Kg Serial Paint: RAL 7016 / 9016

Request for a quote

TISCHKÖNIG GMBH

Germany

Melamine table top: - chipboard according to DIN 68765, melamine resin coated on both sides and 2 mm ABS edge - the table top is hygienic, it is not harmful to food, and is simple to clean High-quality frame DT30: - stable steel construction, square columns with 2 motors - 3-stage lifting system (telescopic) - dual motors - height adjustment: 62 - 127 cm (without table top) - max. speed: 35 mm/s without load - collision protection - low noise level: < 45 dB - color: polyester powder-coated - LED display with 4 memory positions - plastic glides for safe standing - level compensation up to 10 mm Selection options: - table top color - table top thickness - dimension - frame color

Request for a quote

HANSA-HOLZ-KONTOR HORST RÜCKLE GMBH & CO. KG

Germany

Frame system with 3 built-in motors tasked to adjust the head, back and foot regions to any position required within the limits. Lifting built-in motor, height adjustable by 35 cm offering the benefits of a slatted frame for nursing beds. Quiet technology. Film coated slatted frame in multi-layer birch, with 28 slats. Mounted in flexible DUO caps covering the side rails. Individually adjustable level of firmness in the centre zone. Shoulder comfort zone. Load distributing centre belt.

Request for a quote

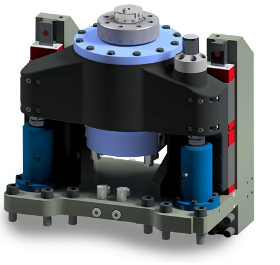

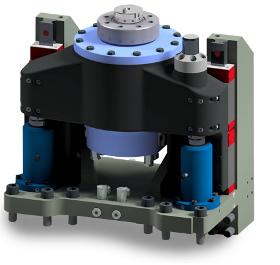

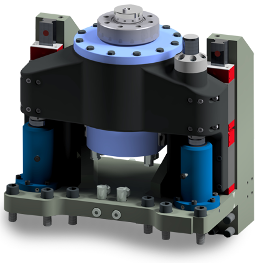

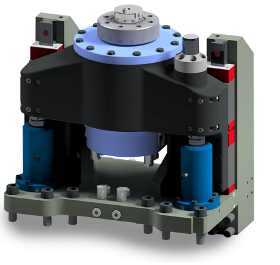

HENSE SYSTEMTECHNIK GMBH & CO. KG

Germany

In principle, in the parallel arrangement, the vertically aligned rotary drive axis (swivel motor) is placed next to the linear drive axis, which is also vertically aligned and preferably consists of two linear cylinders. The swivel motor is inserted and lifted in a motor support mounted separately in linear guides. The pallet holder is mounted directly on the shaft of the swivel motor or in a separate pivot bearing in the motor support. Tilting moments caused by large asymmetrical loading conditions are thus safely absorbed. We offer customized solutions for various applications. Our qualified team will be happy to advise you.

Request for a quote

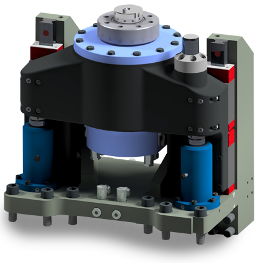

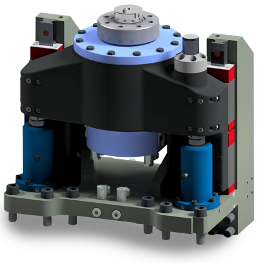

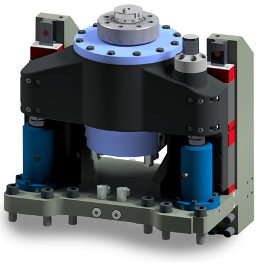

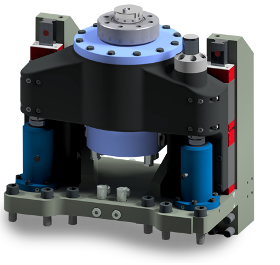

HENSE SYSTEMTECHNIK GMBH & CO. KG

Germany

In principle, in the parallel arrangement, the vertically aligned rotary drive axis (swivel motor) is placed next to the linear drive axis, which is also vertically aligned and preferably consists of two linear cylinders. The swivel motor is inserted and lifted in a motor support mounted separately in linear guides. The pallet holder is mounted directly on the shaft of the swivel motor or in a separate pivot bearing in the motor support. Tilting moments caused by large asymmetrical loading conditions are thus safely absorbed. We offer customized solutions for various applications. Our qualified team will be happy to advise you.

Request for a quote

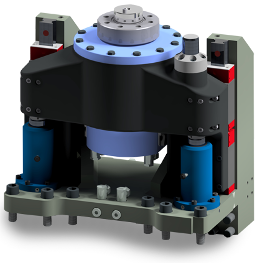

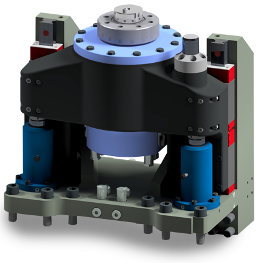

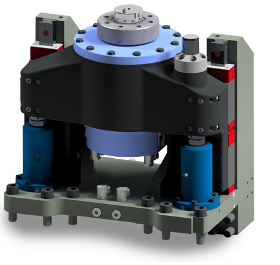

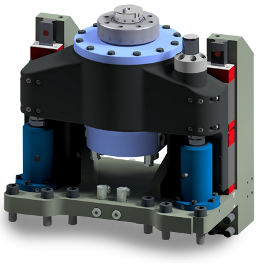

HENSE SYSTEMTECHNIK GMBH & CO. KG

Germany

In principle, in the parallel arrangement, the vertically aligned rotary drive axis (swivel motor) is placed next to the linear drive axis, which is also vertically aligned and preferably consists of two linear cylinders. The swivel motor is inserted and lifted in a motor support mounted separately in linear guides. The pallet holder is mounted directly on the shaft of the swivel motor or in a separate pivot bearing in the motor support. Tilting moments caused by large asymmetrical loading conditions are thus safely absorbed. We offer customized solutions for various applications. Our qualified team will be happy to advise you.

Request for a quote

HENSE SYSTEMTECHNIK GMBH & CO. KG

Germany

In principle, in the parallel arrangement, the vertically aligned rotary drive axis (swivel motor) is placed next to the linear drive axis, which is also vertically aligned and preferably consists of two linear cylinders. The swivel motor is inserted and lifted in a motor support mounted separately in linear guides. The pallet holder is mounted directly on the shaft of the swivel motor or in a separate pivot bearing in the motor support. Tilting moments caused by large asymmetrical loading conditions are thus safely absorbed. We offer customized solutions for various applications. Our qualified team will be happy to advise you.

Request for a quote

HENSE SYSTEMTECHNIK GMBH & CO. KG

Germany

In principle, in the parallel arrangement, the vertically aligned rotary drive axis (swivel motor) is placed next to the linear drive axis, which is also vertically aligned and preferably consists of two linear cylinders. The swivel motor is inserted and lifted in a motor support mounted separately in linear guides. The pallet holder is mounted directly on the shaft of the swivel motor or in a separate pivot bearing in the motor support. Tilting moments caused by large asymmetrical loading conditions are thus safely absorbed. We offer customized solutions for various applications. Our qualified team will be happy to advise you.

Request for a quote

HENSE SYSTEMTECHNIK GMBH & CO. KG

Germany

In principle, in the parallel arrangement, the vertically aligned rotary drive axis (swivel motor) is placed next to the linear drive axis, which is also vertically aligned and preferably consists of two linear cylinders. The swivel motor is inserted and lifted in a motor support mounted separately in linear guides. The pallet holder is mounted directly on the shaft of the swivel motor or in a separate pivot bearing in the motor support. Tilting moments caused by large asymmetrical loading conditions are thus safely absorbed. We offer customized solutions for various applications. Our qualified team will be happy to advise you.

Request for a quote

HENSE SYSTEMTECHNIK GMBH & CO. KG

Germany

In principle, in the parallel arrangement, the vertically aligned rotary drive axis (swivel motor) is placed next to the linear drive axis, which is also vertically aligned and preferably consists of two linear cylinders. The swivel motor is inserted and lifted in a motor support mounted separately in linear guides. The pallet holder is mounted directly on the shaft of the swivel motor or in a separate pivot bearing in the motor support. Tilting moments caused by large asymmetrical loading conditions are thus safely absorbed. We offer customized solutions for various applications. Our qualified team will be happy to advise you.

Request for a quote

HENSE SYSTEMTECHNIK GMBH & CO. KG

Germany

In principle, in the parallel arrangement, the vertically aligned rotary drive axis (swivel motor) is placed next to the linear drive axis, which is also vertically aligned and preferably consists of two linear cylinders. The swivel motor is inserted and lifted in a motor support mounted separately in linear guides. The pallet holder is mounted directly on the shaft of the swivel motor or in a separate pivot bearing in the motor support. Tilting moments caused by large asymmetrical loading conditions are thus safely absorbed. We offer customized solutions for various applications. Our qualified team will be happy to advise you.

Request for a quote

HENSE SYSTEMTECHNIK GMBH & CO. KG

Germany

In principle, in the parallel arrangement, the vertically aligned rotary drive axis (swivel motor) is placed next to the linear drive axis, which is also vertically aligned and preferably consists of two linear cylinders. The swivel motor is inserted and lifted in a motor support mounted separately in linear guides. The pallet holder is mounted directly on the shaft of the swivel motor or in a separate pivot bearing in the motor support. Tilting moments caused by large asymmetrical loading conditions are thus safely absorbed. We offer customized solutions for various applications. Our qualified team will be happy to advise you.

Request for a quote

HENSE SYSTEMTECHNIK GMBH & CO. KG

Germany

In principle, in the parallel arrangement, the vertically aligned rotary drive axis (swivel motor) is placed next to the linear drive axis, which is also vertically aligned and preferably consists of two linear cylinders. The swivel motor is inserted and lifted in a motor support mounted separately in linear guides. The pallet holder is mounted directly on the shaft of the swivel motor or in a separate pivot bearing in the motor support. Tilting moments caused by large asymmetrical loading conditions are thus safely absorbed. We offer customized solutions for various applications. Our qualified team will be happy to advise you.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

HENSE SYSTEMTECHNIK GMBH & CO. KG

Germany

In principle, in the parallel arrangement, the vertically aligned rotary drive axis (swivel motor) is placed next to the linear drive axis, which is also vertically aligned and preferably consists of two linear cylinders. The swivel motor is inserted and lifted in a motor support mounted separately in linear guides. The pallet holder is mounted directly on the shaft of the swivel motor or in a separate pivot bearing in the motor support. Tilting moments caused by large asymmetrical loading conditions are thus safely absorbed. We offer customized solutions for various applications. Our qualified team will be happy to advise you.

Request for a quote

HENSE SYSTEMTECHNIK GMBH & CO. KG

Germany

In principle, in the parallel arrangement, the vertically aligned rotary drive axis (swivel motor) is placed next to the linear drive axis, which is also vertically aligned and preferably consists of two linear cylinders. The swivel motor is inserted and lifted in a motor support mounted separately in linear guides. The pallet holder is mounted directly on the shaft of the swivel motor or in a separate pivot bearing in the motor support. Tilting moments caused by large asymmetrical loading conditions are thus safely absorbed. We offer customized solutions for various applications. Our qualified team will be happy to advise you.

Request for a quote

HENSE SYSTEMTECHNIK GMBH & CO. KG

Germany

In principle, in the parallel arrangement, the vertically aligned rotary drive axis (swivel motor) is placed next to the linear drive axis, which is also vertically aligned and preferably consists of two linear cylinders. The swivel motor is inserted and lifted in a motor support mounted separately in linear guides. The pallet holder is mounted directly on the shaft of the swivel motor or in a separate pivot bearing in the motor support. Tilting moments caused by large asymmetrical loading conditions are thus safely absorbed. We offer customized solutions for various applications. Our qualified team will be happy to advise you.

Request for a quote

HENSE SYSTEMTECHNIK GMBH & CO. KG

Germany

In principle, in the parallel arrangement, the vertically aligned rotary drive axis (swivel motor) is placed next to the linear drive axis, which is also vertically aligned and preferably consists of two linear cylinders. The swivel motor is inserted and lifted in a motor support mounted separately in linear guides. The pallet holder is mounted directly on the shaft of the swivel motor or in a separate pivot bearing in the motor support. Tilting moments caused by large asymmetrical loading conditions are thus safely absorbed. We offer customized solutions for various applications. Our qualified team will be happy to advise you.

Request for a quote

HENSE SYSTEMTECHNIK GMBH & CO. KG

Germany

In principle, in the parallel arrangement, the vertically aligned rotary drive axis (swivel motor) is placed next to the linear drive axis, which is also vertically aligned and preferably consists of two linear cylinders. The swivel motor is inserted and lifted in a motor support mounted separately in linear guides. The pallet holder is mounted directly on the shaft of the swivel motor or in a separate pivot bearing in the motor support. Tilting moments caused by large asymmetrical loading conditions are thus safely absorbed. We offer customized solutions for various applications. Our qualified team will be happy to advise you.

Request for a quote

HENSE SYSTEMTECHNIK GMBH & CO. KG

Germany

In principle, in the parallel arrangement, the vertically aligned rotary drive axis (swivel motor) is placed next to the linear drive axis, which is also vertically aligned and preferably consists of two linear cylinders. The swivel motor is inserted and lifted in a motor support mounted separately in linear guides. The pallet holder is mounted directly on the shaft of the swivel motor or in a separate pivot bearing in the motor support. Tilting moments caused by large asymmetrical loading conditions are thus safely absorbed. We offer customized solutions for various applications. Our qualified team will be happy to advise you.

Request for a quote

AVM AUTOMATION

France

Lifting table for electric motor Fixing with its reinforced end for vertical using Drived by ballscrew or leadscrew Guided by 2 rods on ball bushings (or plain bearings in leadscrew version) Motor adaptation for lifting table These lifting tables are delivered without motor, but the adaptation of your motor can be done by us. Some adaptations are standard, especially for standard motors (NEMA17 or NEMA23), if the dimensions of your motor are not listed, contact us to check the feasibility of your motor adaptation from our rough parts. Presentation of the lifting tables to be motorized The trapezoidal screw version is irreversible and the axial precision is <0.15 mm (in practice 0,02 to 0,10 mm). The ballscrew version is reversible and the axial accuracy is <0.07 mm. The maxi stroke is 300 mm, and any intermediate stroke can be produced. Assembly of tables in XZ, YZ or XYZ systems For a crossed table XZ

Request for a quote

BERTAZZON 3B SRL

Italy

The Swing Carousel consists of a rotating structure rising along a central column and supporting two rows of swinging chairs for accommodation of 1 passenger each. Double seats is also possible, to accommodate one adult and one child. All decorative panels are made out of fibreglass/alluminium with galvanized-steel frame. All decoration are hand made and all painting one by one hand-brush executed. Lighting is permanently mounted on decorative elements. The swinging chairs and their supporting chains are made by stainless steel and fibreglass shells. The covering roof consist of decorative fiberglass globe. The rotation is made by one self-braking AC motors and lifting by two hydraulic pistons.

Request for a quote

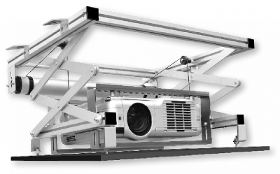

MULTIVISION SCREENS SPRL

Belgium

The PROJECTOR LIFT MVS 500 is equipped with heavy-duty but silent motor which assures a fast and stable up-down movement of the projector. Furthermore, the motor is provided with an RF remote control and offers the possibility to set three motor limit stops: an upper stop limit, an intermediate one and a down one. The intermediate stop can be set at the desired height for projection mode, whereas the down one can be adjusted up to 500 cm. stroke to be used as service mode position. Also a safety device is built-in in order to offer maximum security in case of any failure of the mechanism. The projector anchoring frame movement is controlled by two strong steel cables that are certified for a maximum load of 350 kg. each.

Request for a quote

MULTIVISION SCREENS SPRL

Belgium

The PROJECTOR LIFT MVS 40-25 is studied in order to support large and heavy Professional and Home Cinema video projectors up to 25 Kg. of weight. The lift has been developed to be installed inside a very narrow false ceilings of only 14 cm. granting the best aesthetic and practical solution in hiding the projector, lift and cables. The MVS 40-25 is supplied with a powered and extremely silent motor that allows a descent from a minimum of 14 cm to a maximum of 54 cm. Moreover it is supplied with extendable side brackets in order to allow an easy fixing of the panel of your false ceiling by adjustable threaded bars. The lift MVS 40-25 is equipped with two safety screws which prevents the lift to extent further to the preset end stop. *ceiling cover plate not included

Request for a quote

MULTIVISION SCREENS SPRL

Belgium

The heavy PROJECTOR LIFT SERIES MVS 300 is a very strong and reliable new range of lifts specifically developed for large venue applications where large projectors need to be moved. These lifts are equipped with heavy-duty but silent motor which assures a fast and stable up-down movement of the projector. Also a SAFETY DEVICE is built-in in order to offer maximum security in case of any failure of the mechanism. The projector anchoring frame movement is controlled by two strong steel cables that are certified for a maximum load of 350 kg. each. A unique and professional cable management system is supplied integrated in the product. This allows to connect safely and tidily the projector with the power and signal cables.

Request for a quote

MULTIVISION SCREENS SPRL

Belgium

The PROJECTOR LIFT MVS 30-15 is a versatile very compact projector lift that enables the installation of projectors in environments where particular aesthetical solutions are required. The product has been developed to be installed inside a false ceiling where very few space is available. You need inside the false ceiling only 13 cm. of minimum height to install lift and projector. The MVS 30-15 is supplied with an extremely silent motor that allows a descent of maximum 30 cm and can carry up to 15kg. The lift is supplied with two safety screws. * ceiling cover plate is NOT included

Request for a quoteResults for

Lift motor - Import exportNumber of results

53 ProductsCountries

Company type

Category

- Electric motors and parts (19)

- Lifting equipment (4)

- Hoists and winches (3)

- Buckets and grabs, crane (2)

- Lifting - vehicles (2)

- Railway stock and equipment (2)

- Batteries (1)

- Bearings, ball (1)

- Beds, bedsteads and mattresses (1)

- Construction cranes (1)

- Electric motors - dC (1)

- Hoists and elevators, construction (1)

- Hospital beds (1)

- Lifts and escalators (1)

- Packing and packaging - machinery and equipment (1)

- Swings (1)

- Tables and chairs (1)

- Trailers, industrial (1)

- Trolleys and trucks (1)