- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- textile finishing

Results for

Textile finishing - Import export

BESER KIMYA SAN. VE TIC. LTD.STI.

Turkey

Product prepared with 8 – 10 % emulsifier and mineral base oil gives milky oil in water emulsions for textile fiber processing. Used for textile oil preparation for spinning, synthetic and wool fiber blending, cone transferring, kamgarn and streighgarn spinning operations Nonyl Phenol free nonionic type emulsifier package gives highly hard water resistant stable emulsions up to 100 DH Emulsifies easily and gives high degree of lubrication and washability. Eliminates static electric deposition during spinning

Request for a quote

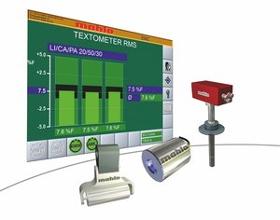

MAHLO GMBH & CO. KG

Germany

Compressed air blade To monitor the progress of certain processes, there is no alternative but to take frequent samples at the machine itself. This is normally possible only while the product is either moving slowly or stopped, and often results in complicated work-arounds to enable continual production (continuously running winders, etc.). The Samplecut FSC is the solution to the problem. The tried and tested sample cutter Samplecut FSC takes samples from fast running product.

Request for a quote

MAHLO GMBH & CO. KG

Germany

Keeps web safely on track Drifting of the product web lateral to the running direction of product is unavoidable in some stages of textile finishing. The Ceremat system brings the product back on the right path. Applicationspecific variants are available.

Request for a quote

MAHLO GMBH & CO. KG

Germany

Control room application mPilot is a control room application for Mahlo equipment. The software allows the user to configure up to ten Mahlo devices with one control centre. Individually selected data of several devices are clearly arranged. The innovative control tool supports production and shift managers in handling their daily business as efficiently as possible. Key elements Display of running processes of up to ten Mahlo machines Job control (configure jobs and recipes) Configuration of product lines and machines Alarm management (current and historical warnings) Various communication protocols (OPC UA, OPC DA, Modbus TCP, Profibus, Profinet, Ethernet/IP) Start of predefined jobs (only with mCockpit)

Request for a quote

MAHLO GMBH & CO. KG

Germany

Optimizes drying The Ecopac EMC uses the state of the art microprocessor technology to ensure product quality and optimise the energy balance for drying processes. The modular system for monitoring and controlling residual moisture, product temperature, dwell time and exhaust air humidity can be flexibly adapted to current production. Up to three of the same or different modules may be used as needed. This increases quality while saving resources and energy. The modular design of the system allows its flexible adaptation to all applications. Both, standard requirements and highly customized demands are thus met.

Request for a quote

MAHLO GMBH & CO. KG

Germany

Optimizes finishing The Orthopac VMC is a modular process control system for textile refinement. It optimises drying or fixing processes as well as the processes all about the stenter. The system measures, logs and controls critical process parameters over the entire working width like temperature, dwell time, residual moisture, exhaust air moisture, thread density, basis weight and more. This increases quality while saving resources and energy. The modular design of the system allows its flexible adaptation to all applications. Both, standard requirements and highly customized demands are thus met. The system can also be integrated into an Orthopac straightening system. It thereby combines the functionality of a weft straightener with that of a process control system in one compact device.

Request for a quote

ONURAY

Turkey

It is manufactured in different working widths according to customer requests. It can be produced with two or three cylinders upon request.

Request for a quote

ONURAY

Turkey

Printing / Dye Kitchens Specifications: It consists of a pat preparation mixer, stock tanks, paint mixers and vacuum filter in the capacity of customer requests. It provides low energy consumption and fast preparation. The machines are completely made of AISI304 quality Cr-Ni material. It can be produced in manual or automatic operation feature depending on demand.

Request for a quote

ONURAY

Turkey

Wet Fabric Opening Machine Technical Specifications All parts completely AISI304 stainless steel. Preparation for quality product with pre-pressing and foulard system. Height adjustable tower. High working speed (Max.100 m / min) Suitable for all kinds of fabrics. Special design with cutting apparatus for tubular knitted fabrics. Specially designed opening head. Fully automatic operation feature. Production for different fabric widths. (180 cm, 220 cm, 240 cm, 320 cm, 360 cm)

Request for a quote

DORU MAKINA VE DIS TICARET

Turkey

BALE PRESS MD 25 Bale press Designed for operation in tight spaces and low ceiling heights. It offers a highly efficient printing usage area through internal cross cylinders. Chopper: It is specially designed to perform deformation on products with the help of special design knives. J CONVEYOR AND LOADING CONVEYOR It is overflowing in such a way that the products work highly efficiently in pallets for proper transportation between operations. Side enclosures equipped with all safety measures to ensure safe and healthy transportation are specially designed for the flow of products. MD 25 Bale press Bale Size (mm) : 1200 x 800 x 800 Machine Size (mm) : 1750 x 1255 x 2000 Number of serit channels : 4 Bale striping : String Bale Unloading : Automatic Hydraulic Unit Engine (kW) : 4 Speed (seconds) : 38 Press Power : 25 t Stroke (mm) : 950

Request for a quote

DORU MAKINA VE DIS TICARET

Turkey

arn Fixing Machine - Steam Master AISI 304 quality Cr-Ni body. High efficiency vacuum pump. Hydraulic and safe cover system. Indirect heating system. (Electric or Steam) Different loading apparatus (Caglik, Pan or Pallet) Optional automatic loading systems. Machines with varying capacities according to customer demands. (150-1500 kg / charge) Homogeneous heat and moisture distribution in all yarns. Fully automated control program that provides repeatable fixation requirements. -0.8 – 2 Bar Working Pressure. Maximum operating temperature of 135 °C. (142 °C with special production) Maximum security. (electronic, electro-mechanical and mechanical) Monitoring and reporting with central network networks.

Request for a quote

NANOMAGIC

Ireland

MAGIC TEXTILE COAT is an innovative water repellent nano-coating protects almost any type of textile from water, dirt, contamination and stains – whilst remaining totally invisible! It will not affect the appearance, its ability to breath, its color or handle and is easy to maintain. Nano coatings are exceedingly water - resistant on outdoor materials; keeping them drier longer. Oil, coffee and other frequent stains belong to the past, if the material is treated with our protective products. Rain, mud, ketchup, syrup and other liquids don't stand a chance! Because Magic Textile Coat is super-hydrophobic, water is actively repelled from a treated surface. Water-based liquids roll right off a surface on contact and leave materials clean and dry or easy to clean.

Request for a quote

MICRON AMERICA

Turkey

Eyelet Attaching Machine is one of the most versatile fastener attaching machines available today. With interchangeable dies, you can use the MC-20 to attach just about any size and style of Eyelets available. You can also use the Micron MC-20 Double Cylinder Eyelet Press to attach Spring Snaps, Ring Snaps, Jean Rivets and Jean Buttons of various sizes and styles.

Request for a quote

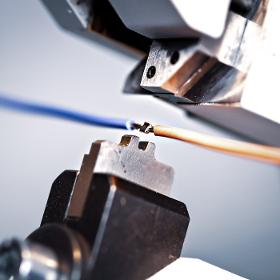

EMBRO GMBH

Germany

The semi-finished products manufactured by Embro GmbH are optionally available with an electrical connection. In addition to the many possibilities of placing different elements on carrier materials with special embroidery processes, Embro offers splicing or soldering techniques for perfect and cost-effective connections. The parts are crimped or soldered together as standard. The introduction of thermal switches, NTC or other cable solutions is also no problem. Special connector solutions can also be implemented. This means that the textile semi-finished products are plug & play ready upon delivery. #service #contacting #b2b

Request for a quote

DEKORTECH GMBH

Germany

Discover the TURBOTRAN 6.1, the fully automatic heat transfer machine for textile printing with up to 600 pcs./hour. ✔ Efficiency and speed: The machine does it all, from transfer placement to pressing, peeling and giving out the finished textile ✔ Reliable support: Dedicated service team by phone, email or on-site. ✔ Features: Automatic start, a panic button, membrane platens, laser guides, and more This fully automatic heat transfer carousel is the most modern heat press in the market. With 1 operator you can decorate up to 600 t-shirts per hour. Even the application of several transfers at once is possible. The easy to change platens come in any size you need. The TURBOTRAN can be used to apply any kind of transfer but works best with hot peel DTF or screen-printed ones. An outfeed conveyor belt allows an easy integration into your process. Speed up your textile printing business for work wear, sportswear, t-shirts, hoodies, bags and more.

Request for a quote

FERPLAST SNC

Italy

Electric sewing machine Mod. FPMP 82 (220 V and 12 V ) for bags particularly robust, vibration-free, usable in agricultural industries, chemical, food, packaging, textiles, for use in finishing. Suitable for sealing bags of a different type of paper, jute, fabric and plasticized, etc. such as bags of food or chemicals. The FPMP 82 can be used for the sewing of the collection nets of olives or antihail. The operation with reciprocating motion with "wear" arrangement allows a very efficient grip even on medium to high thicknesses. The machine works with standard 220 volt electric cable. It's also available in 12V that can be equipped with external battery and backpack. For uses other than those listed please send us a test sample of your product.

Request for a quote

LATRO KIMYA DIS TIC A.S.

Turkey

Texhydro® FLASH is a next generation textile enhancer which helps providing softness and slickness to fabrics and garments. Especially recommend, for its high affinity, for synthetic and blend fabrics.It provides no yellowing effect, extreme shear stability, pH- temperature stability and electrolyte stability. Texhydro® FLASH is water dispersible and it is effective when used three to four times lower compared to amino silicone fluids. Proovides natural softness to sentetics and the blends Does not change the fastness value at 160 degrees High durability and resistance No yellowing Extreme stability under finishing conditions Applicable in padding and exhaustion process Self-dispersible Can be blended directly into the textile finishing bath Easy to handle Texhydro® FLASH can be considered to be utilized in textile finishing in all synthetics, synthetic/cotton blends, wool and polyester fleece. It can also be used on cotton fabrics.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

LOUISON INDUSTRIES

France

- What type of market? - What choice of raw material? - What technical constraints? - Dimensions: Width up to 1800 mm - Regulations: OEKO-TEX; REACH standard - Finishing : Polyvinyl chloride, polypropylene, PU polyurethane UV resistance, waterproofing, anti-virus and anti-bacteria, anti-abrasive, thermal insulation, fire resistance, etc,

Request for a quote

PIANEX

Poland

Working width 3300mm 150mm stroke Beats per minute 800 Uiglenie 10 000igiel/m

Request for a quote

KUTLUCAN TEKSTIL

Turkey

Our yarns are used in weaving, knitting and knitwear as well as women's / men's clothing, military, safety and outdoor clothing, as well as lace, socks, seamless clothing, sportswear and technical textiles. Polyamide (nylon) yarns are also used in fabric production together with natural or other synthetic yarns.

Request for a quote

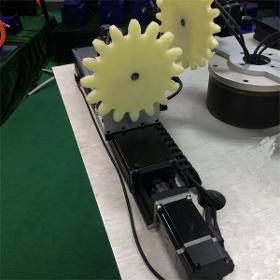

PJM MECHANICAL CO.,LTD

China

CNC motor,Semi conduct motor,Military motor,Aerospace motor,Industrail automation motor.Application:Advertisement and engraving,wood engraving,digital control machine-tool,line cutter,ultrasonic welder,water cutter,optical fiber glass stretcher,gantry crane system,food processing,package printing,paper board transport,textile print and dyeing,artificial chew simulator,blood tester,CAT scanner,DNA tester,pacemeter,robot

Request for a quote

ONURAY

Turkey

Yarn Fixing and Conditioning Machine Technical Specifications: AISI 304 quality Cr-Ni body. High efficiency vacuum pump. Hydraulic and safe cover system. Indirect heating system. (By Electricity or Steam) Different loading apparatus (Creel, Pan or Pallet) Optional automatic loading systems. Machines with variable capacities according to customer demands. (150-2500 kg / charge) Homogeneous heat and moisture distribution in all yarns. Fully automatic control program providing reproducible fixing conditions. -0,8 - 2 Bar Working Pressure. Maximum 135 ° C operating temperature. (142 ° C with special production) Maximum safety. (electronic, electro-mechanical and mechanical) Monitoring and reporting with central networks.

Request for a quote

BRÜCKNER TEXTILE TECHNOLOGIES GMBH & CO. KG

Germany

The stenter is the heart of textile finishing. It develops more and more into a multipurpose line for the production of technical textiles and other webshaped materials. Several thousands of BRÜCKNER stenters are in use all around the globe. Every day they are stentering, drying, heatsetting, functionalizing and coating incountable meters of the most different fabric types. Since many decades BRÜCKNER stenters stand for highest quality and performance and are producing sustainably and energyefficiently. The most important benefits of these stenter frames are highest drying performance and process control matching any type of fabric due to the technically mature and proven splitflow air circulation system, very homogeneous air flow and temperature distribution due to alternately arranged thermo zones, very low specific energy consumption, extremely robust chains, chain rails, pin bar carriers and clips, needing only little maintenance.

Request for a quote

DINAPAMA MANUFACTURING & SUPPLIES

Namibia

Our main focus is on tshirts and apparel, from the simplest single color prints to the most complex eye-popping multicolor reproductions. Let us wield our screen printing magic in your service!

Request for a quote

DINAPAMA MANUFACTURING & SUPPLIES

Namibia

Our heat press machines are engineered to imprint a design or graphic on a substrate, such as a t-shirt, with the application of heat and pressure for a preset period of time.

Request for a quote

OFFICINA MASTER S.P.A

Italy

Vaporizing machine Saturno – Designed to relax the textile fibers and allow dimensional stability. The fabric in entrance, as plaite, big or small roll, is overfed and spread on a perforated conveyor belt that carries it through the different working fields. The first two sections of the treatment system are constituted by high temperature vaporizing tunnels, realized in stainless steel with anti-condensation units. Between the two sections there is a device that makes the belt vibrate to facilitate the relaxation and shrinkage of the fibers. At the output of the last steaming tunnel, an adjustable forced hot air drying group is installed. In the final part of the machine there is a double cooling field blocking the movement of the fibers (thermic shock). Both the drying field and the cooling one are above the conveyor belt in order to avoid a direct contact between the air flows and the right side of the fabric.

Request for a quote

OFFICINA MASTER S.P.A

Italy

Olimpia Equalizing - It has the dual advantage of occupying less room and to be able to view the fabric for a length of about 4 m that no other inspection table can do . Used to give volume to stressed fibers. To equalize the fabric weight, to roll in a perfect way.

Request for a quote

OFFICINA MASTER S.P.A

Italy

Non-stop equalizing used right after ramose, decatizing or other textile finishing machines for perfectly rolling with no tension. All machines has 2 processing zones: one divergent (conical =1mt) where fabric is raised to the desired width; the other parallel=0.5mt, where fabric is stabilized and rolled. Optional can be added 2 vaporizing trays to eliminate creases.

Request for a quoteResults for

Textile finishing - Import exportNumber of results

29 ProductsCompany type

Category

- Textile finishing (14)

- Textiles - finishing, printing and dyeing machinery (13)

- Textile finishing - machinery and equipment (12)

- Textiles - Machines & Equipment (3)

- Sewing machines and accessories - industrial (1)

- Shampoos (1)

- Silk-screen printing (1)

- Software (1)

- Technical textiles (1)

- Technical textiles for industrial applications (1)

- Textile cutting machinery (1)

- Textile dyeing (1)