- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- metal grinding

Results for

Metal grinding - Import export

ROKVELAS, UAB

Lithuania

Flat grinding up to 200x500 mm.

Request for a quote

MARXAM PROJECT

Poland

The grinding services are a surface finishing process that includes every detail that requires the removal of machining allowance and obtaining large classes of surface roughness. For technological reasons and the number of requirements as to the further condition of the surface of the elements, we adjust the metal grinding process to individual customer requirements. Metal grinding is a finishing treatment involving the treatment of surfaces of various shapes with abrasive tools. Grinding allows you to remove burrs (deburring) and roughness, as well as machining allowance. This surface finishing method allows to obtain a surface with low roughness and desired shapes and dimensions with quite high accuracy. Surface grinding is one of the most common methods of surface treatment, for a wide variety of metals, including grinding steel, metal grinding bits, grinding welds, aluminum grinding and many others.

Request for a quote

FRIEDRICH AUGUST PICARD GMBH & CO. KG

Germany

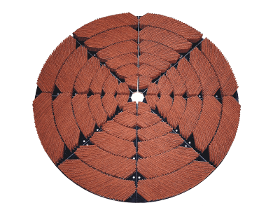

The further development of our deburring grinding plates are our patented deburring segments FAPI-FLEX-SAT (patent no. DE20304860 U1). These advanced deburring segments were developed in collaboration with the company Timesavers from the Netherlands. Fast, safe and clean deburring or edge rounding of sheet metal parts is no longer a problem when using these tools. Deburring grinding segments can also be individually adapted depending on the application. We would be pleased to advise you on which deburring discs can be used in your processing, in order to achieve top process results. Please note, other trim types are available upon request!

Request for a quote

FRIEDRICH AUGUST PICARD GMBH & CO. KG

Germany

When processing sheet metal parts by punching, lasering, plasma cutting, flame cutting, etc., a burr is always created. We have met the challenge of deburring or rounding these “sharp” edges of the workpieces in companies by developing our deburring grinding wheels and deburring rollers. By using these highly flexible tools, both on hand machines and on automatic machines, sheet metal parts can be optimally rounded or deburred. We have the right dimensions for your deburring machine! We would be pleased to advise you on which deburring rollers can be used in your processing, in order to achieve top process results.

Request for a quote

FRIEDRICH AUGUST PICARD GMBH & CO. KG

Germany

The deburring grinding discs from the FAPI-TRIM series are the ideal tool for deburring on automatic deburring machines (e.g. Weber deburring machines) and are particularly suitable for processing larger series. We would be pleased to advise you on which deburring discs can be used in your processing, in order to achieve top process results.

Request for a quote

FRIEDRICH AUGUST PICARD GMBH & CO. KG

Germany

The deburring discs of the FAPI-M14 125 series are the ideal tool of hand operated deburring. The integrated M14 thread can be adjusted to regulated angle grinders and are especially fit for smaller and medium series, in which the purchase of an automatic deburring machine is not worthwhile. We would be pleased to advise you on which deburring discs can be used in your processing, in order to attain top process results.

Request for a quote

FRIEDRICH AUGUST PICARD GMBH & CO. KG

Germany

The deburring discs of the FAPI-FIT150 series are the ideal tool for deburring on automatic deburring machines and are particularly suitable for machining larger series. Various deburring machines are equipped with right- and left-rotating deburring discs. For this purpose we offer you our FAPI-QUICK-FIT ADAPTER! The combination of the quick-clamping system and our FAPI-QUICK-FIT ADAPTER also enables simple mounting and positioning of the deburring discs FAPI-FIT150 on the deburring machine. We will be pleased to advise you which fill variant is best suited for your application.

Request for a quote

FRIEDRICH AUGUST PICARD GMBH & CO. KG

Germany

The deburring grinding discs of the FAPI-250 series are the ideal tool for deburring on automatic deburring machines (e.g. Loewer DiscMaster 4TD) and are particularly suitable for processing larger series. We would be pleased to advise you on which deburring discs can be used in your processing, in order to achieve top process results.

Request for a quote

FRIEDRICH AUGUST PICARD GMBH & CO. KG

Germany

The deburring grinding discs of the FAPI-150 series are the ideal tool for deburring on automatic and manual deburring machines (e.g. our deburring machine FAPI-STARGRINDER) and are particularly suitable for processing larger series. The 25 mm bore and 4 driver holes enable easy assembly and positioning of the FAPI-150 deburring grinding disk on the deburring machine. We would be pleased to advise you on which deburring discs can be used in your processing, in order to achieve top process results.

Request for a quote

FRIEDRICH AUGUST PICARD GMBH & CO. KG

Germany

The deburring discs of the FAPI-125 series are the ideal tool for deburring on automatic, stationary deburring machines and are particularly suitable for processing larger series. The shank allows easy mounting and positioning of the deburring discs FAPI-125 on the deburring machine. We will be pleased to advise you which fill variant is best suited for your application. Product features Ultra-fast setup times The shank allows easy mounting and positioning of the deburring discs FAPI-125 on the deburring machine. The selection of different densities, fill lengths, abrasive cloth and abrasive fleece types can have a decisive influence on the deburring process. The optimum design of the deburring discs FAPI-125 can be determined from the process parameters dry or wet grinding, the material to be processed, the material thickness and the desired surface quality or roughness depth. We will be happy to advise you in order to find a suitable deburring disk for you.

Request for a quote

FRIEDRICH AUGUST PICARD GMBH & CO. KG

Germany

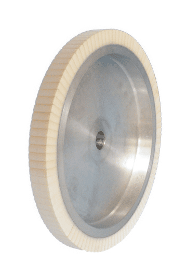

As the name indicates, the aluminium hub of the contact wheel FAPI-VUS DENSE is coated with dense adjoining lamellae of foamed up Vulkollan®. The length of the lamellae of foamed up Vulkollan® can be varied depending on the application (standard: 20 and 35 mm). The lamellae of foamed up Vulkollan® provide the contact wheel with a “running cushion” with which a fine finish is possible especially when working on (strongly) cambered and profiled pieces. The coating adapts to every workpiece to be found. In addition, the contact wheel FAPI-VUS dense contributes in large measure to abrasive belt cooling because the spaces between the lamellae dissipate the heat. Benefits of contact wheels with lamellae of foamed up Vulkollan® : Highly elastic (adaptable) Wear-resistance Oil-resistance Grease-resistance We will be happy to advise you in order to find a suitable contact wheel for you.

Request for a quote

FRIEDRICH AUGUST PICARD GMBH & CO. KG

Germany

We offer a wide variety of grades with various dimensions and grain sizes of abrasive belts that are perfectly suited to your application and processes. We will be happy to advise you to find the right sanding belts for you.

Request for a quote

FRIEDRICH AUGUST PICARD GMBH & CO. KG

Germany

Whether aluminum, steel or stainless steel… We have the right BLOCKbuster for your deburring process! Our sanding block FAPI-EVO offers greater efficiency when rounding edges thanks to the TRIPLE FLEX trim variant. A selection of trim types that are specifically tailored to the material to be processed offers you the opportunity to select the sanding block individually for your process. Thanks to the innovative tool attachment, the sanding blocks are secured against twisting/slipping on the power belt. We would be happy to advise you on which type of trim is best suited to your application.

Request for a quote

FRIEDRICH AUGUST PICARD GMBH & CO. KG

Germany

The FAPI-ATTACK sanding disc is ideal for extremely aggressive sanding work and is primarily used for aggressive sanding on the surface as well as on the edge. We would be pleased to advise you on which grinding disk can be used in your processing, in order to achieve top process results. Please note, other trim types are available upon request!

Request for a quote

IMM MASCHINENBAU GMBH

Germany

Heavy duty belt sanding and polishing jack for industrial applications. Compact double ended design. Floor standing pedestal. Rapid belt tensioning and tracking. Also for alumimun polishing.

Request for a quote

TYROLIT - SCHLEIFMITTELWERKE SWAROVSKI AG & CO K.G

Austria

Metal-bonded grinding tools for flute grinding With the STARTEC XP-P+ product line, TYROLIT defines a new performance level for the flute grinding of tungsten carbide cutting tools. Two different diamond qualities and the innovative bond structure lead either to significantly reduced grinding forces or to a major increase in profile retention. The precision of the machined tools remains at the usual high level. Increased feed speed Easy profiling Extended dressing intervals

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

ECKARDT SYSTEMS GMBH

Germany

60 Series Our medium-sized felt roller lubricators are designed for coil gauges up to 2 mm as well as viscosities up to 120 mm 2/sec (recommended guideline values). Fields of application Tool making: components for milling/turning/grinding machines Expanding metals for use in energy technology, chemistry, medicine Stamped parts for household appliances

Request for a quote

ALKIM PETROKIMYA

Turkey

It is a multi-purpose metal processing oil that is used by being mixed with water in cutting and grinding processes of metals. It is used as lubricator and cooler in light and heavy machining processes of metals such as soft steel and cast iron. It is used after obtaining ideal mixture by slowly adding %5 boron oil into 95% water that does not contain any bacteria, and about whose cleanness you are sure. Note: Under no circumstances should mixture be prepared by adding water into boron oil.

Request for a quote

ORGECO SPOL. S R.O.

Slovakia

Our company specializes in manufacturing sheet metal components according to individual customer requirements and specifications. We utilize state-of-the-art technologies, including laser cutting, CNC precise bending of sheet metal, robotized welding workstations, robotized grinding workstation, and CNC center for rounding and grinding the surface of sheet metal. These advanced tools enable us to deliver products of the highest quality and precision. Whether it's intricate designs or specific dimensions, our technological capabilities allow us to efficiently and reliably meet even the most demanding customer requirements.

Request for a quote

RUF MASCHINENBAU GMBH & CO. KG

Germany

Grinding chips are created by the grinding of metal components. It is a mixture of metal and corundum abrasion in combination with the cutting fl uids being used. By briquetting, the waste is reduced significantly and the briquettes possess a defi ned residual moisture. Thus, the disposal costs are reducedand depending upon the alloy, there is even the opportunity to sell the briquettes with a profit. In most cases, the expensive oil contained in the cutting fl uid can be reused. The briquetting system can already payoff for itself within less than 12 months by processing about 10 to 30 tons of the expensive oil contained in the cutting fl uid per year. Depending on the requirements, our briquetting systems for grinding chips are equipped with hydraulic motors ranging from 4kW to 22kW, and reach a specifi c pressure of up to 3,800 kg/cm². The throughput of the RUF briquetting systems - especially for grinding chips - range from 40 to 350 kg/h.

Request for a quote

NINGBO TOWER INDUSTRY CO.,LTD

China

We almost have all the process in house, including machining(cnc milling, cnc turning, grinding), sheet metal fabrication(laser cutting, stamping, deep draw, bending, tube bending, welding). Please feel free to send us your inquiry.

Request for a quote

NINGBO TOWER INDUSTRY CO.,LTD

China

We almost have all the process in house, including machining(cnc milling, cnc turning, grinding), sheet metal fabrication(laser cutting, stamping, deep draw, bending, tube bending, welding). So we are very suitable for the production of finished products, assembly parts in house, which can have better price and better control on quality also.

Request for a quote

NINGBO TOWER INDUSTRY CO.,LTD

China

We almost have all the process in house, including machining(cnc milling,cnc turning, grinding), sheet metal fabrication(laser cutting, stamping, deep draw, bending, tube bending, welding). So Tower can make finished products, assembly parts like elevator parts in house, which can have better price and better control on quality also.

Request for a quote

ALLIED FOR TECH

Poland

We perform grinding mainly on endless belts, as well as with the use of special grinders and hand-held power tools.

Request for a quote

STALMA S.A.

Poland

Grinding is a precise reduction machining done with the use of griding wheels on special machines that is centreless grinders. Ground bars are characterized by the highest quality among bright steel products and find the application in the production of the most responsible parts of the machinery. Ground bars can be processed from both half-products, drawn or peeled bars. Mechanical properties do not change during grinding.

Request for a quote

SELMACH MACHINERY LTD

United Kingdom

The new AL150HS has a belt speed of 45 m/s due to its unique transmission. When you open the rear cover, you can also use the pipe grinder as a belt sander, ideal for deburring cut profiles. The AL150HS has the option of being operated by means of two handwheels or by means of a lever. Both options are available on the machine. With the AL150HS you can grind material from Ø20 to Ø114.3. The cross support and the slide with rotatable clamp are infinitely adjustable. This allows all pipe profiles to be ground at any desired angle from 20° to 90°. The AL150HS grinds square, rectangular and round pipes with different wall thicknesses and is suitable for all common material types. It is now even easier to adjust the grinding belt with the supplied hex wrench. The grinding belt can be quickly tensioned and grinding rollers can be changed in just a few seconds.

Request for a quote

SELMACH MACHINERY LTD

United Kingdom

The AL100u is operated with a lever. With the AL 100u you can grind material from Ø20 to Ø76.1. The cross support and the slide with rotatable clamp are infinitely adjustable. This allows all tube profiles to be grinded at any desired angle from 30° to 90°. The Al150u has a wider belt (150mm), and can grind material from Ø20 to Ø114.3, and is operated by either a lever or handwheel operation for greater precision. Both machines grind square, rectangular and round pipes with different wall thicknesses and is suitable for all common material types. Thanks to the ALMI belt adjustment system, adjusting the grinding belt is now even easier with the supplied hex wrench. The grinding belt can be tensioned quickly and changing grinding rollers can be done in just a few seconds. Fitted with a deburring table, when a pipe has been ground it can be easily deburred on the deburring table. This makes the machine truly multifunctional.

Request for a quote

SELMACH MACHINERY LTD

United Kingdom

The RVD belt driven pipe notching machine achieves a superior notch finish due to the greater accuracy of the roller and belt notching method. The machine is capable of grinding square, rectangular and round pipes with different wall thicknesses and is suitable for all common material types. The grinding belt can be tensioned quickly and changing grinding rollers can be done in just a few seconds. Fitted with a deburring table, when a pipe has been ground it can be easily deburred on the deburring table. This makes the machine truly multifunctional.

Request for a quoteResults for

Metal grinding - Import exportNumber of results

71 ProductsCountries

Company type

Category

- Grinding - steels and metals (46)

- Abrasive discs (4)

- Polishing - machine tools (3)

- Grinding - machine tools (2)

- Lifts and platform elevators, car (2)

- Adjustment - machine tools (1)

- Flour milling - machinery and equipment (1)

- Import-export - oil (1)

- Mechanical engineering - custom work (1)

- Metallurgy and iron and steel industry - machinery and installations (1)

- SMALL METAL PARTS (1)

- Stamping - steels and metals (1)