- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- metal surface finishing

Results for

Metal surface finishing - Import export

SC PROFINOX SRL

Romania

We provide stainless steel sandblasting and grinding services to obtain smooth and clean metal surfaces. The stainless steel sandblasting procedure is environmentally friendly and highly efficient. For finishing metal surfaces, Profinox provides glass sandblasting services – a procedure that does not contaminate surfaces with iron. This consists in propelling glass granules in the form of a jet at very high speeds directly onto the surface of metal parts. As one of the most important aspects reflecting the quality of a product is the finish of the product itself, our stainless steel sandblasting service enables us to perform highquality surface machining, as sandblasting with glass granules makes it possible to treat even the most difficult to penetrate areas and gives a clean and smooth look to the product. Another important function of stainless steel sandblasting is to significantly improve the final appearance of the product.

Request for a quote

DONGGUAN XINHONGYUAN METAL PRODUCTS LIMITED

China

Metal stamping parts are widely used as metal casing/housing in which all electronics components and PCB board will be assembled, they are designed to be different shapes with various kinds of surface finish, metal material makes the whole light long durability and heat resistance compared to plastic parts, they can be formed by stamping, deep drawing, spinning or TIG welding.

Request for a quote

ESTIMET SP Z O.O.

Poland

In our production plant we have a number of machines and equipment for surface treatment. The "before" and "after" effects are visible in the photos.

Request for a quote

MEVATEC S.R.O.

Czech Rep.

Galvanized structure filled with zinc coated sheet metals. Subsequent surface finish with paint RAL 7035. Delivered without stickers andock. Special safety hole for used textile insertion. Height of the insertion hole handle 1250 mm.

Request for a quote

ORGECO SPOL. S R.O.

Slovakia

As experts in metal fabrication, we specialize in crafting custom brackets and consoles for a multitude of purposes, precisely tailored to our clients' specifications. Our advanced manufacturing facility employs cutting-edge technologies such as laser cutting, CNC sheet metal bending, robotic welding, and robotic grinding to ensure the highest quality and precision in every bracket and console we produce. Whether fabricated from steel, stainless steel, or aluminum, our brackets and consoles are engineered to meet stringent standards of durability and performance. Additionally, we offer a variety of surface finishes including powder coating, anodizing, plating, hot dip, and KTL, providing both protection and aesthetic appeal. At every stage of the fabrication process, from design to finishing touches, we uphold a commitment to excellence, delivering reliable and resilient brackets and consoles that exceed expectations.

Request for a quote

MING XIAO MANUFACTURING CO., LTD

China

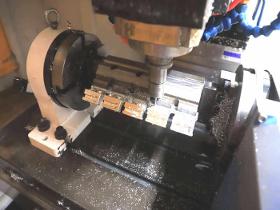

China Ming Xiao Mfg custom CNC milled parts for world clients, equipped 3,4,5 Axis CNC Machining Center several sets, can provide precision CNC milling services with low prices and high quality. High Precision Production. Ming Xiao Mfg custom CNC milling parts in tolerances ranging from +/-0.001″ – 0.005″, custom design depending on customer specs Extensive Material Option. Wide variety of certified materials (over 50 metal and plastic materials) and surface finishes available The common used materials such as Brass,Copper,Aluminum,Steel,Stainless Steel & Plastics. Rapid prototyping. Get prototypes quickly, optimize the entire high-speed milling workflow with advanced milling machines and full equipped CNC milling factory. We also provide precision CNC Turning + Milling Combination Machining Service, Send your inquiry or drawing fast to get an rapid quote in 48 hours. sales@mxmparts.com WhatsApp +86 13780014913

Request for a quote

MING XIAO MANUFACTURING CO., LTD

China

China Ming Xiao Mfg custom CNC milled parts for world clients, equipped 3,4,5 Axis CNC Machining Center several sets, can provide precision CNC milling services with low prices and high quality. High Precision Production. Ming Xiao Mfg custom CNC milling parts in tolerances ranging from +/-0.001″ – 0.005″, custom design depending on customer specs Extensive Material Option. Wide variety of certified materials (over 50 metal and plastic materials) and surface finishes available The common used materials such as Brass,Copper,Aluminum,Steel,Stainless Steel & Plastics. Rapid prototyping. Get prototypes quickly, optimize the entire high-speed milling workflow with advanced milling machines and full equipped CNC milling factory. We also provide precision CNC Turning + Milling Combination Machining Service, Send your inquiry or drawing fast to get an rapid quote in 48 hours. sales@mxmparts.com WhatsApp +86 13780014913

Request for a quote

MING XIAO MANUFACTURING CO., LTD

China

China Ming Xiao Mfg custom CNC milled parts for world clients, equipped 3,4,5 Axis CNC Machining Center several sets, can provide precision CNC milling services with low prices and high quality. High Precision Production. Ming Xiao Mfg custom CNC milling parts in tolerances ranging from +/-0.001″ – 0.005″, custom design depending on customer specs Extensive Material Option. Wide variety of certified materials (over 50 metal and plastic materials) and surface finishes available The common used materials such as Brass,Copper,Aluminum,Steel,Stainless Steel & Plastics. Rapid prototyping. Get prototypes quickly, optimize the entire high-speed milling workflow with advanced milling machines and full equipped CNC milling factory. We also provide precision CNC Turning + Milling Combination Machining Service, Send your inquiry or drawing fast to get an rapid quote in 48 hours. sales@mxmparts.com WhatsApp +86 13780014913

Request for a quote

MING XIAO MANUFACTURING CO., LTD

China

China Ming Xiao Mfg custom CNC milled parts for world clients, equipped 3,4,5 Axis CNC Machining Center several sets, can provide precision CNC milling services with low prices and high quality. High Precision Production. Ming Xiao Mfg custom CNC milling parts in tolerances ranging from +/-0.001″ – 0.005″, custom design depending on customer specs Extensive Material Option. Wide variety of certified materials (over 50 metal and plastic materials) and surface finishes available The common used materials such as Brass,Copper,Aluminum,Steel,Stainless Steel & Plastics. Rapid prototyping. Get prototypes quickly, optimize the entire high-speed milling workflow with advanced milling machines and full equipped CNC milling factory. We also provide precision CNC Turning + Milling Combination Machining Service, Send your inquiry or drawing fast to get an rapid quote in 48 hours.

Request for a quote

MING XIAO MANUFACTURING CO., LTD

China

China Ming Xiao Mfg custom CNC milled parts for world clients, equipped 3,4,5 Axis CNC Machining Center several sets, can provide precision CNC milling services with low prices and high quality. High Precision Production. Ming Xiao Mfg custom CNC milling parts in tolerances ranging from +/-0.001″ – 0.005″, custom design depending on customer specs Extensive Material Option. Wide variety of certified materials (over 50 metal and plastic materials) and surface finishes available The common used materials such as Brass,Copper,Aluminum,Steel,Stainless Steel & Plastics. Rapid prototyping. Get prototypes quickly, optimize the entire high-speed milling workflow with advanced milling machines and full equipped CNC milling factory. We also provide precision CNC Turning + Milling Combination Machining Service, Send your inquiry or drawing fast to get an rapid quote in 48 hours.

Request for a quote

STEROS GPA INNOVATIVE, S.L.

Spain

DLyte eBlast is an electropolishing equipment that offers a stream of solid-electrolyte particles propelled by a non-conductive liquid media to improve the surface quality of metal pieces. This electrochemical surface finishing process is especially designed to surface finish large or heavy parts, or with complex geometries which are difficult to polish by immersion or that require a localized finishing, like welded areas. The new electro-blasting technology is perfect for blind holes, slots, occluded areas and inner channels. This new way to apply electropolishing allows a focused surface finishing, as the media is projected towards a localized area of the piece. DLyte eBlast joins together some benefits in comparison to other surface finishing technologies. The main advantages are that this process can be applied locally in the required area. The process improves the final appearance of metal parts, with no pitting on the metal surface.

Request for a quote

STEROS GPA INNOVATIVE, S.L.

Spain

First installed in July 2019 and improved in 2021, DLyte 10,000 is a modular solution designed for mass manufacturing. It is integrated into any production line where the complete automation of workflows and the production of large batches and parts can be treated efficiently. Based on the patented DryLyte technology, the robot module allows to treat metals and alloys in a fast, and cost-efficient way. To achieve the highest quality results in complex and heavy pieces, it counts with a precise 6-axis mechanical movement, to remove the roughness from the workpieces. DLyte10,000 delivers the full range of electrical parameters, from low to high frequency, parameter concatenation and asymmetric voltage. In addition, it allows the user to search the ideal parameters for its pieces in the library of processes in the Polishing Manager App. The range of applications for the DLyte10,000 are workpieces from the aerospace, energy, oil and gas, shipbuilding, machinery and food industries.

Request for a quote

STEROS GPA INNOVATIVE, S.L.

Spain

DLyte PRO500 are new patented Machines based on patented DryLyte technology for surface finishing of metal alloys for the industry. DLyte provides a solution to the most common industrial metals and alloys. The applications for DLyte finishing technology range from grinding, rounding and deburring to surface smoothing and high gloss polishing of high precision and aesthetic parts.

Request for a quote

STEROS GPA INNOVATIVE, S.L.

Spain

DLyte Desktop Series have been designed in 2021 to improve the work environment of small companies by replacing the manual polishing of metal parts or with equipment that uses hazardous materials for workers. The new equipment gathers all the advantages of any DLyte system currently available and allows any company to access the dry electropolishing technology, including those companies that need a cost-effective solution for metal surface finishing processes. Due to its small dimensions (450 x 521 x 471 mm), its price and the fact of not requiring a special pre-existing electrical or compressed air installation, DLyte Desktop Series are affordable to any kind of company. Moreover, thanks to its intuitive software, it is a good choice for any professional needing to automate metal finishing processes. DLyte Desktop Series are suitable to polish CoCr (with DLyte Desktop Dental) and CoCr and Ti (with DLyte Desktop PRO).

Request for a quote

PI-METÁL

Hungary

We provide customized metal structure production service and contract work. We have a 2000 m2 workspace, dedicated for this kind of work, equipped with the latest, state of the art machinery, including drilling machines, welding machines, milling turning machines, polishing machine and so on. Our technicians are well trained professionals, with lots of experience behind them. We produce tailor made metal structures with finished surface.

Request for a quote

YILDIZ CILA POLISHING COMPOUND AND BUFF MANUFACTURER

Turkey

FOR ALUMINIUM AND STAINLESS STEEL

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

BIBIELLE S.P.A.

Italy

This SCXF X-Flex material can be converted into custom-made sizes at the customer’s request. Main features and benefits: Extremely flexible, does not delaminate even if used with 3 mm diameter contact wheels. Easy to fit on very compact machinery. Recommended applications: Cleaning parts made of stainless steel, aluminium or other metals, satin finishing small surfaces, light deburring or removing TIG or MIG weld beads on hard-toreach places, cleaning marks left by previous operations and removing scale. Work surfaces: Stainless steel, standard or alloyed steel, aluminium, titanium, nonferrous materials and alloys, fibre glass, plastic or plastic reinforced by fibre glass.

Request for a quote

SCHOCK GROUP

Germany

With SCHOCK powder coating we realize high-performance and visually appealing product surfaces with long-term corrosion protection and individual color design.

Request for a quote

MVA D.O.O.

Slovenia

We provide surface preparation and finishing of casted aluminium parts and other metal parts, such as: shot blasting, sand blasting, deburring (trowal), polishing, anodization, galvanic coatings, powder coating and cataphoresis.

Request for a quote

PAF TUBE

Tunisia

PAF offers a wide range of metal props with different load capacities. These are adjustable Props from 0.5 m to 5.00 m opening. Props Specifications: • Plate 120x120x4 mm • Barrel Ø55 thickness 2 mm • Slide Ø48 thickness 2 mm • Mechanically welded adjustment nut • Stamped Ring • Pin Ø12 Captive • Galvanized option available.

Request for a quote

ASSFALG GMBH

Germany

The tub vibratory finishing machine, which has a size similar to a washing machine, with a fill volume of 70 l is our standard machine and is ideal for prototypes and small series. A noise protection cover reduces the noise and makes it possible to work in a workshop. The right and left-hand circulation as well as speed regulation from 1,500 to 3,000 rpm provide for various processing possibilities. The abrasive material and workpieces are rotated through the generated vibration. The desired processing process is created through the contact of grinding bodies on workpieces. The programmable timer rounds off the autonomous work process. The machine has a modular construction and can be expanded with an optional paper filter and separator. Both are controlled centrally through the control panel on the TV 95-SL. We recommend the PF440 paper filter for simple and comfortable water treatment. The S95 separator simplifies the separation of grinding bodies and workpieces.

Request for a quote

ASSFALG GMBH

Germany

The circular dryers are used for stainless drying of all types of workpieces. By using the hot-air blower or the indirect heating through heating rods below the tub, a uniform drying of the workpieces and the drying granulate is ensured. The additional advantage is that it brightens, repolishes and degreases workpieces. Both versions can be configured as individual systems in combination with a new vibratory finishing machine or as a module for an existing vibratory finishing machine. The drying medium and the workpieces are brought into a rotational movement through a generated vibration. The desired drying or post-treatment process are created through the contact of the drying medium and workpieces. The workpieces are automatically screened out of the dryer and transported from the device through the optional manual or pneumatic separation equipment.

Request for a quote

ASSFALG GMBH

Germany

The circular trough vibratory finishing machines are ideal for small and large series for different workpieces. A noise protection cover reduces the noise and makes it possible to work in a workshop. The right and left-hand circulation as well as speed regulation from 1,200 to 1,500 rpm provide for various processing possibilities. The abrasive material and workpieces are rotated through the generated vibration. The desired processing process is created through the contact of grinding bodies on workpieces. The programmable timer rounds off the autonomous work process. We recommend a paper filter or a fully-automatic water treatment plant for simple and comfortable water treatment. The integrated separating equipment simplifies the separation of grinding bodies and workpieces.

Request for a quote

ASSFALG GMBH

Germany

The trough vibratory finishing machines are ideally suited for elongated individual parts and small series. Their advantages lie in the machining of heavy, bulky as well as long workpieces and in the contact-free working of sensitive individual parts in chambers. A soundproof cover reduces the noise level and makes working in a workshop possible. The clockwise and anti-clockwise rotation as well as the speed control from 1,200 to 1,500 rpm ensure a wide range of machining options. The unmanned working process is rounded off by the programmable timer. The system can be expanded with an optionally available paper filter and separator. For simple and convenient water treatment, we recommend a paper filter or a fully automatic water treatment system. The process water is pumped into the trough in doses and cleaned in the return flow via a filter fleece or the centrifugal force.

Request for a quote

ASSFALG GMBH

Germany

The centrifugal plants are suitable for small parts. Due to the higher machining intensity with deburring, they deburr 10-20 times faster than vibratory finishing machines. The centrifugal plant can be planned as a single device up to a fully automatic plant. The grinding bodies and workpieces are accelerated through the rotational movement of the plate washer. Due to the centrifugal force, the workpieces are pressed outward and then transported up on the inner side of the system. Gravity causes these to fall back into the center of the plate washer to be accelerated again. A noise protection cover reduces the noise and makes it possible to work in a workshop. The speed regulation ensures versatile processing options. The programmable timer rounds off the autonomous work process. The machine can be expanded with an optional paper filter and separator.

Request for a quote

ALPHA MANUFACTURING

United Kingdom

Our plant is fully automated and employs industry leading pre-treatment process OXSILAN®. OXSILAN® is a new metal pre-treatment technology that is free from hazardous chemicals and provides superior corrosion resistance for a wide range of metal substrates. OXSILAN® replaces traditional iron and zinc phosphate products. The products provide a superior ecological profile. OXSILAN® is suitable for metal surface treatment, e.g. cold rolled steel, aluminium, zinc coated steels, as well as multi-metal applications.

Request for a quote

ROKVELAS, UAB

Lithuania

At given need our experts can invoke extensive subcontracting. Constructions can be: shot blasted and painted wet; galvanized in various ways;

Request for a quote

PROTEC TRADING GMBH

Austria

English | Deutsch | Español | Português | Français | Italiano | Русский Visit our website for information in your language. Laser-Lotion PROTEC LC20A Anti-spatter agent PROTEC LC20A is optimised to protect sheet metal panels, pipes, profiles and equipment (supports). Protects any type of metal surface from spatter (steel, stainless steel, aluminium, etc.) No silicone, non-flammable and biodegradable. Laser-Lotion PROTEC LC20A ensures increased quality by preventing spatter, providing dry and clean metal surfaces, no reworking required, as well as higher productivity of the laser system as the beam moves more easily following penetration. Another customer benefits are reduction of cleaning efforts and longer lifetime for the grating (support bars) of the flatbed laser system. • No residue and a particularly low level of emissions • Process safety, also during follow-up processes (vibratory finishing, welding, etc.) • Suitable for all conventional coating

Request for a quoteResults for

Metal surface finishing - Import exportNumber of results

32 ProductsCountries

Category

- Finishing of surfaces - machinery (9)

- Milling - steels and metals (6)

- Steels and metals - surface treatment and coating (5)

- Finished Metal Products (3)

- Cutting - steels and metals (2)

- Metallurgy - machinery and installations (2)

- Polishing - steels and metals (2)

- Grinding - machine tools (1)

- Industrial sheet metal work (1)

- Polishing - machine tools (1)

- Public Works (1)

- Steel & Metal Transformation (1)

- Steels and metals - forming and cutting (1)

- Steels and metals - welding and brazing (1)

- Waste sorting - machines and equipment (1)

- Welding, electric - equipment and supplies (1)