- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- removals rate

Results for

Removals rate - Import export

URBSCHAT-TOOLS GMBH

Germany

The question of the ideal milling cutter is dependent upon the material to be machined. A single-tooth cutter is often an advantage for ""soft"" materials (PVC, Perspex, Kömacel, etc), wooden materials (chip- or flakeboard) and non-ferrous metals (soft aluminium, Alcubond, etc.), as the problem of cutting erosion in comparison to clogging recedes. A double flute is better suited to very hard plastics and harder types of aluminium (short chipping). Milling cutters with 4 or more flutes are predominantly used to mill metals. SINGLE-TOOTH MILLING CUTTERS Single-tooth milling cutters are mainly used for machining ""soft"" materials. Their extra large chipping space guarantees an ideal chipping removal and high stock removal rate. MULTI-TOOTH MILLING CUTTERS Multi-tooth milling cutters are used for machining ""harder"" materials. Smoother running is achieved, as several cutting edges are always in contact. The more flutes the tool has, the smaller the individual chippings will be.

Request for a quote

FRIEDRICH AUGUST PICARD GMBH & CO. KG

Germany

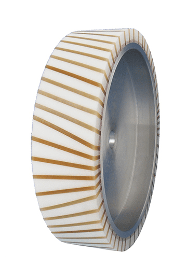

The FAPI–PA MILLED FREQUENCY DAMPED contact disc is the further development of the milled version. Grooves with a groove width-groove depth-web width ratio specially developed by us are milled into the NBR coating of the contact disk. This means that – during the belt grinding process – both the noise level is reduced to a minimum and the material removal rate is increased to a maximum. The total height of the covering can also be selected variably, with the standard height proven in practice being 20 mm. The higher the covering, the more elastic and therefore softer the contact disk surface appears. The contact disks are very aggressive when used due to the grooves they contain. The aggressiveness effect of the contact disk can also be optimized for each application with the milled frequency-damped contact disk by means of an individually optimized groove width-groove depth-web width ratio. We will be happy to advise you in order to find a suitable contact wheel for you.

Request for a quote

FRIEDRICH AUGUST PICARD GMBH & CO. KG

Germany

Uniformly wide lamellae of foamed up Vulkollan® are attached at alternating angles with plastic foam lamellae attached in the spaces between them to the aluminium hub of the FAPI-KS/V SPECIAL. The height of the coating or the length of the lamellae of foamed up Vulkollan® and plastic foam can be varied depending on the application (standard: 25 mm). The longer the lamellae are, the less rigid the material becomes, which in turn reduces the aggressiveness of the contact wheel. Advantages Because of their lamellae of foamed up Vulkollan® and plastic foam, contact wheels of the FAPI-KS/V – series are extremely aggressive contact wheels. Benefits of contact wheels with this design: Maximum removal rate Plastic lamellae provide optimum cooling of the abrasive belt Wear-resistance Oil-resistance Grease-resistance We will be happy to advise you in order to find a suitable contact wheel for you.

Request for a quote

FRIEDRICH AUGUST PICARD GMBH & CO. KG

Germany

The contact disc FAPI-VU MILLED FREQUENCY DAMPED is the further development of the milled version. Grooves with a groove width-groove depth-web width ratio specially developed by us are milled into the contact disc’s foamed Vulkollan® covering. This reduces the noise level to a minimum during the belt grinding process and increases the removal rate to a maximum. The aggressiveness effect of the contact disk can also be optimized for each application using an individually optimized groove width-groove depth-web width ratio for milled, frequency-damped contact disks so that high-performance processes are possible. As with all contact discs in the VU series, there are no signs of fatigue after long, intensive use.The contact discs of the FAPI-VU series are exclusively provided with a coating made of foamed Vulkollan® by its slightly yellowish color. We will be happy to advise you in order to find a suitable contact wheel for you.

Request for a quote

MIKROPOR

Turkey

Mikropor Compressed Air Filters have been designed to meet all requirements of the compressed air filtration world. These air filters provide more comfortable usage for end users with an increased endurance, higher efficiency at lower pressure drop and more port size options.The air filters have four efficiency ratings, removing contaminants as small 0.01 micron at up to 290 psi (20 bar)- 1/4” to 3” NPT/BSP pipe sizes. A protected auto float drain (2 mm orifice) is standard for optimal and reliable removal of liquid contaminants. These air filters have a zero-porosity aluminium and durable epoxy powder-coat finish, along with a corrosion-resistant internal coating for a long service life. Filter combinations are configured to meet specific application requirements. Filters comply with PED and perform as per related ISO 8573 standards. These filters may be equipped with differential pressure gauges for easy maintenance and energy efficiency.

Request for a quote

BALTEAU NON DESTRUCTIVE TESTING

Belgium

It is an essential device which role is to cool the anode of the tubehead when X-rays are produced. Units are compact and powerful to assure both the cooling capacity and the sufficient flow rate to quickly remove calories from the anode.

Request for a quote

BALTEAU NON DESTRUCTIVE TESTING

Belgium

It is an essential device which role is to cool the anode of the tubehead when X-rays are produced. Units are compact and powerful to assure both the cooling capacity and the sufficient flow rate to quickly remove calories from the anode.

Request for a quote

BALTEAU NON DESTRUCTIVE TESTING

Belgium

Oil Air Cooling Unit : It is an essential device which role is to cool the anode of the tubehead when X-rays are produced. Units are compact and powerful to assure both the cooling capacity and the sufficient fl ow rate to quickly remove calories from the anode.

Request for a quote

BIAX - SCHMID & WEZEL GMBH

Germany

This deflectable pneumatic spindle is capable of compensating part and positioning tolerances when machining. This means that it is possible to trace a part contour with constant pressure and achieve uniform removal, even under fluctuating conditions. An optimum application for this system is, for example, the automated deburring of castings or machined components using an industrial robot. Adaptor flange (Order no. 003 012 557) to simplify the mounting of the system is available directly from us. The deflection force is individually infinitely adjustable using air pressure (2-6 bar), even during processing. This enables the removal rate to be perfectly adapted to the thickness of the burr. After deflection the pressurized air piston always returns the tool to the zero position against a positive stop. Hysteresis zero.

Request for a quote

HAINBUCH GMBH SPANNENDE TECHNIK

Germany

A regular check of clamping force is vital for a safe, precise, and productive process. Do you manufacture at the highest possible metal removal rates? Perhaps your clamping device can do more than you think! Those who face tough competition can no longer afford to manufacture with »theoretical clamping forces«. Nevertheless the DIN EN 1550 requires that static clamping force measurement must be performed by the manufacturer at regular intervals. Modular measuring system The TESTit clamping force gauge measures and records the clamping force for O.D. clamping and I.D. clamping and even the draw-in force of hollow tapered shank locations. TESTit consists of two parts: The basic unit, which is the IT module, and the measuring units, which are the TEST modules. You only need the IT module once – regardless of whether you want to measure the clamping force at O.D. clamping or I.D. clamping or the draw-in force.

Request for a quote

BUFFALO MACHINERY CO., LTD.

Taiwan R.O.C.

The high precision, great rigidity and excellent accessibility T-Type (moving column) machine with roto-translation table and high torque built-in spindle provide better metal removal rate. The automatic pallet change system can greatly increase the manufacturing productivity. Applied Straightness Compensation Technology, the linearity of the RAM’s spindle and the accuracy of machining performance can be guaranteed.

Request for a quote

SELMACH MACHINERY LTD

United Kingdom

The metal removal rate of the Kepp belt grinding machines is phenomenal. The grinding power is over fifteen times that of traditional stone grinders. These powerful machines can radius heavy plate and bar in one operation, avoiding the need to crop or burn the required profile prior to ‘dressing’. A 50mm radius in 12mm steel plate is achieved in 10seconds. They have an endless variety of applications for fabricators, blacksmiths and many others in the metalworking industry.

Request for a quote

BUFFALO MACHINERY CO., LTD.

Taiwan R.O.C.

The HM series Horizontal Machining Center is built by T-type construction, which guarantees optimum stability and rigidity for heavy duty machining and is suitable for all kinds of application in any industry. High precision is guaranteed through the determination of cutting performance parameters design. Also equipped with big HP, three-step speed changer, high torque gear-driven spindle, large tool-capacity magazine and excellent chip management as well as high removable rate technology, the model ensures productivity and efficiency of production.

Request for a quote

STARRAG GMBH

Germany

High performance simultaneous 5 axis machining center for aluminum structures Efficient high performance machining requires a rugged machine buildup without weakness. All technical parameters such as axis strokes, forces, torques and accelerations are set according to application requirements. The design of the STC X series has no bottleneck reducing the maximum possible material removal rates. With its design, unmatched productivity is possible. The STC X machine enhancement is ever ongoing. The goal is to continuously increase the customer benefits, i. e. increase productivity, increase accuracy or expand the application options

Request for a quote

STARRAG GMBH

Germany

High performance simultaneous 5 axis machining center for aluminum structures Efficient high performance machining requires a rugged machine buildup without weakness. All technical parameters such as axis strokes, forces, torques and accelerations are set according to application requirements. The design of the STC X series has no bottleneck reducing the maximum possible material removal rates. With its design, unmatched productivity is possible. The STC X machine enhancement is ever ongoing. The goal is to continuously increase the customer benefits, i. e. increase productivity, increase accuracy or expand the application options.

Request for a quote

STARRAG GMBH

Germany

High performance simultaneous 5 axis machining center for aluminum structures Efficient high performance machining requires a rugged machine buildup without weakness. All technical parameters such as axis strokes, forces, torques and accelerations are set according to application requirements. The design of the STC X series has no bottleneck reducing the maximum possible material removal rates. With its design, unmatched productivity is possible. The STC X machine enhancement is ever ongoing. The goal is to continuously increase the customer benefits, i. e. increase productivity, increase accuracy or expand the application options.

Request for a quote

STARRAG GMBH

Germany

Efficient high performance machining requires a rugged machine buildup without weakness. All technical parameters such as axis strokes, forces, torques and accelerations are set according to application requirements. The design of the STC X series has no bottleneck reducing the maximum possible material removal rates. With its design, unmatched productivity is possible. The STC X machine enhancement is ever ongoing. The goal is to continuously increase the customer benefits, i. e. increase productivity, increase accuracy or expand the application options.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

OSMO MEMBRANE SYSTEMS GMBH

Germany

Separation of dissolved gases with membrane degasification Gaseous components can be removed by conventional technologies, like e.g. percolators columns (for example CO2-percolators). Alternatively, gaseous components in water can be removed with very high retention rates by membrane degasification, which is working with hydrophobic membranes and a partial pressure drop. The advantages of the membrane degasification are low operation costs as well a s compact design.

Request for a quote

LMT TOOL SYSTEMS GMBH & CO. KG

Germany

Highly versatile: The MultiFace H45 PRO4 and P45 PRO8 face-milling cutters enable high material removal rates even on lower performance machines. This is achieved with the highly positive cutting edge geometry of the MultiFace H45 PRO4, which has four cutting edges per indexable insert, as well as the positive cutting edge geometry of the MultiFace P45 PRO8 with its eight cutting edges. The easy cutting cutters can therefore be used for many different applications.

Request for a quote

LMT TOOL SYSTEMS GMBH & CO. KG

Germany

High feed and short machining times are the advantages of the LMT Fette MultiEdge 2Feed mini in a nutshell. High removal rates are achieved especially when machining hardened or high-tensile materials, even with large projection lengths. These results are delivered by the proven high-feed geometry of the 9 mm small indexable inserts, their positive rake angle, the new LCK10M cutting material with high carbide content and the TiAlN-based high-performance coating. The machining of high-tensile steels up to 63 HRC and chilled cast iron up to 67 HRC presents no problem. The machining time for one type of tempered steel was almost half that of a competitor tool.

Request for a quote

FISCHER FORTUNA GMBH

Germany

with HSK-A63 tool interface For high-speed cutting (HSC) High removal rates Ultimate precision Compact and high-powered Bearings designed for maximum load and speed Spindles are not sold on the Webshop, but spindle inquiries are accepted. Below on this page are listed the available accessories and peripherals for the MFW2309/27 in the web shop.

Request for a quote

FISCHER FORTUNA GMBH

Germany

with HSK A63 tool interface For high-speed cutting (HSC) High removal rates Ultimate precision Compact and high-powered Bearings designed for maximum load and speed Spindles are not sold on the Webshop, but spindle inquiries are accepted. Below on this page are listed the available accessories and peripherals for the MFW1709/30 in the web shop.

Request for a quoteFISCHER FORTUNA GMBH

Germany

with HSK-A100 tool interface For high-speed cutting (HSC) High removal rates Ultimate precision Compact and high-powered Bearings designed for maximum load and speed Spindles are not sold on the Webshop, but spindle inquiries are accepted. Below on this page are listed the available accessories and peripherals for the MFW-2801 in the web shop.

Request for a quote

FISCHER FORTUNA GMBH

Germany

with HSK-A100 tool interface For high-speed cutting (HSC) High removal rates Ultimate precision Compact and high-powered Bearings designed for maximum load and speed Spindles are not sold on the Webshop, but spindle inquiries are accepted. Below on this page are listed the available accessories and peripherals for the MFWS 2612/18 in the web shop.

Request for a quoteFISCHER FORTUNA GMBH

Germany

with HSK-A63/F80 tool interface For high-speed cutting (HSC) High removal rates Ultimate precision Compact and high-powered Bearings designed for maximum load and speed Spindles are not sold on the Webshop, but spindle inquiries are accepted. Below on this page are listed the available accessories and peripherals for the MFW2320/30 in the web shop.

Request for a quoteFISCHER FORTUNA GMBH

Germany

with HSK-A63 tool interface For high-speed cutting (HSC) High removal rates Ultimate precision Compact and high-powered Bearings designed for maximum load and speed Spindles are not sold on the Webshop, but spindle inquiries are accepted. Below on this page are listed the available accessories and peripherals for the MFW2310/24 in the web shop.

Request for a quote

FISCHER FORTUNA GMBH

Germany

with HSK-A63 tool interface For high-speed cutting (HSC) High removal rates Ultimate precision Compact and high-powered Bearings designed for maximum load and speed Spindles are not sold on the Webshop, but spindle inquiries are accepted. Below on this page are listed the available accessories and peripherals for the MFW2307/24 in the web shop.

Request for a quote

FISCHER FORTUNA GMBH

Germany

with HSK A63/F80 tool interface For high-speed cutting (HSC) High removal rates Ultimate precision Compact and high-powered Bearings designed for maximum load and speed Spindles are not sold on the Webshop, but spindle inquiries are accepted. Below on this page are listed the available accessories and peripherals for the MFW2120/30 in the web shop.

Request for a quote

FISCHER FORTUNA GMBH

Germany

with HSK A63 tool interface For high-speed cutting (HSC) High removal rates Ultimate precision Compact and high-powered Bearings designed for maximum load and speed Spindles are not sold on the Webshop, but spindle inquiries are accepted. Below on this page are listed the available accessories and peripherals for the MFW1920/24 in the web shop.

Request for a quoteResults for

Removals rate - Import exportNumber of results

41 ProductsCompany type

Category

- Machine tools, metal machining - parts and accessories (6)

- Industrial tools (5)

- Milling - machine tools (2)

- Adjustment - machine tools (1)

- Air treatment - equipment and systems (1)

- Broaches - machine tools (1)

- Filters, liquid (1)

- Grinding - steels and metals (1)

- Machine tools - metal machining (1)

- Metalworking - portable power tools (1)

- Milling - steels and metals (1)

- Precision engineering - portable power tools (1)