- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- fillings

Results for

Fillings - Import export

MILKONAL (GROUPE HAITONAL)

Belgium

Enhance your favorite recipes with the rich and creamy texture of Fat-Filled Milk Powder. Perfect for baked goods, sauces, or beverages. Fat/Protein 26/20 28/24

Request for a quote

PATAZA PTY LTD

Australia

Many different varieties available!

Request for a quote

PATAZA PTY LTD

Australia

A unique combination of biscuit, cream filling and chocolate coating, it is an indulgent treat you will want to share with your family and friends. Available varieties: Arnotts Tim Tam Original Arnotts Tim Tam Chewy Caramel Arnotts Tim Tam Dark Arnotts Tim Tam Double Coat Arnotts Tim Tam White Arnotts Tim Tam Messina Choc Mint Arnotts Tim Tam Sunshine Coast Strawberries & Cream Arnotts Tim Tam Murray River Salted Caramel Arnotts Tim Tam Gisborne Orange & Dark Choc Arnotts Tim Tam Murray River Salted Double Coat Arnotts Tim Tam Kensington Pride Mango & Cream Arnotts Tim Tam Dimbulah Mountain Estate Coffee & Choc ArnottsTim Tam Moreton Bay Raspberry & Dark Choc

Request for a quote

PATAZA PTY LTD

Australia

Available varieties: Chocolate, Peanut, Mint, Crunchy Caramel & more! Different sizes available.

Request for a quote

PATAZA PTY LTD

Australia

Different varieties available: Milk Chocolate, Dark, Extra Choc, Marshmallow & more.

Request for a quote

PATAZA PTY LTD

Australia

Available in three different varieties: Mars, Snickers and Twix

Request for a quote

PATAZA PTY LTD

Australia

Salted Pretzels coated in delicious milk chocolate. Perfect as a snack!

Request for a quote

FILLTECH GMBH

Germany

Avery compact and flexible filling system for CO 2/N 2O in combination with other Filltech systems like profiFill or uniFill. Highlights Easy, precise and safe to operate For operation in combination with other Filltech systems Individual solutions on demand Optionally available with integrated pump or for central pumping supply Different attachment parts and filling adapters for the filling of several cylinders in the indicated weight range Additional case for accessories and tools Short set-up time for changing parts Technical Data Filling-range: approx. 50 g - 6 kg/ up to 13 lbs. fill weight Weighing-range: up to 15kg / 35 lbs. Scale division: 0-7 kg -2 g, 7-15 kg - 5 g Dimensions: approx. 600 x 400 x 1200 mm/ 24 x 24 x 47.5 in. Weight: approx. 50 kg/ 110 lbs. Weighing System Two load cells Automatic tare setting Automatic shut-off at target weight Legal for trade Technical Data Filling-range: approx. 50 g - 6 kg/ up to 13 lbs. fill weight Weighing-range: up to 15kg / 35 lbs. Sca

Request for a quote

FILLTECH GMBH

Germany

The profiFill 4.0 is a highly flexible filling solution for CO 2/N 2O or mixed gasses. Through a pre-programmed filling process, which can be easily configured, adjustable individual solutions and consistent documentation can be ensured. The ProfiFill station is a universal filling station. No matter what cylinder your market requires, our equipment can be adapted to your needs. A clamping unit ensures safe and ergonomic filling. Highlights Ergonomic, durable, fast Lifting unit for short cylinders Pneumatic valve open/close unit Maintenance-free DryLin T-Linear guiding 4 load cells for precision and easy calibration Pneumatic filling head Legal for trade Technical Data: Weighing range: 0-150kg / 0-330lbs. Filling range: 6-50 kg / 0-330 lbs. Cylinders: up to 300 x 1800 mm / 11.8 x 70.8 in. Dimensions: 910 x 800 x 2300 mm / 35.8 x 31.5 x 90.5 in. Weight: approx. 300 kg /661 lbs. Weight Scales & Controls 999 storable cylinder types (PLU) Automatic filling process; automatic closin

Request for a quote

FILLTECH GMBH

Germany

The Filltech PackFill is a large platform scale for liquefied gases. Highlights Rugged platform scale 4 load cells OIML class 3 Baseframe to set in concrete Strong weighing platform Connection to various weighing indicators Legal for trade Technical Data Weighing-range: up to 1500-3000kg / 3300 - 6600 lbs. Scale division: 0.5 - 1 kg / 6-12 lbs. Platform dim.: 1500 x 1500 mm / 59 x 59 in. Overall dim.: 1618 x 1618 mm / 63.2 x 63.2 in. Thickness: 100 mm / 4 in. Weight: approx. 200 kg / 441 lbs. Weighing Terminals: Various digital terminals SysTec IT 1000 / IT 3000/ IT 8000 industrial weighing terminal Connection as second scale to other filling units Optional printer and communication interfaces Automatic tare setting

Request for a quote

FILLTECH GMBH

Germany

PicoFill Add-on is a very compact and flexible filling system for CO 2 / N 2O in combination with other Filltech systems like uniFill. Highlights Easy, precise and safe to operate For operation in combination with other Filltech systems Individual solutions on demand Optionally available with integrated pump or for central pumping supply Different attachment parts and filling adapters for the filling of several cylinders in the indicated weight range Additional case for accessories and tools Short set-up time for changing parts Technical Data Filling-range: approx. 50 g - 6 kg/ up to 13 lbs. fill weight Weighing-range: up to 15kg / 35 lbs. Scale division: 0-7 kg -2 g, 7-15 kg - 5 g Dimensions: approx. 600 x 400 x 1200 mm/ 24 x 24 x 47.5 in. Weight: approx. 50 kg/ 110 lbs. Weighing System Two load cells Automatic tare setting Automatic shut-off at target weight Legal for trade Technical Data Filling-range: approx. 50 g - 6 kg/ up to 13 lbs. fill weight Weighing-range: up to 15kg / 35

Request for a quote

FILLTECH GMBH

Germany

A very compact, mobile and user-friendly filling system for a wide range of cylinders with weights up to 6 kilograms. Highlights Variable filling connections Easy, precise and safe to operate Automatic filling process Anodized aluminum frame; stainless steel cover plate Optimal cost/performance ratio Build in pump Legal for trade Technical Data Filling-range: approx. 50g - 6kg/ up to 13 lbs. fill weight Weighing- range: up to 15 kg/ 35 lbs. Dimensions: approx. 600 x 400 x 1200 mm/ 24 x 16 x 47 in. Weight: approx. 50 kg/ 110 lbs. Weighing System Two load cells SysTec IT 1000 industrial weighing terminal Automatic tare setting Automatic shut-off at target weight Manually operated relief with ball valve Optional Filling Connections for Pico-Fill Filling unit for 1/2 in. trapezoid- and side-outlet valves Pneumatic press-on, cartridge filler and other connections on demand

Request for a quote

FILLTECH GMBH

Germany

The UniFill CO 2 / N 2O is an ergonomic filling system for a wide range of cylinders with weights up to 50 kilograms. Highlights Fill connection with quick connector or fast hand wheel Easy, precise and safe to operate Calibratable Many IT communication capabilities Optional printer and / or scanner Optional vacuum prior to filling Integrable pump control Legal for trade Technical Data Filling-Range: approx. 4 – 50 kg/ 9 – 110 lbs. fill weight Weighing range: 0-150kg/ 0-330lbs Scale division: 0-60kg - 20g, 60-150kg -50g Cylinders: up to Ø 300 x 1800 mm/ 11.8 x 70.9 in. Dimensions: approx. 600 x 600 x 1400 mm/ 24 x 24 x 55 in. Weight: approx. 100 kg/ 220 lbs. Weight Scales and Controls Digital, freely programmable SysTec IT 8000 industrial weighing terminal 999 storable cylinder type (PLU) Automatic filling process, manually operated solenoid relief valve Monitoring of fill weight, integrated tare weight control Enhanced software, i.e. topfilling (only the fill parameter must be set,

Request for a quote

FILLTECH GMBH

Germany

Using highly advanced gas filling Small and Medium Enterprises technology is no longer a privilege for large enterprises. Over the last 15 years Filltech developed, in its own research center in the heart of Germany, different standard filling solutions. Through this experience, Filltech has now developed UniFill Complete; a standard gas filling solution for small and medium enterprises, using highly advanced technology. UniFill Complete is a ready-to-use, standardized CO 2 und N 2O gas filling station with a wide filling range for cylinders between 4 and 50 kg. Highlights Easy, precise and safe operation Entry-level, low-cost solution Automatic filling process with bypass valve Pumping set included Integrated pump control Legal for trade

Request for a quote

FILLTECH GMBH

Germany

Customer specific and automatic Filling Stations for several industries and gases. Highlights Highly specialized systems with low overall costs One stop station for all necessary handling Individual solutions on demand 24/7 Back-up support available General capacity: 1000 CO 2 cylinders/hour Filling Options Valve set (fill and relieve) Valve connection Hoses, connections, pipes Weighing Terminals Various digital terminals SysTec IT 1000 / IT 3000/ IT 8000 industrial weighing terminal Connection as second scale to other filling units Optional printer and communication interfaces Automatic tare setting Automatic shut-off at target weight

Request for a quote

NHM LIMITED

Ukraine

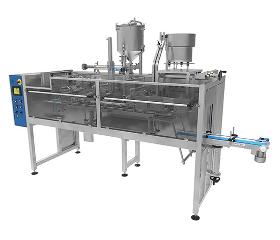

TECHNICAL SPECIFICATIONS: Product to be packed: Yogurt, Lala, Sour Cream, Mayonnaise, Mustard Paste, Honey Dosing volume: 200-3000 ml Speed: up to 20 tubs/min Cup material: Plastic tubs Lid material: Aluminum Voltage: 220/380 V, 50 Hz Power: 0.6 kW/ 1kW Dimensions: 1600 x 900 x 1400 mm Weight: 150 - 500 kg BASIC SCOPE OF SUPPLY: De-nesting of tubs from magazine to transfer mechanism Linear movement of tub Filling of set product volume Placing of plastic lid on tub Leak-proof closing of plastic lid Date coding by contact type ink printer on self-adhesive label Transfer of filled tub on table for ready products TUB FEEDING UNIT Operator puts stack of tubs into infeed magazine (capacity of infeed magazine is approx. 20 pcs.). Tub feeding unit provides piece by piece feeding of tubs on the conveyor. Tub feeding unit provides possibility of stacking for three tub sizes (for 200 ml, 500 ml and 3000 ml).

Request for a quote

NHM LIMITED

Ukraine

TECHNICAL SPECIFICATIONS: Product to be packed: Yogurt, Lala, Sour Cream, Mayonnaise, Mustard Paste, Honey Dosing volume: 150-500 ml Speed, max.: 55-60 cups/min Cup material: Plastic cups Lid material: Aluminum Voltage: 220 V, 50 Hz Power: 2 kW Compressed air, max.: 900 litres/min. at 6 bar Dimensions: 2400 x 1200 x 1900 mm Programmable Logic Controller: Unitronics (Israel) BASIC SCOPE OF SUPPLY: Entire frame & guards of the machine is made of stainless steel SS304 with protective acrylic covers and door handles Parts which are in contact with product made of stainless steel SS316 Drive unit for cup & lid-holder disc (there are pins around the cavity on rotary turret to hold the lids. The cups magazine has a step to hold the cups during discharge) Piston filler for viscous products Cup feeder to turret with vacuum cup Magazine for top aluminum lid loading & lidding unit (precut lids) Lid sealing device “NO cup – NO filling” system Inkjet printer for date coding

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

NHM LIMITED

Ukraine

TECHNICAL DATAPARAMETER Speed, max.50 pouches/min. Filling volume, cm3100 – 1000 ml. (depending on filler) Type of packageready “”Doypack” pouch Packet width, max.200 mm Packet length, max.350 mm Electricals220 V, 50 Hz Power, kW1,5 Air consumption, l/min (0.6 Bar)460 Dimensions, mm2530x970x2190 Weight, kg850 WORKING PRINCIPLE Packaging machine grips empty “Doypack” pouch from a magazine, opens it, fills the product, prints date & seals the pouch. With the help of an orientator (optional) it can orientate and feed spouts to the sealing area and seal the spout vertically on to the pouch. Machine is equipped with parts for working with pouches of one width size. PRODUCTS TO BE PACKED: Food products: mayonnaise, condensed milk, jam, ketchup, tomato paste, sauces, tea, coffee, milk powder, rice, juices, cooking oil, etc. Non-food products: shampoo, liquid cleaning agents, fertilizers, cosmetic cream, window washer, toothpaste, washing powder, etc.

Request for a quote

NHM LIMITED

Ukraine

SPECIFICATION PRODUCTIVITY1500 pouches/hour FILLING RANGE200-1000 ml POWER SUPPLY, MAX220 V, 50 Hz COMPRESSED AIR PRESSURE5 kg/cm2 AIR CONSUMPTION~ 0.2 m3/hour @4 bar PACKAGING MATERIAL1/2/3-layered polyethylene film with black internal layer; thickness – 70-90 microns, width – 320 mm FILLING ACCURACY± 0,5-1% [depending upon bulk density of product, constant product availability in the product tank (for liquids), proper maintenance] OVERALL DIMENSIONS , (WxLxH)670 x 790 x 2570 mm WEIGHT, NET~ 450 kg MACHINE CONSTRUCTION All components are mounted on a single frame. All parts in contact with the product are made from stainless steel AISI 304 . The exterior panels are made of stainless steel AISI 202. Mechanical drive. Protective and hygienic front door. Basic Elements: Film unwinding is provided by rubberized shaft with electric drive and operated by inductive sensors Ultra-violet lamp for film sterilization Liquid Filler CIP connector

Request for a quote

EACTECH®

Portugal

The filling equipment for delicatessen that combines speed and efficiency The Filler EVC-2000 is the equipment you will want as an ally for filling in delicatessen. Chorizo, fresh sausage, sausage, salami, etc. It combines a 10-fin motor feeding system, reducing losses and preventing stains and bubble formation, while controlling the exact size of the portions. A filling solution for optimal results on your production line. The HF-250 hamburger maker is state-of-the-art equipment to produce a wide range of hamburger shapes and sizes. The mold filling system is automatic, guaranteeing uniformity and quality of the final product. Speed and pressure configured on touch panel Greater efficiency Extra income Touchscreen system Control panel with microprocessor Final product quality guaranteed 100%

Request for a quote

A. EBBECKE VERFAHRENSTECHNIK AG

Germany

Big Bag Fill The filling plant for Big Bags and octabins Our Big-Bag filling scales enable the external assignment of filling services onto calibrated Big-Bag scales from storage silos bags or drums. We offer short term useful and flexible filling capacities as a replacement or supplement to your own filling plants. Technical data Big Bag sizes: 0.5-2.5 m³ Weight ranges 50-1,500 kg Product-contacting parts: Stainless steel Feeding: From 100 m³ silos, from palletted bagged goods and drums Number of filling lines 4 Areas of application Filling of Big Bags from silo Filling of Big Bags from bags Refilling of various sizes of Big Bag De-aeration of the product, with subsequent Big-Bag filling Refilling with protective screening Refilling with crushing of agglomerates Refilling with homogenization Refilling with additional admixture of one or more components Refilling with metal detection Prospect for download

Request for a quote

A. EBBECKE VERFAHRENSTECHNIK AG

Germany

Bag Fill Modern, flexible, customer-oriented Technical data Container types Valve bags, open bags, cardboard boxes, drums and fiber drums Container fastening: Plastic bags, welded; paper bags, sewn; valve sacks, valve welded or folded; cardboard boxes / drums tied with liners so they form goosenecks and then fastened with clips Product-contacting parts: Stainless steel, partially electropolished Feeding: From 100 m³ silos, alternatively from Big Bags, octabins, bags or cardboard boxes Number of filling lines 12 Contract filling plants Dosing screw scales, turbine packers, compressed-air packers, vacuum packer, downpipe packers Supplementary: Position of scrap metal boxes as transport containers in reuse of transportation boxes Areas of application Filling of cardboard boxes Filling of fiber drums Filling of valve bags and open bags (5-25 kg bag weight) Filling and palletting of special bags Filling of thin-walled bags (EVA bags) Prospect for download

Request for a quote

A. EBBECKE VERFAHRENSTECHNIK AG

Germany

Liquid filling Solutions, suspensions and pasty masses As part of our contract compacting we take care of contract filling of containers of any type and size for our customer and also the production of suspensions, dispensions and solutions. Through our gravimetric filling plants a semi-automatic filling is realized in Feige filling plants. Furthermore, additional modules can be used, and special solutions are also possible for special liquid filling. The filling is carried out consistently on certified scales. In addition to the technical and economic aspects, we attach great importance to complying with health and safety and environmental guidelines at our filling plants. This way overflow safety devices and drip extraction systems and of course, also gas protective covers protect both employees and the environment from harmful fumes. We also take care of the logistics Due to the high flexibility of our plants, we are able to refill a wide variety of campaign sizes at short notic

Request for a quote

ILLIYYUN SAV. OTO. DAN. LTD.

Turkey

The sample containers are manufactured by our company for the storage of histological and pathological specimens, these containers are 10% buffered.The product provides users with less exposure to hazardous chemicals as it is in a readytouse form. In this way, it facilitates the users' work, and enables more effective and immediate results. It is in superior standards in terms of quality, and the sealed containers are offered in different sizes upon request.

Request for a quote

A. EBBECKE VERFAHRENSTECHNIK AG

Germany

Co-packing customized to your requirements Our plants are ready for you – flexible and efficient! Co-Packing by Ebbecke Verfahrenstechnik Whether Big Bag, octabins, drums, fiber drums, bags, cardboard boxes, buckets, cans or special containers – we work exclusively and without exception with all containers that are used in the bulk material area. At Ebbecke Verfahrenstechnik AG this standard also applies for the size of the container. We process deliveries in silo vehicles, bulk containers and large containers just as efficiently as we fill small containers or containers with a low final weight. As contract compactors, we have been valued partner of the industry for many years. Filling – and much more With our modern machinery we are able to process virtually any bulk and free-flowing materials – whether viscous, pasty, floury, fine or coarse-grained. As reliable contract processors with a wide range of services we don't just fill, but we are ready for our customers as a fully-fle

Request for a quote

SCHÖNWOLF HAMBURG BY 7 SOLUTIONS GMBH

Germany

High quality filling adapters made from corrosion resistant stainless steel for filling breathing bottles of escape equipment (EEBD) to be connected to a conventional 200bar connector.

Request for a quote

SCHÖNWOLF HAMBURG BY 7 SOLUTIONS GMBH

Germany

High quality filling adapters made from corrosion resistant stainless steel for filling breathing bottles of escape equipment (EEBD) to be connected to a conventional 200bar connector.

Request for a quote

SCHÖNWOLF HAMBURG BY 7 SOLUTIONS GMBH

Germany

High quality filling adapters made from corrosion resistant stainless steel for filling breathing bottles of escape equipment (EEBD) to be connected to a conventional 200bar connector.

Request for a quote

CLIPPARD EUROPE SA

Belgium

Clippard's EFB series electronic fill and bleed circuits are a combination of Clippard pneumatic valve components used to inflate a volume or apparatus in one controllable function, and to release or vent pressure in a second controllable function. Fill and bleed circuits are commonly used in many applications where a particular pressure, firmness, or position can be controlled with the addition or venting of pressure. • Compact, robust design • Extremely fast response • Exceptionally long life • Multiple flow and pressure options • Variety of power and connection options • RoHS compliant Read More about the EFB Series Configure & View Products

Request for a quoteResults for

Fillings - Import exportNumber of results

34 ProductsCountries

Company type