- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- steel & metals

Results for

Steel & metals - Import export

MR CO. LTD.

Ukraine

Two methods are used to bend pipes at a certain angle, hot and cold. We provide cold-bending pipe services. Products made of plastic metals and alloys lend themselves well to this technology. Bending pipes by this method is possible only if their diameter does not exceed 100 mm. This type of machining is done manually or through special bending machines. When bending round pipes, it is essential to avoid dents that decrease their inner diameter. The pipes should have smooth bends along a certain radius and a circular shape in the bend areas. Our pipe bending machines allow you to get a quality bend in a few rolls.

Request for a quote

MR CO. LTD.

Ukraine

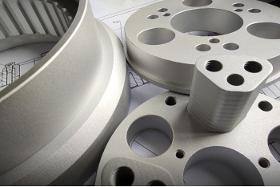

Milling is the process of machining metal with a specific cutting tool, a milling cutter. The milling cutter removes excess material from the workpiece to produce an element of a given shape. Unlike turning, in milling, the workpiece moves forward while the milling cutter rotates. By milling processing, you can obtain a part with a complex shape and geometry from a workpiece. The milling machine is primarily used for demanding tasks such as gear cutting. Our machining workshop is equipped with the most advanced high-tech CNC equipment. We offer our customers full-cycle material processing services, from designing to the protective coating.

Request for a quote

MR CO. LTD.

Ukraine

Sheet metal bending is one of the vital processes of metalworking. The sheet bending workshop of MR Ltd is equipped with the latest European equipment, which provides unsurpassed results. Thanks to CNC technology, the entire folding process, from programming and the tool setting to bending, is very productive. Our equipment and experience allow us to perform work of any complexity, from single orders to large-scale production.

Request for a quote

MR CO. LTD.

Ukraine

By the principle of operation, the coordinate punch press resembles an office paper puncher. The workpiece is pressed against the matrix. After that, a punching tool, the punch, strikes the workpiece with a force of up to 200 tons. In a fraction of a second, the punch and pressure ring return to their original position and the position-sensing mechanism moves the workpiece for the next strike. The capabilities of the equipment are not limited to the production of through-holes. Using punches of different sizes and shapes allows us to perform the most diverse tasks, such as countersinking, dimpling and forming. Modern coordinate punching machines are characterized by high productivity with moderate energy consumption.

Request for a quote

MR CO. LTD.

Ukraine

Hydroabrasive cutting of sheet materials. Does not cause changes in the processed material due to the absence of thermal influence. Maximum thickness of the workpiece: 150 mm. Processing area - 2000×3000 mm. Accuracy up to 0.1 mm (for a thickness of 40 mm).

Request for a quote

MR CO. LTD.

Ukraine

The process is performed in closed chambers, where a jet of millions of glass microbeads, moving in a stream of compressed air, is directed on the product surface using a specialized gun. The abrasive removes all contaminants from the surface without changing the part geometry or damaging the product. It allows even fragile materials to be handled gently with this method. Controlled plastic deformation of the metal surface forms a light work-hardening that improves the service performance of the product. Due to the matting effect, this method is often used for finishing aluminum parts.

Request for a quote

MR CO. LTD.

Ukraine

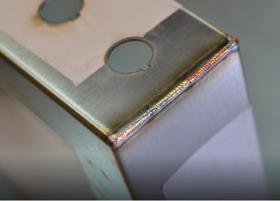

Aluminum alloys are among the materials characterized by poor weldability. Any experienced welder will confirm that to work successfully with aluminum, you need to have a lot of experience and know all the features of this metal. Technologically this process is quite complicated and a lack of experience can lead to manufacturing defects. Due to its high thermal conductivity, low melting point and the presence of a refractory oxide film, welding aluminum requires special equipment. TIG welding with shielding gas using aluminum alloy hard facing rods provides excellent joint quality.

Request for a quote

MR CO. LTD.

Ukraine

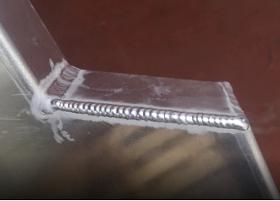

Argon welding is a popular name among people for welding technology, in which welding is performed in a shielding gas environment, most often argon. The gas prevents the metal under welding from coming into contact with the oxygen in the air, preventing oxidation. Inert argon is well suited for this purpose as it is non-toxic and relatively inexpensive. The equipment for argon welding comes in two types, TIG and MIG. In both cases, the machines are equipped with a non-consumable tungsten electrode. The difference is that TIG uses separate hard facing rods, but in MIG, the wire is fed automatically from the spool, for which people often call this method semi-automatic.

Request for a quote

KSL

Ukraine

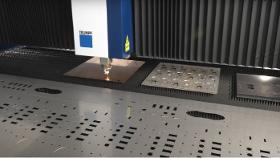

KSL provides quality services in laser cutting of pipes Laser cutting of metal pipes occurs by burning the metal structure with a focused laser beam. With the help of laser cutting of metal pipes, it is possible to manufacture complex parts, the edge of which does not require further processing. We use high-precision German TRUMPF equipment for metal cutting The main characteristics of KSL metal laser cutting: Laser source: 2700W Maximum empty pipe size: 6500 mm The diameter of the round pipe: up to 150 mm Dimensions of the profile pipe: up to 150 mm The maximum thickness of the pipe wall (carbon steel): 6 mm The maximum thickness of the pipe wall (stainless steel): 4 mm The maximum thickness of the pipe wall (non-ferrous metals): 4 mm You can familiarize yourself with us in more detail: Website: ksl-pro.com or ksl.ua Mail: zakaz@ksl.ua Phone: +38 (050) 011 83 29 #pipecutting #lasermetalcutting #lasertubecutting #lasercuttingofmetalpipes #pipelasercutting

Request for a quote

KSL

Ukraine

KSL provides quality metal bending services Metal bending is one of the technological processes of metalworking, the basis of which is the use of a bending press, with the help of which metal parts undergo deformation and become the required shape according to the drawing. With the help of metal bending, you can make a large volume of metal blanks with the required bending angle, without using additional equipment. The main characteristics of KSL sheet metal bending: Depending on the type of material, the length of the product, the width of the matrix and the bending radius, the thickness of the processed metal: from 0.5 mm to 15 mm The maximum bending length is: 2600 mm The working effort of the machine is: 100 tons You can familiarize yourself with us in more detail: Website: ksl-pro.com or ksl.ua Mail: zakaz@ksl.ua Phone: +38 (050) 011 83 29 #metalbending #steelbending #sheetbending #bendmetal #bendingaluminum #bendsteel #bendingmetal

Request for a quote

KSL

Ukraine

KSL provides quality locksmith work Locksmithing is a metalworking process that usually complements other types of metalworking and brings the product to a finished state. Locksmith work is performed with the help of a special manual or mechanized locksmith tool or on various machines. Locksmith work at KSL is performed by qualified specialists who approach their work responsibly and achieve flawless results of accuracy. We can guarantee that the locksmith processing of parts at KSL will be performed in exact accordance with your requirements and in the shortest possible time. The main types of locksmith work used by KSL: Countersinking and thread cutting of various diameters; Drilling of various diameters; Band sawing works; Cleaning of seams after welding; Metal polishing. You can familiarize yourself with us in more detail: Website: ksl-pro.com or ksl.ua Mail: zakaz@ksl.ua Phone: +38 (050) 011 83 29 #locksmithworks #drilling #lpolishing #metalbending #milling

Request for a quote

KSL

Ukraine

KSL provides quality services in Laser cutting of metal Laser cutting of metal occurs by burning the metal structure with a focused laser beam. Laser cutting of metal is characterized by such properties as: high speed of work, accuracy of details, quality of cutting and almost fully automated process. We use high-precision German TRUMPF equipment for metal cutting The main characteristics of KSL metal laser cutting: Laser source: 4000W Maximum sheet size: 6000*2000 mm Maximum sheet thickness (carbon steel): 20 mm Maximum sheet thickness (stainless steel): 15 mm Maximum thickness of non-ferrous metals: 10 mm You can familiarize yourself with us in more detail: Website: ksl-pro.com or ksl.ua Mail: zakaz@ksl.ua Phone: +38 (050) 011 83 29 #metallasercutting #lasermetalcutting #lasertubecutting #lasercutsteel #lasercuttingservices

Request for a quote

KSL

Ukraine

KSL provides quality services of welding of various metals Metal welding is the process of fusing two metal parts together, using heat and pressure to form a strong metal bond. Heat is generated by an electric arc or flame, and pressure is applied using a welding tool. The process of welding is to melt metal surfaces and blend them together to form a homogeneous mass of metal. There are several welding methods, including MIG, TIG, and arc welding. Welding is rightly considered one of the most popular metalworking processes, which is found in many metal products. Main characteristics of KSL metal welding: Semi-automatic welding; Argon welding; Spot welding; Condenser welding. You can familiarize yourself with us in more detail: Website: ksl-pro.com or ksl.ua Mail: zakaz@ksl.ua Phone: +38 (050) 011 83 29 #spotwelding #weldingstainlesssteel #aluminumwelding #metalwelding #tigweldingaluminum

Request for a quote

KSL

Ukraine

KSL provides quality metal powder coating services Powder coating is one of the most popular methods of painting metal products, which uses a special powder consisting of polymer materials and dyes, which is applied to the surface of the object by an electrostatic method or artificial wind. This method allows you to achieve a high quality coating and ensures a long service life of the part. You can familiarize yourself with us in more detail: Website: ksl-pro.com or ksl.ua Mail: zakaz@ksl.ua Phone: +38 (050) 011 83 29 #powdercoatingservices #powderpaint #lpowdercoatpaint #blackpowdercoat #powdercoating

Request for a quote

PETROLINE LLC

Ukraine

Welding is carried out by high-class masters. At their disposal are reliable devices with excellent characteristics. Our employees strictly adhere to the developed technology, so they are able to make aesthetically attractive and durable connections.

Request for a quote

PETROLINE LLC

Ukraine

We perform plasma cutting of varying degrees of complexity. We adhere to a responsible approach to fulfill each order and guarantee the highest quality of products obtained. Or company specializes in: • production of various parts for the subsequent manufacture of metal constructions; • cutting of metal according to the sample, sketch or drawing provided by the customer; • execution of outlines and drawings according to sketches provided by the client; • performing metal cutting efficiently to minimize residuals

Request for a quote

KONTAKT LLC

Ukraine

Contract CNC manufacturing and machining

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

LS PROFI

Ukraine

We offer a ground mounting system of our own production for PV - modules. PV - modules size: 1650 x 992 mm The height of the structure, the angle of inclination, the depth of immersion of the piles are calculated depending on the area of construction, geological research and the terrain. The price includes design, production of a profile with mounting holes, fasteners for assembling the structure.

Request for a quote

LS PROFI

Ukraine

The Сsolar profile is used to create various mounting systems for solar power plants on roofs, when installing ventilation, heating systems and laying electrical cable networks. The Сsolar profile is easy and quick to install , while securely fixing the structure. The Сsolar profile (mounting traverse) is ideal for quick and effective fastening of ventilation ducts, electric trays, water pipes, solar panels. Also, the crosshead can be used in the assembly of crossheads, consoles, supporting structures of any type. The Сsolar profile is made with a thickness of 1.5 mm. The length of the profile is limited only by the transport dimensions. The galvanized Сsolar profile with acceptable price is suitable for influence of high and low temperature, humid environment, solar radiation.

Request for a quote

LS PROFI

Ukraine

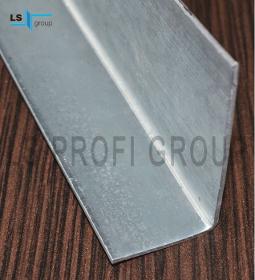

The profile Angle Bar is used to connect other profiles during installation, both support tables and self - supporting structures for arranging a ventilated facade. Most often, the corner is used in the manufacture of arched structures, as well as in other structures where there is some bend. Also, the corner can be used in furniture production, providing even corners. The profile ANGLE BAR are produced by cold forming on roller mills from galvanized coiled steel with a thickness of 0.5 to 3.0 mm, have a wall height of up to 300 mm and, at the request of the customer, can be provided with holes for bolted connections. The length and thickness of the profiles is determined during the design and can be up to 12 m. The thickness of the zinc coating is from 100 to 600 g / m. sq. The profile ANGLE BAR with acceptable price is suitable for influence of high and low temperature, humid environment, solar radiation.

Request for a quote

LS PROFI

Ukraine

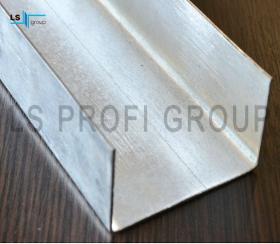

The profile U is used in the manufacture of columns, beams, trusses for the load - bearing frames of buildings. It can be used as roofing and wall purlins, lathing, assembly traverse. U profiles are produced by cold forming on roller mills from galvanized coiled steel with a thickness of 0.5 to 2.0 mm, have a wall height of up to 300 mm and, at the request of the customer, can be provided with holes for bolted connections. The length and thickness of the profiles is determined during the design and can be up to 12 m. The thickness of the zinc coating is from 100 to 600 g per sq. m. The galvanized profile U with acceptable price is suitable for influence of high and low temperature, humid environment, solar radiation. Such profile is used for the construction of warehouses, production workshops, trade pavilions and centers.

Request for a quote

LS PROFI

Ukraine

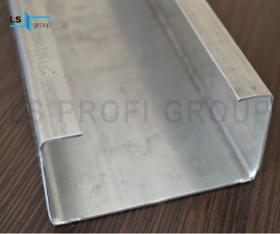

C profiles are produced by cold forming on roller mills from galvanized coiled steel with a thickness of 0.5 to 3.0 mm, have a wall height of up to 300 mm and, at the request of the customer, can be provided with holes for bolted connections. The length and thickness of the profiles is determined during the design and can be up to 12 m. The thickness of the zinc coating is from 100 to 600 g / m2. The galvanized profile С with acceptable price is suitable for influence of high and low temperature, humid environment, solar radiation. Such profile is used for the construction of warehouses, production workshops, trade pavilions and centers.

Request for a quote

FELICITA

Ukraine

Turning with CNCmachines automatic type can make big quanity with a small period of time. We are workinf with stainless steel, steel, aluminium, brass. Threading, drilling, turning and milling made in the same time on one machine

Request for a quote

KAMYANKA MACHINE-BUILDING PLANT

Ukraine

Dimensions up to 600x600x900 mm, weight up to 800 kg. LPC (vacuum cementation) option. Hardening, heating in a gas environment and isothermal cooling.

Request for a quote

HYDROFORMA, LTD

Ukraine

The company "Hydroforma" renders services in the machining of metals and other materials. A large park of machining tools allows us to carry out different types of machining: Turning on the universal machine tools. Turning on CNC machines. Milling. Drill work. Jig Boring work. Grinding processing. Other The works are carried out on machine tools company Doosan, HAAS, NILES and others. Maximum work piece dimensions for processing: for turning operations on the universal machine: diameter 1200 mm, length 12000 mm. for turning operations on CNC machines: diameter 450 mm, length 800 mm. for milling works: 500x1200 mm for grinding operations: 1000*3000 mm

Request for a quote

ANTAREX LLC

Ukraine

Manufacture of metallic structures, bending process, cutting, carving, metal welding.

Request for a quote

YANTOS

Ukraine

Galvanized wire has a wide range of applications. Wire is used for the manufacture of electrical wires, hardware, springs, drills, thermocouples, electrodes, electronic devices and other purposes.

Request for a quote

LAVA-UKRAINE

Ukraine

We specializing in the manufacture of metal stamped parts.

Request for a quoteResults for

Steel & metals - Import exportNumber of results

29 ProductsCountries

Company type

Category

- Stamping - steels and metals (7)

- Bending - steels and metals (4)

- Cutting - steels and metals (3)

- Milling - steels and metals (3)

- Turning - steels and metals (3)

- Welding work - steels and metal (3)

- Steels and metals - machining (1)

- Galvanization - steels and metals (1)

- Steels and metals - forming and cutting (1)

- Steels and metals - welding and brazing (1)

- Perforation of steels and metals (1)

- Heat treatment of steels and metals (1)

- Shot blasting - steels and metals (1)

- Plastic coating - steels and metals (1)

- Precision mechanics (1)