- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- grinding machine

Results for

Grinding machine - Import export

SCHOCK GROUP

Germany

Your project is in the best hands at SCHOCK. Our experienced engineers use state-of-the-art methods to plan all resources and guarantee on-time production. In addition, we supervise your tool over its entire life cycle. In mold and tool making, we work with high-quality milling machines, wire and die-sinking EDM machines, and modern CNC-controlled grinding machines.

Request for a quoteWMC SINTERSTAR AG

Switzerland

For cleaning and dressing grinding wheels

Request for a quote

WMC SINTERSTAR AG

Switzerland

Ceramic whetstones, abrasive files, small files, hand lappers and burnishing wheels, Degussit for the professional!

Request for a quote

WMC SINTERSTAR AG

Switzerland

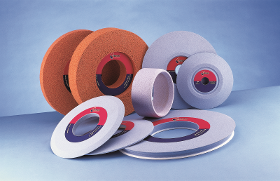

We represent the Sebald company in Switzerland. This company manufactures ceramic grinding wheels in its own production in Germany and has an excellent track record. With this we want to offer our customers an improved service. We look forward to conducting appropriate trials with you.

Request for a quote

ECKARDT SYSTEMS GMBH

Germany

60 Series Our medium-sized felt roller lubricators are designed for coil gauges up to 2 mm as well as viscosities up to 120 mm 2/sec (recommended guideline values). Fields of application Tool making: components for milling/turning/grinding machines Expanding metals for use in energy technology, chemistry, medicine Stamped parts for household appliances

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

SPARX MACHINE TOOLS

United Kingdom

The MCSB/2B-900 is a 900mm wide belt and brush/roll dry working Grindingmaster that is equipped with powerful motors allowing it to process the toughest and heaviest jobs around. R.P.M.1500 Hp/Kw15 + 7.5 kW Typical process applications covered by this machine: Stock removal of multiple individual parts and sheet materials Grain and scratch brush finishing of any material. Sizing and finishing of parts and sheet materials Deburring punched, nibbled, sheared or laser-cut sheet metal parts. Calibrating or keying carbon, rubber, wood or other soft materials.

Request for a quote

SPARX MACHINE TOOLS

United Kingdom

18" x 6" CAPACITY. POWER RISE AND FALL TO WHEEL HEAD. DUST EXTRACTION. OPTI DRESS PANTOGRAPH WEIGHT 850 KG

Request for a quote

SPARX MACHINE TOOLS

United Kingdom

Abrasive belt grinder for the cleaning of corner welds and for the creation of spokes on rectangular pieces such as boxes, at double speed it allows to work angles of maximum height 145 mm on a support surface adjustable in height and inclination. Spoking system with two-roller fork on which abrasive belt slides, the adjustable oscillation of the rollers both in the angle and in the fulcrum allow to obtain the desired radius from R = 1 to R = 10 or cleaning with a sharp edge. The adjustment of the plane by means of a handwheel guarantees the best exploitation and correct bending of the belts of adequate width for the height of the piece.

Request for a quote

SPARX MACHINE TOOLS

United Kingdom

The Kuhlmeyer ZBS Twin Belt Grinding Machine is built for the roughing and finishing on welded edges, corners and surfaces on flat and mid-size workpieces out of steel, stainless steel, and aluminium, i.e. doors, frames, cabinets, housings, hoods, furniture parts, frame parts in automotive and aircraft – manufacturing, round bins, cylinders, heaters etc.

Request for a quote

ALI URAS GIDA TARIM

Turkey

Freshly collected foods from all over Turkey are dried in sterile ovens. Then it is processed into powder by grinding machines and packed according to sterilisation and standardisation rules and shipped to every corner of the world.

Request for a quote

MACHINERY CO. LTD

Canada

The host adopts electromagnetic speed regulation or frequency conversion speed regulation, stable and strong operation, suitable for various viscosity; hydraulic and mechanical lifting forms, free lifting and rotation, adapting to various positions; general explosion-proof configuration, safe and reliable, simple operation and maintenance; continuous productivity Strong, the materials can be quickly dispersed and dissolved, the dispersion effect is good, the production efficiency is high, the operation is stable, and the installation is simple. There are different functions and models for the viscosity and production volume of different materials.

Request for a quote

MACHINERY CO. LTD

Canada

Horizontal closed conical bead mill is the powder material for solid - liquid dispersion grinding of the machinery. Widely used in coatings, dyes, inks, Light-sensitive material,medicine,food and other industries. Horizontal sand mill design novel, compact structure,double end-face mechanical seal, the material in the closed state of production, effectively prevent the material dry, skinning and solvent evaporation, and the machine does not have a special installation basis, you can change the installation location at any time as needed. The sander also has a dispersion and mixing effect while grinding the material. Scope of application -- -Food: cocoa, chocolate, nut butters, sauces, mayonnaise, dressings, etc. -- -Making paint: ink, pigment, paste, filler, dye, carbon black.Dyno Mill horizontal ink bead mill homogenizer paint grinding -- -Chemicals: pharmaceuticals, cosmetics, plant protectants, detergents. -- -Minerals: kaolin (China clay), ceramic mud, fireclay

Request for a quoteResults for

Grinding machine - Import exportNumber of results

13 ProductsCompany type