ILUDEST DESTILLATIONSANLAGEN GMBH

Germany

Manufacturer/ Producer

ILUDEST DESTILLATIONSANLAGEN GMBH

Germany

The instrument has a capacity of 6 litres of solvent mixture with a throughput of up to 1 l / hr (e.g. when recovering Xylene). A microcomputer controller holds up to 100 programs as well as monitoring the distillation process for normal and safe operation. Variable reflux ratios and equilibrium times are possible so that the operator has maximum flexibility to design a program for optimal efficiency. Other capacities are available upon request.

Request for a quote

ILUDEST DESTILLATIONSANLAGEN GMBH

Germany

Because of the thermal sensitiveness of products, this separation method is applicable. The medium which is to be distilled is exposed only for a very short time to the heating substances because the film, which is created by the wiper, can evaporate very quickly. The residence time of medium on the heating surface is a matter of seconds, thus essentially less than in a reboiler flask, circulating evaporator etc. Evaporators in borosilicate glass 3.3 are available with heat exchange areas 0.02…0.8 m². Alternative design versions in stainless steel for higher throughputs are available upon request. Please equire.

Request for a quote

ILUDEST DESTILLATIONSANLAGEN GMBH

Germany

Because of the thermal sensitiveness of products, this separation method is applicable. The sample to be distilled is exposed only for a very short time to the heating substances because the film, created by the wiper, can evaporate very quickly. The residence time of medium on the heating surface is a matter of seconds, thus essentially less than in a reboiler flask, circulating evaporator etc. The evaporated product (operation pressures down to 103 mbar and temperatures up to about 300°C) has to pass a “short path” to the condenser only, which is located in the middle of the evaporator. Evaporators in borosilicate glass 3.3 are available with heat exchange areas 0.02…0.8 m². Evaporators in stainless steel can be heated by a heating jacket to higher temperatures with more heat transfer area for higher throughputs.

Request for a quote

ILUDEST DESTILLATIONSANLAGEN GMBH

Germany

The unit for the liquid/liquid extraction operates in a countercurrent flow and is designed as a pulsed column with sieve trays and packing material alternatively. The working principle of this unit is based on the fact, that the two liquid phases are pressed through the holes of each sieve tray or through the packing respectively, forced by the used pulsation, thus one phase will be dispersed into the other. The large contact surface which will be formed by this specific design, makes the product exchange between the two phases highly efficient. During the return travel of the pulsator, the drops previously dispersed are agglomerating into a homogeneous phase. The light phase will be fed into the system at the lower end of the column, while the heavy phase is entering the tower at the upper end. Due to the gravitation, supported by the said pulsation, both phases are passing the column in countercurrent way and are withdrawn at the opposite ends.

Request for a quote

ILUDEST DESTILLATIONSANLAGEN GMBH

Germany

For liquidliquidextraction according to the MixerSettlerprinciple, design acc. to Dr. E. Müller (Lurgi). With screw stirrer for intensive mixing of the phases, especially suited for metallic salt extraction. Pumping capacity and residence times are changed by adjusting the stirrer speed. An additional advantage of the unit is the application for extractions during which reactions of considerable density changes occur. Typical applications for this universal apparatus are metal salt extractions mixtures with low surface tension if the dispersed phase coalesces with difficulty if variation in residence time of the phases occur in the extraction stages if reactions are expected during the extraction process if considerable changes in density are expected as a result of extraction

Request for a quote

ILUDEST DESTILLATIONSANLAGEN GMBH

Germany

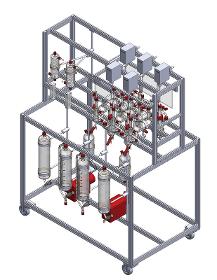

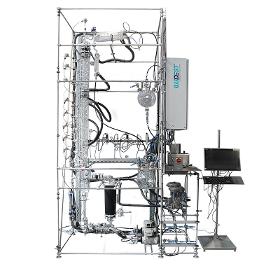

ILUDEST® designs / manufactures a comprehensive range of Teaching Units for the Thermal Process Engineering, e.g. Continuous distillation Thin film evaporation Short path evaporation Pulsed counter current extraction Absorption/desorption Residence time determination (reactor/cascade) etc. Other types and/or customized versions are available upon request.

Request for a quote

ILUDEST DESTILLATIONSANLAGEN GMBH

Germany

ILUDEST® designs / manufactures a comprehensive range of Teaching Units for the Thermal Process Engineering

Request for a quote

ILUDEST DESTILLATIONSANLAGEN GMBH

Germany

Comprehensive range of microprocessor operated units for various control modes/functions. The indication and modification of all set points and actual values is done via touchscreen LCD. With optional Ethernet interface for the communication with a PC and CANBUS for the connection to other controller types.

Request for a quoteManufacturer/ Producer

Dachdeckerstrasse 1

97297 Waldbüttelbrunn - Germany

europages also recommends

A selection of companies related to the activity:

A selection of products that might interest you

BÜRKLE GMBH

Germany

With Novartos Multi double sampling, a double multi-point sample can be taken from multiple predefined sample zones. Depending on the lenght, four, seven or nine sample chambers are each fitted with two sample inserts for the double sampling.

Request for a quote

BÜRKLE GMBH

Germany

With Novartos Multi triple sampling, a triple multi-point sample can be taken from multiple predefined sample zones. Depending on the length, four, seven or nine sample chambers are each fitted with three sample inserts fot the triple sampling.

Request for a quote

BÜRKLE GMBH

Germany

With the thread adapter made of high-quality stainless steel 1.4301 (304) a pump, a drain cock or any other connection with thread G 2" (Whitworth pipe thread) can be screwed onto a container with G 1 1/2" thread. The thread adapter adapts and thus compensates for different thread shapes. The drum adapter ensures that decanting is liquid-tight; a seal made of ePTFE reliably seals the connection. The thread adapter made of stainless steel is electrically conductive and highly chemically resistant. It can therefore be used for filling solvents and other flammable liquids (e.g. alcohols, petrol, diesel etc.) as well as for weak alkalis and acids.

Request for a quote

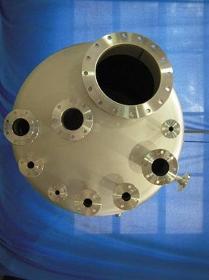

KASAG SWISS AG

Switzerland

The task of storing liquids hazardous to water or to their processing must be handled responsibly. In the building of the corresponding process containers, storage tanks, stainless steel containers, different factors must be taken into consideration. They are designed according to regulations, such as PED (AD-2000, SVTI, EN13445) or according to special standards, such as the Basel chemical standard BN76 and manufactured in stainless steel. Process containers and storage tanks have half-pipe coils, jackets or laser-welded structures (pillow plates) for heating and cooling purposes. KASAG is the competent place if you are looking for replacement, modification, extension or reconstruction of complete tank plants. We will share your responsibilities.

Request for a quoteRequest for quotes

Create one request and get multiple quotes form verified suppliers.

- Only relevant suppliers

- Data privacy compliant

- 100% free

![Distillation Control Unit ILUDEST® [DC / MIC]³](/filestore/vig280/opt/product/44/e3/dist-control-unit-iludest-dc-mic_1_e7dfd410.jpg)