- europages

- >

- Silicones

- >

- STARLIM SPRITZGUSS GMBH

- >

- products

STARLIM SPRITZGUSS GMBH

Austria

Manufacturer/ Producer

STARLIM SPRITZGUSS GMBH

Austria

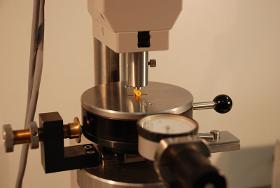

starlim//sterner's work is process-related, thus eliminating sources of error wherever possible. The zero fault philosophy is a clear commitment to our customers and guides all starlim//sterner workers who process their daily tasks. Fault-avoiding approaches such as FMEA, advanced quality planning (APQP), consistent monitoring of production processes and stable processes with high CPK ratings currently result in a failure rate of < 1 ppm. We envisage a further improvement of the ppm rate by continuously introducing improvements. Certified management systems make sure that the zero-fault philosophy is realized throughout the group's entire organization. We will not rest on our laurels, but work continuously on the improvement of our products, our services and our performance. If you want to send us commentaries, complaints or simply a few encouraging words, send them to this e-mail address: customer-service[at]starlim-sterner[dot]com.

Request for a quote

STARLIM SPRITZGUSS GMBH

Austria

We talk about joint quality management. That does not only concern the department responsible for that particular task but all levels of the company, i.e. several departments jointly. When a new customer project is being started or when an existing project is worked on, technical departments join in to discuss the project. Inquiries, feasibility studies, new orders, questions on how to meet customer's requirements, complaints, … all these topics are discussed during project discussions with those responsible. Sales people, quality control staff, designers, cost calculators, tool makers, process technicians – all these specialist join together, are integrated into the project and work on it together. It is this project-oriented approach that makes it possible for us to give the customer reliable information.

Request for a quote

STARLIM SPRITZGUSS GMBH

Austria

starlim//sterner specializes in the processing of silicone. Only high-temperature-curing and addition-curing silicone types (HCR) are being used. Examples Liquid silicone (LSR) Oil-bleeding liquid silicone (LSR) Solid silicone (HCR) Fluorine-solid-silicone (FSR) Fluorine-liquid-silicone (FSL) We mainly use material supplied by: Wacker Chemie AG, Munich/Germany Momentive Performance Materials GmbH, Leverkusen/ Germany Biesterfeld Interowa GmbH & Co KG, Vienna/Austria Implants: starlim//sterner makes no long-term implants. starlim//sterner manufactures short-term implants that do not remain longer inside the human body than 30 days (medical products class IIa).

Request for a quote

STARLIM SPRITZGUSS GMBH

Austria

Liquid-silicone – the material processed by starlim//sterner on over 200 injection molding machines is a multi-facetted material. Good properties and steady improvements allow for a big range of applications for liquid silicone. It has become an indispensible material for many components used in daily life. A summary of the most salient features: Shore A hardness ranging from 5 to 85 Seven standard colors are available, liquid silicone may be dyed at any color. starlim//sterner has defined seven standard colors from the whole range. Temperature resistance: long-term (entire life-span of product) within the range from -50°C to 180°C and short interval 300°C (depending on the material: several hours). Remains flexible at low temperatures. Liquid silicone remains elastic despite big differences in temperature High level of extensibility (up to 1000%) High tear resistance and high value of compression set Good ozone and UV resistance which translates into good weathering properties and

Request for a quote

STARLIM SPRITZGUSS GMBH

Austria

Solid silicone (HTV) is physiologically inert and may be used universally. "Solid" turns out to mean highly elastic – solid silicone is an auto-curing single component silicone caoutchouc. It is supplied in bales, blocks or strips and has good material properties. A summary of the most important properties: Shore A hardness ranging from 30 to 80 Seven standard colors are available, liquid silicone may be dyed at any color. starlim//sterner has defined seven standard colors for solid silicone. Temperature resistance: long-term (entire life-span of product) within the range from -50°C to 180°C and short interval 300°C (depending on the material: several hours). High temperature flexibility, solid silicone stays elastic even if temperatures vary greatly High level of extensibility (up to 1000%) High tear resistance and high value of compression set Good ozone and UV resistance which translates into good weathering properties and ageing resistance Low inflammability, flash point at 750

Request for a quote

STARLIM SPRITZGUSS GMBH

Austria

starlim//sterner is a recognized partner for the automotive industry and supplies OEMs with silicone and compound parts. There is no longer any car on the road without a starlim//sterner product. Most of the times it is hidden away under the motor hood and is present in plug connectors as sealant. Without such starlim//sterner products the car would be subjected to electrical shortages. Moisture would enter inside and incapacitate the vehicle. Production of silicone and multi-material parts for the automotive industry. For the auto-industry we produce amongst other things Sealing mats and collector seals Seals for plug connectors Highly transparent lenses Radial seals Single strand seals O-rings Protective tubes for spark plugs Steering wheel switches with finished surfaces Various customized solutions

Request for a quote

STARLIM SPRITZGUSS GMBH

Austria

starlim//sterner manufactures components for the life science industry. This includes everything that comes into contact with humans. Examples are: the medical industry, pharmaceutical industry, laboratory and diagnostics supply, infant articles industry, the food industry, cosmetics and much more. Our production facilities represent the state-of-the-art and our clean room guarantees an optimum of manufacturing quality. Cleanness, hygiene and controlled and stable processes. Production of silicone and multi-material parts for the life science industry. For the life science industry we produce amongst other things: Metering valves for food packaging, such as ketchup bottles Seals for infusion systems O-rings for dialysis filters Components for hearing aids Tourniquets for blood sampling Suckers for infant soothers Nipple shields for mothers Valves for inhalation appliances Components for medical appliances

Request for a quoteeuropages also recommends

A selection of companies related to the activity:

A selection of products that might interest you

ARUBIS

Belgium

Arubis produces corrugated rubber sleeves in Rotex® and Sweco® designs, on top of custom made styles on demand. This large variety of molded corrugated sleevesensures a tight seal for your specific industry type. Manufactured in any custom size and diameter to create a tight seal Can be FDA approved High quality and long lifetime Industry type Arubis corrugated sleeves can be used in many industry types. Most commonly used as connections in gyratory and vibratory machines, Arubis provides sleeves with outstanding wear and durability. Other common applications include screeners, conveyors, hoppers and dryers. Custom sizes on demand The standard Rotex® and Sweco® designs ensure a tight fit on any manufacturing process using these standards.

PROGRESS SILICONES

France

Progress Silicones cuts parts to customer specifications from sheets, profiles, rolls and more by die-cutting, cutting, drilling, vibrating blade or guillotining machine.

Request for a quote

PROGRESS SILICONES

France

PROGRESS SILICONES PRODUCES O-RINGS FOR ALL SECTORS OF INDUSTRY. French and international standards Custom-made O-rings from one-off items to large series. Hardness from 5 to 90 Shore A depending on the material: Silicone FPM / FKM (fluorocarbone) EPDM (ethylene-propylene-diene monomer) NBR (acrylonitrile-butadiene) HNBR (hydrated acrylonitrile butadiene caoutchouc) CR (polychloroprene) We provide materials in various grades by prior request: Contact with food:FDA, BFR Contact with water: KTW, ACS, NFS61, WRAS, W270 Pharmacopoeia: USP class VI, ISO 10993... Implantable < 29 days Aeronautics ROHS REACH Secondary services: Special packaging: blister, kraft paper, etc. Packs for O-rings Personalised labels Please contact our Sales department for further information on our O-rings.

Request for a quote

XIAMEN NINESUN IMP. & EXP. CO., LTD

China

Product name: Silicon Carbide SIC Nanopowder 90% Place of Origin: China Application: refractory materials Shape: Powder Material: silicon carbide Chemical Composition: Si2O3 Color: Black SiO2: 90%min Usage: Metallurgy Deoxidizer Package: 1 Ton/bag Payment: L/C T/T Supply Ability: 1000 Ton/Tons per Week Lead Time:15-30days Port of shipment:Xiamen,China Applications 1.metallurgical deoxidizer 2.high temperature resistant materials 3.as abrasive,abrasive tools can be used to such as grinding wheels,whetstones,grinding head, sand tile etc Advantages 1.corrosion resistance,high strength,high hardness, 2.good wear-resisting performance,resist to shock 3.stable chemical performance,high thermal conductivity,high resistant temperature

Request for a quoteRequest for quotes

Create one request and get multiple quotes form verified suppliers.

- Only relevant suppliers

- Data privacy compliant

- 100% free