- europages

- >

- Pumps

- >

- VILLINA LLC

- >

- products

VILLINA LLC - Manufacturer of pumps for the oil, gas and chemical industries

Russia

Manufacturer/ Producer

VILLINA LLC

Russia

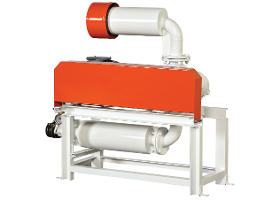

Vertical semi-submersible pumps are designed to solve the problem of pumping liquid out of a tank when a part of the pump is within the pumped medium. Pump units are used with the engine speed up to 3,000 rpm. Therefore, the temperature conditions for semi-submersible pumping units are up to 250 degrees. Centrifugal semi-submersible pumps are widely used both in petroleum refining (petroleum and drainage pumps) and the chemical industry, and in the food industry. They are used for transit of various liquids and mixtures including explosive and flammable fluids (oil and gas products, etc.). Semi-submersible pumps are in between surface and submersible units and combine all their advantages, nevertheless, a semi-submersible pump is not designed to carry out specialized tasks for which these two types of units were created. Semi-submersible pumps consist of an electric motor, a working section and immersed sections. The engine is placed on a base plate

Request for a quote

VILLINA LLC

Russia

Villina-GNVCP-2T type vertical electric semi-submersible pumping units are designed for transit in stationary conditions of neutral, corrosive, toxic, as well as explosive and fire hazardous liquids, the vapors of which can form explosive mixtures with air. These are used in gas, petrochemical, petroleum refining and other industries. The vertical semi-submersible pump – the pump part is fully or partially in the pumped liquid. The unit consists of a pump part, drive sections, a base plate, a device that transmits torque from the drive, an electric motor (drive). The ground part comprises a console fastened to the base plate, an electric motor mounted and fastened to the console, and a mechanical seal support system fastened to a base plate. The semi-submersible part comprises drive sections fastened to the base plate, an elastic coupling body connected to the lower drive section, a pump connected to the elastic coupling body and a discharge line.

Request for a quote

VILLINA LLC

Russia

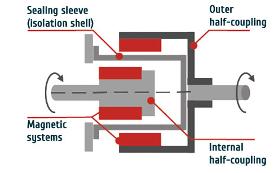

The main parts of magnetic couplings used in GNVC series vertical pumps are the driving (external) and the driven (internal) half couplings, and a sealing sleeve between the half couplings. The exceptional reliability of Villina magnetic couplings is the result of a high-tech design: the enclosed capsular design of the half couplings (enclosed body) secures the magnetic systems from environmental effects; the use of special adhesives allows for fast fixture of domestically produced permanent magnets based on rare-earth elements on the half coupling ferrules; double protection against overheating and demagnetization is implemented using the temperature sensor of the sealing sleeve, which is triggered when the maximum acceptable operating temperature is exceeded by 20 to 50°C, with the use of magnets with Curie point of more than 100°C higher than the maximum acceptable operating fluid temperature; the sealing sleeve made of high-strength Hastelloy alloys

Request for a quote

VILLINA LLC

Russia

The design of an electric pump section is similar to the design of a standard vertical electric pump with a GNVC series magnetic coupling, which allows for the use of already proven technical solutions: impeller blades with curved surfaces create an angle of attack and partially allow for switching to the laminar mode of wall-adjacent flow on their surface and provide more efficient deflection of liquid to the periphery; a closed type impeller has a higher efficiency and longer service life compared to open and semi-closed impellers; bell-type fit of the impeller on the pump shaft precisely keeps the geometric position of the impeller with respect to the guide vanes; the vertical position of the shaft resting on a heavy-duty carrying cushion in the vertical plane, and sleeve type bearings in the horizontal plane help prevent sagging of the shaft, as for instance, in the horizontal design of the pump, and play and runout; the use of sleeve type bearings

Request for a quote

VILLINA LLC

Russia

During the construction of an industrial facility, much attention is paid to the strength of the service pipelines fasteners. It is also necessary to provide reliable connection of all units of industrial equipment with the pipelines. In this case, it is not always possible The use of a permanent welded joint is not always possible, therefore, there are various types of weld-free tight joints. FLANGE JOINT COMPONENTS At present, one of the most effective connections used in industrial facilities is a flange joint. This is an airtight connection that provides high structural integrity, consists of two flanges, fasteners (studs or bolts, washers, nuts) and gaskets. An important matter in choosing a set of flanges is tightness. The gasket material must have good elasticity, strength, resistance to the operating temperature conditions and to the media with which direct contact is expected. For flange joints, Villina company uses the following types

Request for a quote

VILLINA LLC

Russia

The magnetic coupling drives for stirring devices are designed to be installed immediately into the tank and provide the necessary stirring of the product. The drive is electrically driven and consists of two half-couplings (driven and driven magnetic half-couplings), bearing assembly and the stirring device itself. Stirring devices (mixers) are of several types: paddle, anchor, propeller, U-type, etc. We develop and supply turn-key solutions for our customers. Magnetic coupling drives for stirring devices are custom-tailored for each specific customer's application in accordance with the sketches provided or according to the parameters specified in the questionnaire form.

Request for a quote

VILLINA LLC

Russia

Magnetic couplings are used as transmission mechanisms in modern pumps, which makes it possible to obtain a qualitatively new 100% tight device without making essential changes to the design of the electric drive and the wet end of the pump. At present Villina offers GNVC, GNGC and GNVC-P series vertical, horizontal and semi-submersible centrifugal pumps with magnetic couplings, designed for pumping explosive and flammable, toxic and corrosive fluids (petroleum products, alkalis, acids, alcohols, etc). PURPOSE Magnetic couplings for Villina centrifugal pumps allow for transmission of torque from the electric motor to the pump shaft using magnetic fields generated by permanent magnets instead of mechanical engagement devices. At the same time, there is no need to withdraw the shaft from the pump wet end to the drive device, therefore the wet end can be made in the form of a completely sealed system free of leaks which are typical for pumps with mechanical shaft seals.

Request for a quote

VILLINA LLC

Russia

We offer bowls and impellers for centrifugal pumps made of: steel 20H13L, steel 12H18N9TL, steel 12H18N12M3TL according to GOST 977-88.

Request for a quote

VILLINA LLC

Russia

We supply thrust bearings (bearing plates, end thrust bearing), rolling bearing (combined type) and support bearings (plain journal bearings) made of the following material: tungsten carbide (WC); silicon carbide (SiC), VK8 alloy, etc.

Request for a quote

VILLINA LLC

Russia

We supply rubber sealing O-ring comforming with GOST 9833-73 “Rubber sealing O-rings”. We produce: flat paronite and fluoroplastic gaskets in accordance with GOST 481-80 high-temperature TEG (thermally expanded graphite) gaskets according to STO 00220575.001-2007 heat-resistant spiral-wound gaskets according to GOST R 52376-2015

Request for a quoteeuropages also recommends

A selection of companies related to the activity:

A selection of products that might interest you

POMPES JAPY

France

Body, flange, screw and shaft: stainless steel Couplings: stainless steel (nylon as an option with code -A) Membrane and valves: made of a hydrocarbon-resistant elastomer (Neoprene as an option with code -A) Lever: zinc-plated steel with a rubber handle, 1 metre in length

Request for a quote

PARSMEGA MAKINA

Turkey

Blower pumps are used in mill systems to meet the air required by the supersonic filter and to transport products vertically and horizontally.

Request for a quote

FOCQUET

Belgium

"We have different solutions at the industrial pump level. We offer two solutions in our product range: thermal oil transfer or water transfer. In the pumps offered by Focquet, we have mainly bare shaft pumps mounted on base, monobloc pumps and in-line pumps. The pump department is specialized in the overhaul of pumps of all brands and the assembly of pump units with a very short delivery time. We have a great deal of expertise and know-how in industrial pumps and a large stock of spare parts in order to respond to our customers' emergencies as well as possible."

Request for a quote

FOCQUET

Belgium

"We have different solutions at the industrial pump level. We offer two solutions in our product range: thermal oil transfer or water transfer. In the pumps offered by Focquet, we have mainly bare shaft pumps mounted on base, monobloc pumps and in-line pumps. The pump department is specialized in the overhaul of pumps of all brands and the assembly of pump units with a very short delivery time. We have a great deal of expertise and know-how in industrial pumps and a large stock of spare parts in order to respond to our customers' emergencies as well as possible."

Request for a quoteRequest for quotes

Create one request and get multiple quotes form verified suppliers.

- Only relevant suppliers

- Data privacy compliant

- 100% free